Linear beam shaping optical system

A beam shaping, optical system technology, applied in optics, optical components, installation, etc., can solve problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

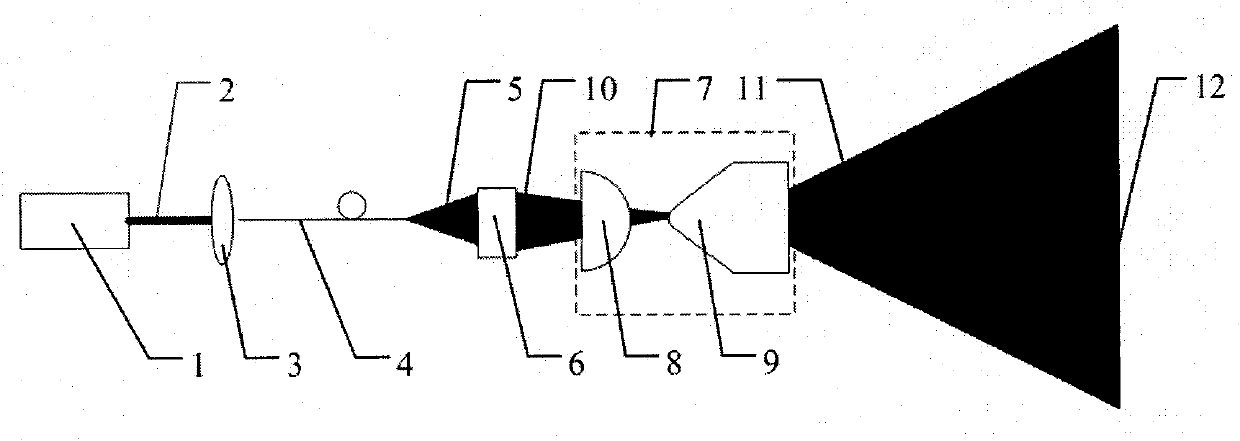

[0015] The present invention combines the attached figure 1 , its technical scheme is described in detail as follows:

