Annealing heat treatment method for eliminating residual stress of HastelloyC-276 thin-wall spinning shielding sleeve

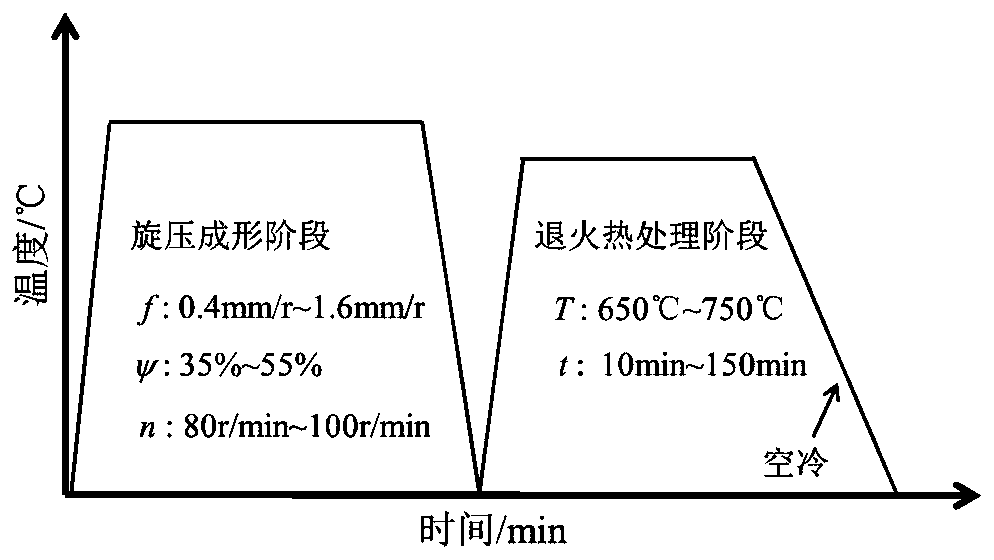

An annealing heat treatment and residual stress technology, applied in heat treatment furnaces, heat treatment equipment, process efficiency improvement, etc., can solve the problems that no scholars have proposed to reduce the residual stress of Hastelloy C-276 thin-walled spinning shielding sleeve, so as to reduce residual stress, The effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

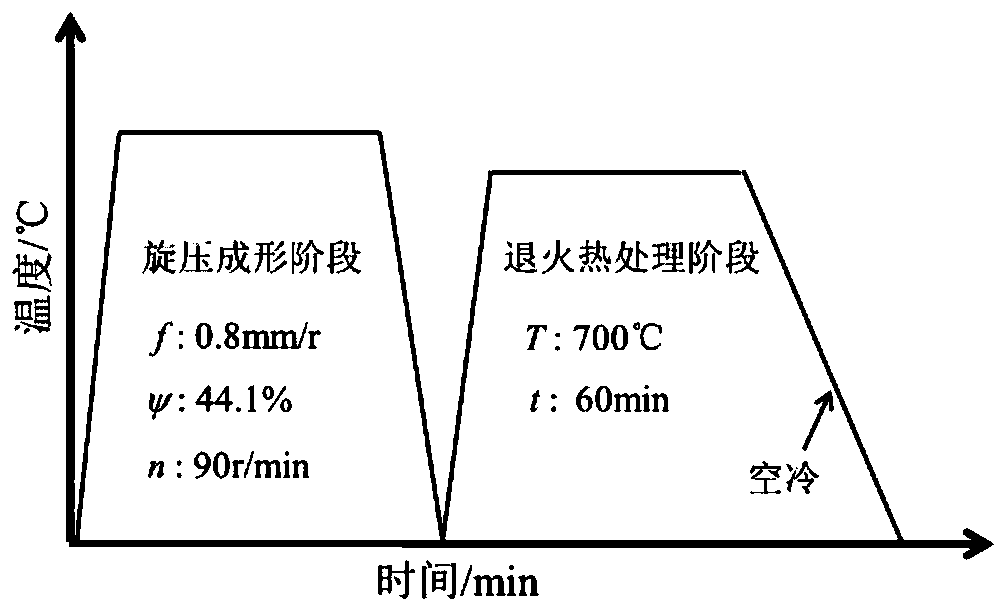

Embodiment 1

[0018] Step 1: Carry out spin forming on Hastelloy C-276 thin-walled shielding sleeve blank, the process parameters of spinning forming are: feed ratio 0.8mm / r, thinning rate 44.1%, mandrel speed 90r / min;

