Heat treatment method of single crystal nickel-based superalloy after cold deformation

A technology of nickel-based superalloy and heat treatment method, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., and can solve problems such as heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

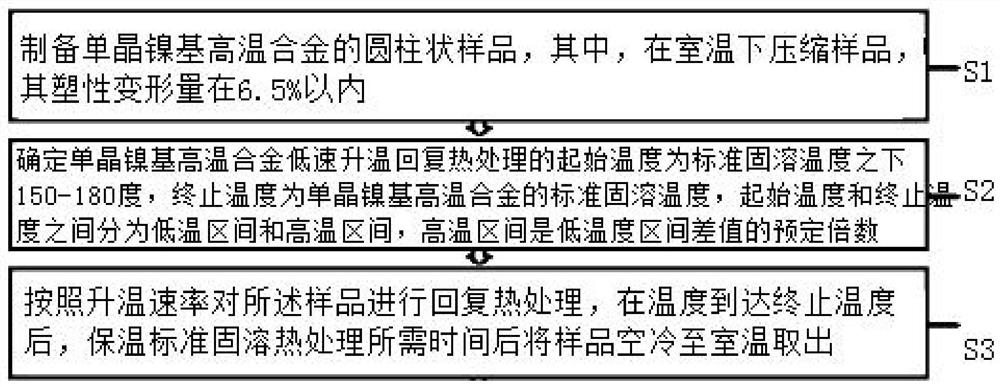

[0037] Step 1: Prepare a standard cylindrical sample with an aspect ratio of 2:1. The deformation mode is compression at room temperature, and the plastic deformation of the sample is 6.5%;

[0038]Step 2: Determine that the temperature below the standard solution temperature of the single crystal nickel-based superalloy is 150°C as the low-speed heating recovery heat treatment starting temperature of 1150°C, and the termination temperature is the standard solution temperature of the single crystal nickel-based superalloy of 1300°C;

