Heat treatment technique of thick-wall aluminum alloy hollow extruded section

A technology for extruded profiles and aluminum alloys, which is applied in the field of heat treatment of Al–Zn–Mg series deformed aluminum alloy extruded profiles, can solve the problems of unsuitable heat treatment for large cross-sections and thick parts, and achieve inhibition of recrystallization and crystal grains Coarse, increase supersaturation, eliminate the effect of tissue internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the components (wt.%) are: Zn3.5~3.8; Mg1.2~1.5; Cu0.08~0.10; Fe0.06~0.10; Si0.10~0.15; Mn0.30~0.35; Cr0. 18~0.22; Zr0.10~0.15; Ti0.04~0.06; V0.01~0.03; the total of other impurity elements≤0.20; the balance is Al, the aluminum alloy hollow extrusion profile for rail transit is heated to 430 ℃ for heat preservation 5h, continue to heat to 480°C for 2h, the heating time is 45min, then take out of the oven, cool to room temperature with strong wind; after artificial aging at 120°C for 40 minutes, cool to room temperature with strong wind; after artificial aging at 65°C for 7 days, take out of the oven and cool in air; Artificial aging at 120°C for 40h, heating time for 1h10min, then out of the oven, natural air cooling. Tensile samples were cut along the extrusion direction of the profile to measure the tensile properties of the alloy at room temperature.

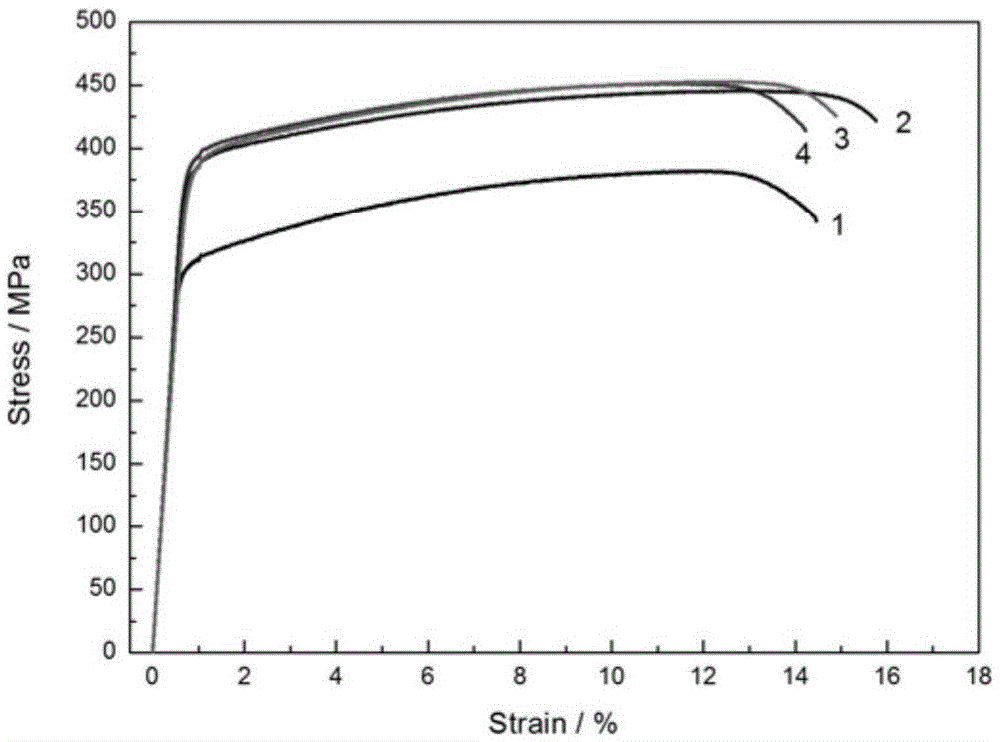

[0061] Such as figure 1 As shown in the 2# curve, the strength of the alloy has increased sign...

Embodiment 2

[0063] In this embodiment, the components (wt.%) are: Zn3.5~3.8; Mg1.2~1.5; Cu0.08~0.10; Fe0.06~0.10; Si0.10~0.15; Mn0.30~0.35; Cr0. 18~0.22; Zr0.10~0.15; Ti0.04~0.06; V0.01~0.03; the total of other impurity elements ≤0.20; the balance is Al aluminum alloy hollow extruded profiles for rail transit, and the temperature is raised to 420 ℃ for heat preservation 5h, continue to heat to 480°C for 2h, the heating time is 50min, then take it out of the furnace, and cool it to room temperature with strong wind; after artificial aging at 115°C for 90 minutes, cool it to room temperature with strong wind; Artificial aging at 115°C for 48 hours, heating time for 1 hour, then out of the oven, and natural air cooling. Tensile samples were cut along the extrusion direction of the profile to measure the tensile properties of the alloy at room temperature.

[0064] Such as figure 1 As shown in the 3# curve, the yield strength of the alloy is 383.0MPa, the tensile strength is 453.0MPa, the e...