[0019] Step 2: Perform annealing heat treatment on the shielding sleeve after spinning, the annealing temperature is 700°C, and the holding time is 60 minutes;

[0020] Step 3: After the annealing heat treatment is completed, immediately take out the shielding sleeve and air cool to room temperature. The schematic diagram of the process flow of Example 1 is as follows: figure 2 shown.

[0021] The residual stress of the thin-walled shielding sleeve after spinning and annealing heat treatment was measured, and the results are shown in Table 1. In order to prove the feasibility of the method of the present invention, the measured value of the residual stress of the shielding sleeve after spinning and Example 1 is compared in Table 1. It can be seen that in Example 1, the th...

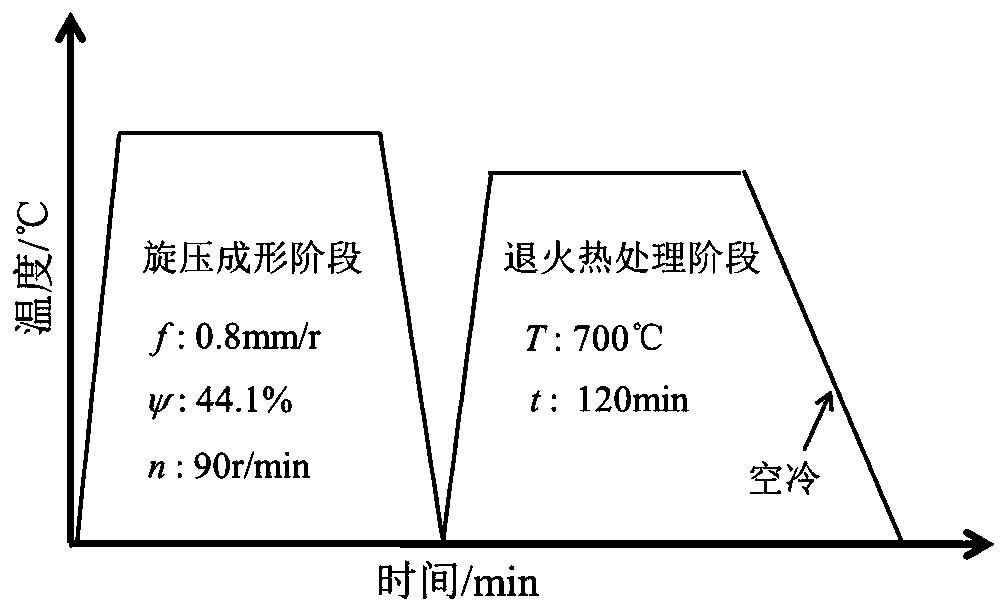

Embodiment 2

[0023] Step 1: Carry out spin forming on Hastelloy C-276 thin-walled shielding sleeve blank, the process parameters of spinning forming are: feed ratio 0.8mm / r, thinning rate 44.1%, mandrel speed 90r / min;

[0024] Step 2: Perform annealing heat treatment on the shielding sleeve after spinning, the annealing temperature is 700°C, and the holding time is 120 minutes;

[0025] Step 3: After the annealing heat treatment is completed, immediately take out the shielding sleeve and air-cool to room temperature. The schematic diagram of the process flow of Example 2 is as follows image 3 shown.

[0026] The residual stress of the thin-walled shielding sleeve after spinning and annealing heat treatment was measured, and the results are shown in Table 1. In order to prove the feasibility of the method of the present invention, comparing the measured values of the residual stress of the shielding sleeve after spinning in Table 1 with that of Example 2, it can be seen that in Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com