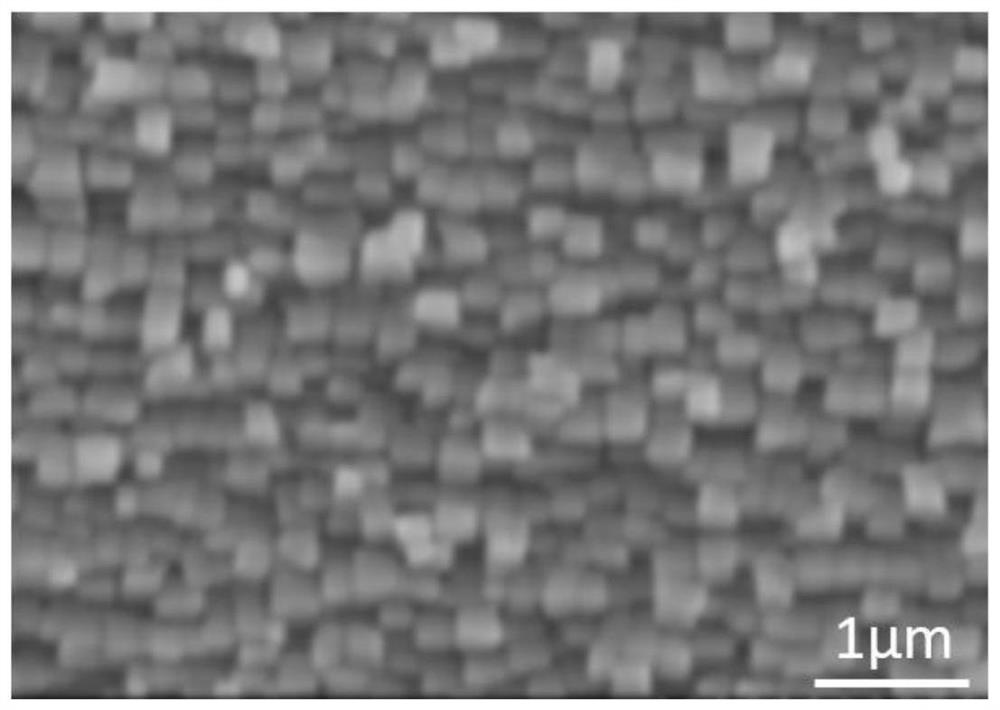

[0039] Step 3: The heating rate is determined by different temperature zones. Between the start temperature and the end temperature, it is divided into a low temperature range and a high temperature range. According to the high temperature range is 0.618 times the temperature difference (golden section point) of the low temperature range, the low temperature range is 1150-1243 ° C, and the heating rate is 0.15 ° C / min, the high temperature rang...

Embodiment 2

[0044] Step 1: Prepare a standard cylindrical sample with an aspect ratio of 2:1. The deformation mode is compression at room temperature, and the plastic deformation of the sample is 6.5%;

[0045] Step 2: Determine that the temperature below the standard solution temperature of the single crystal nickel-based superalloy is 180°C as the low-speed heating recovery heat treatment starting temperature of 1120°C, and the end temperature is the standard solution temperature of the single crystal nickel-based superalloy of 1300°C;

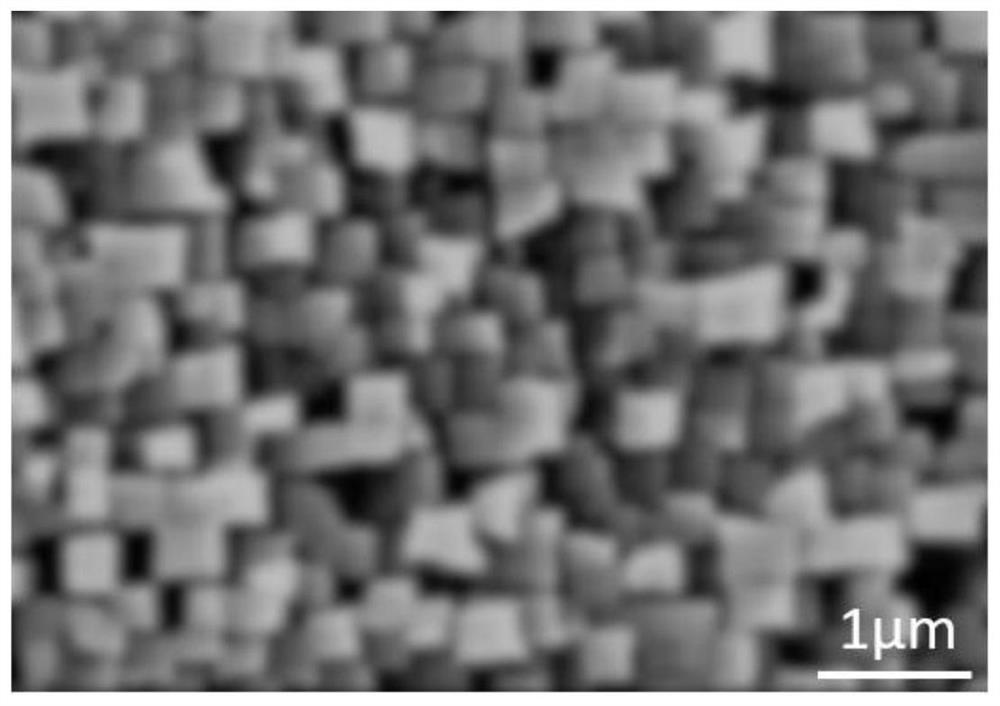

[0046] Step 3: The heating rate is determined by different temperature zones. Between the start temperature and the end temperature, it is divided into a low temperature range and a high temperature range. According to the high temperature range is 0.618 times the temperature difference (golden section point) of the low temperature range, the low temperature range is 1120-1230 ° C, and the heating rate is 0.5 ° C / min, the high temperature range is 123...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com