Embodiment 3

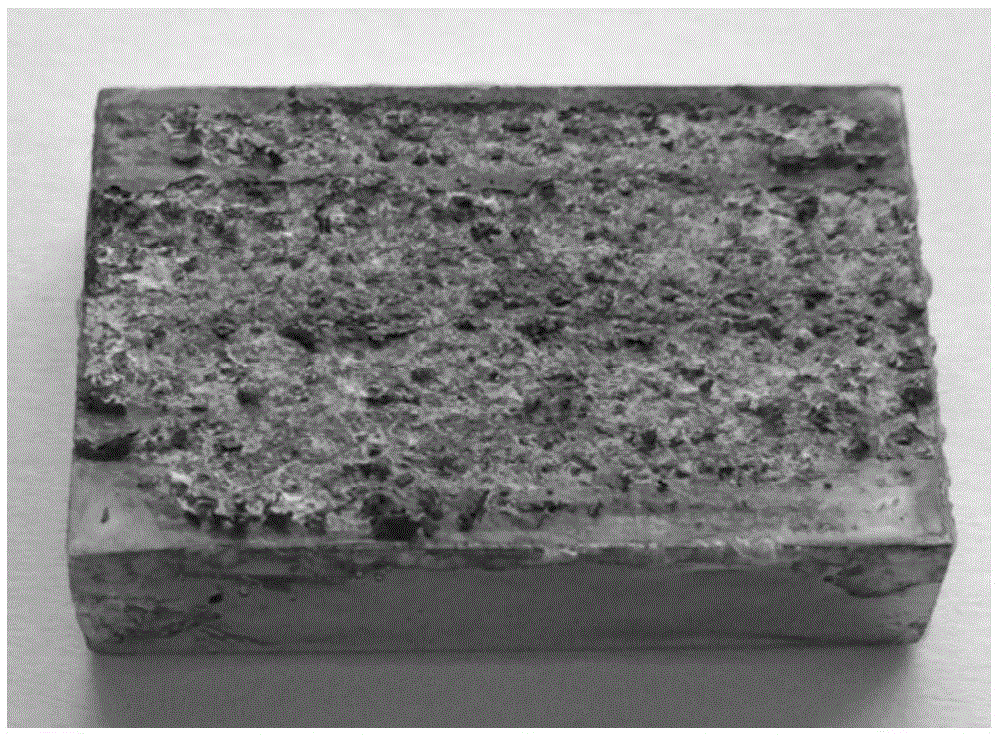

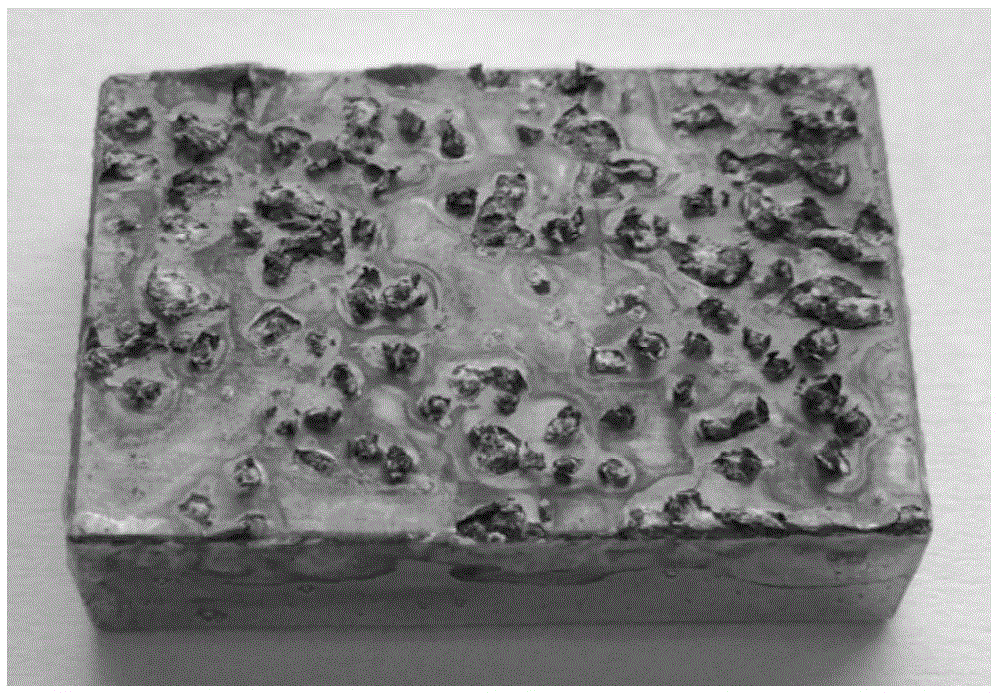

[0066] In this embodiment, the components (wt.%) are: Zn3.5~3.8; Mg1.2~1.5; Cu0.08~0.10; Fe0.06~0.10; Si0.10~0.15; Mn0.30~0.35; Cr0. 18~0.22; Zr0.10~0.15; Ti0.04~0.06; V0.01~0.03; the total of other impurity elements ≤0.20; the balance of aluminum alloy hollow extrusion profiles for rail transit is heated to 400 ℃ for heat preservation 8h, continue to heat up to 490°C for 1.5h, the heating time is 1.5h, then take it out of the oven, and cool it to room temperature with strong wind; after artificial aging at 120°C for 60 minutes, take it out of the oven and cool it to room temperature with strong wind; after artificial aging at 65°C for 10 days, take it out of the oven and cool it in air ; Then artificial aging at 120 ℃ for 42 hours, heating time is 1h15min, then out of the oven, natural air cooling. Tensile samples were cut along the extrusion direction of the profile, and the tensile properties of the alloy at room temperature were measured, and the exfoliation corrosion test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com