Lithium ion battery separator, preparation method thereof and lithium ion battery

A technology for lithium ion batteries and separators, applied in the field of lithium ion battery separators and their preparation, can solve problems such as damage to the separators, and achieve the effects of reducing thermal shrinkage rate, reducing capacity decay, and being difficult to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] According to a second aspect of the present invention, a kind of preparation method of lithium-ion battery separator is provided, comprising the following steps:

[0072] Uniformly coat the cyclodextrin polymer slurry on the PP / PE / PP porous film substrate to form a cyclodextrin polymer layer, and obtain a lithium-ion battery separator after drying;

[0073] The cyclodextrin polymer slurry includes cyclodextrin polymer and water.

[0074] The cyclodextrin polymer slurry is obtained by dissolving or dispersing the cyclodextrin cross-linked polymer in water, and can form a gel state fluid. The viscosity of the cyclodextrin polymer slurry is preferably 50-500mPa·s, such as 50mPa·s s, 100mPa·s, 120mPa·s, 150mPa·s, 200mPa·s, 300mPa·s, 400mPa·s or 500mPa·s.

[0075] The cyclodextrin polymer is preferably a cyclodextrin cross-linked polymer, which is obtained after the main cyclodextrin is cross-linked by an appropriate cross-linking agent. The source of the cyclodextrin cross...

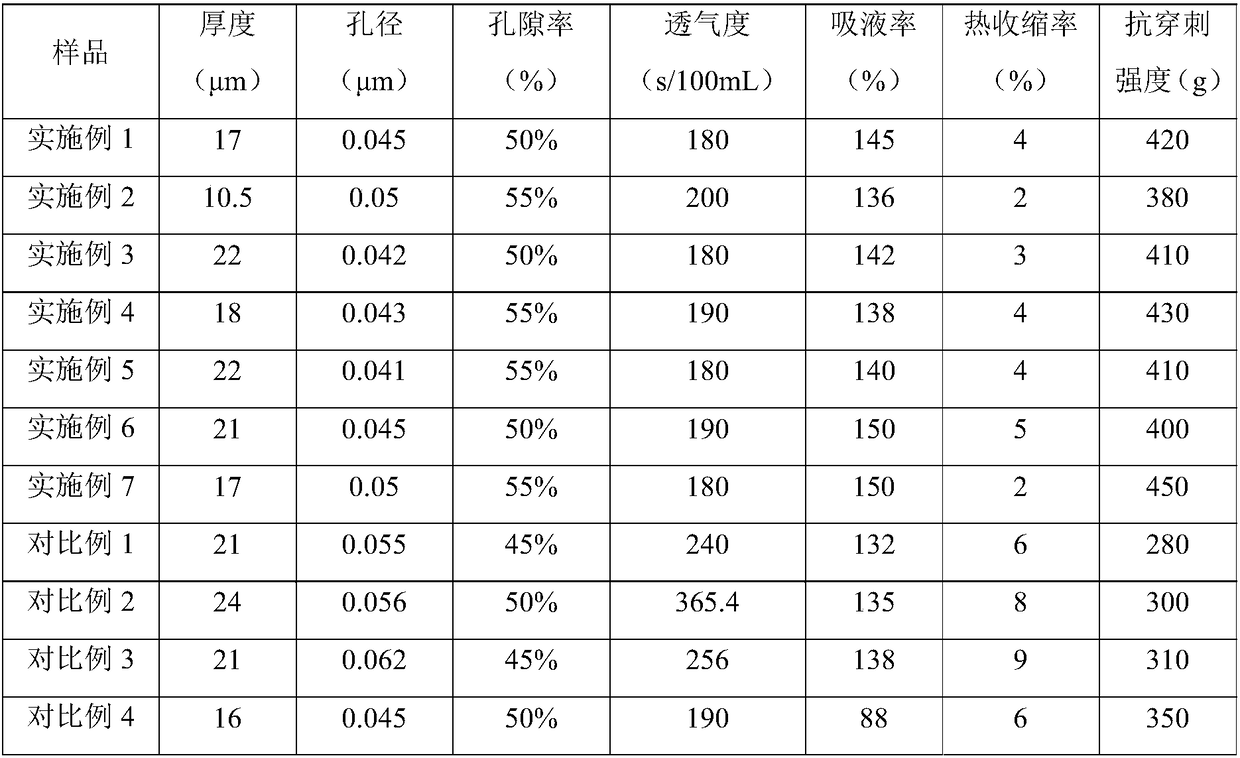

Embodiment 1

[0102] A lithium ion battery separator, comprising a Celguard 16 μm separator substrate and a cyclodextrin polymer layer on the surface of the Celguard 16 μm separator substrate, the thickness of the cyclodextrin polymer layer being 1 μm.

[0103] A preparation method for a lithium-ion battery diaphragm, comprising the following steps:

[0104] (1) 0.5 parts by weight of binder, 3 parts by weight of water-based dispersant and 0.1 parts by weight of surfactant are dissolved in 50 parts by weight of water to obtain solution A;

[0105] (2) Dissolving 25 parts by weight of cyclodextrin polymer in the remaining 50 parts by weight of water to obtain solution B;

[0106] (3) Mix solution A and solution B uniformly to obtain cyclodextrin polymer slurry;

[0107] (4) The cyclodextrin polymer slurry was uniformly coated on one side of the Celguard 16 μm separator substrate, and dried to obtain a lithium ion battery separator coated with a cyclodextrin polymer layer.

Embodiment 2

[0109] A lithium ion battery separator, comprising a Celguard 10 μm separator substrate and a cyclodextrin polymer layer on the surface of the Celguard 10 μm separator substrate, the thickness of the cyclodextrin polymer layer being 0.5 μm.

[0110] A preparation method for a lithium-ion battery diaphragm, comprising the following steps:

[0111] (1) 2 parts by weight of binder, 0.1 parts by weight of water-based dispersant and 2 parts by weight of surfactant are dissolved in 30 parts by weight of water to obtain solution A;

[0112] (2) Dissolving 10 parts by weight of cyclodextrin polymer in the remaining 30 parts by weight of water to obtain solution B;

[0113] (3) Mix solution A and solution B uniformly to obtain cyclodextrin polymer slurry;

[0114] (4) The cyclodextrin polymer slurry is evenly coated on one side of the Celguard 10 μm separator substrate, and dried to obtain a lithium ion battery separator coated with a cyclodextrin polymer layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com