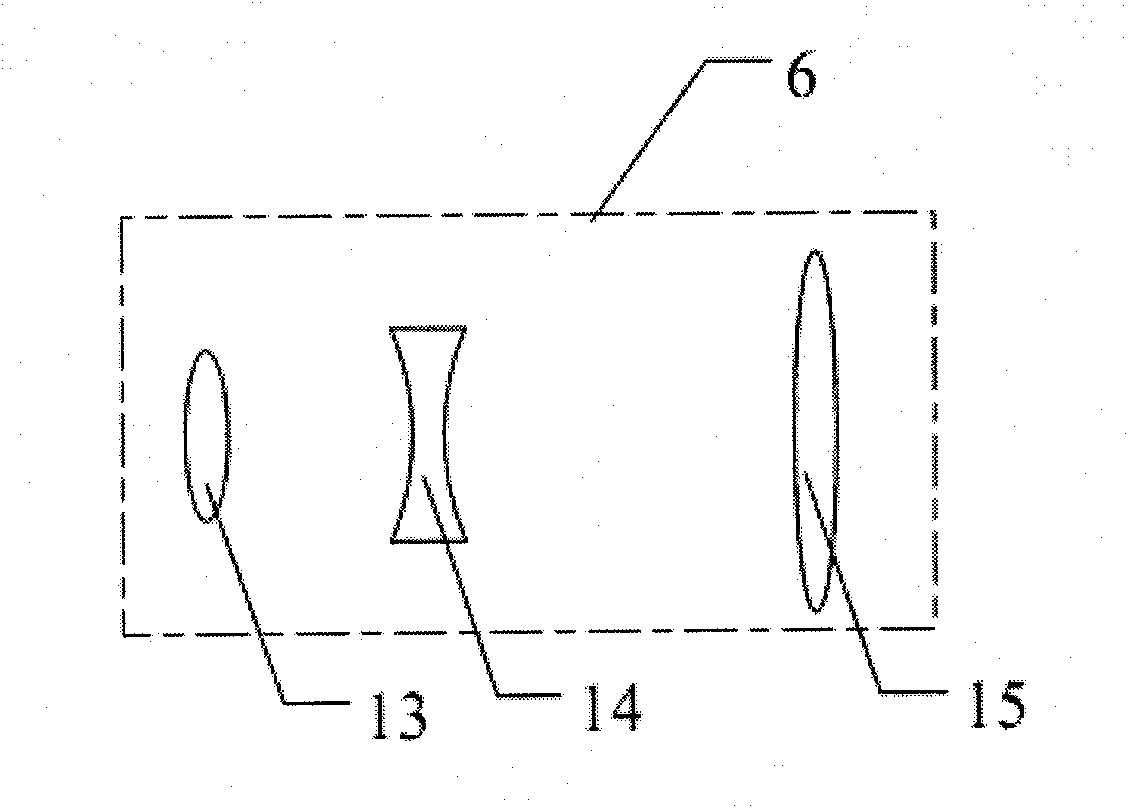

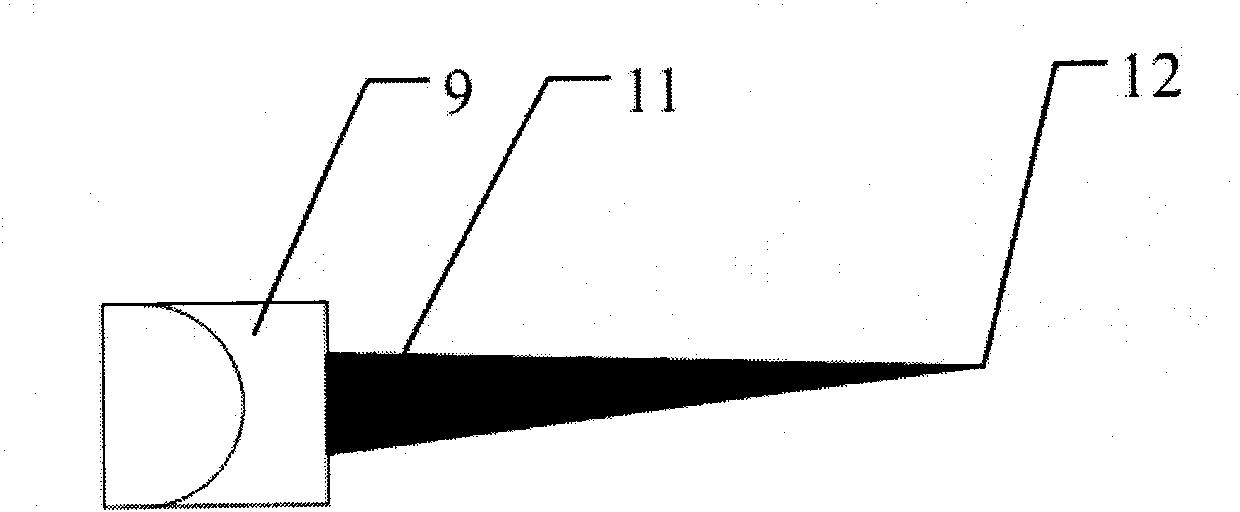

[0016] A linear beam shaping optical system, including a laser source 1, the laser source 1 radiates laser 2, the power of the laser 2 is 30W, the wavelength of the laser 2 is 808nm, the laser 2 is coupled to the optical fiber 4 through the optical fiber coupling system 3, the optical fiber 4 has a core diameter of 200 microns. After the laser 2 is transmitted through the optical fiber 4, it forms a beam 5 with a relatively uniform energy distribution. The beam 5 is incident on the beam focusing system 6. The beam shaping system 7; the linear beam shaping system 7 includes a cylindrical mirror 8 (the focal length of the cylindrical mirror is f=45mm) and an improved Powell prism 9 (the included angle of the roof surface is 70°). After the laser beam 5 passes through the focusing system 6, a converging beam 10 is formed. The converging beam 10 passes through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com