Optical film with sharpened bandedge

A thin-film body and optical thickness technology, applied in optics, optical components, instruments, etc., can solve the problems of not being able to improve the steepness and variation of the band edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1 - Inverting the Gradient

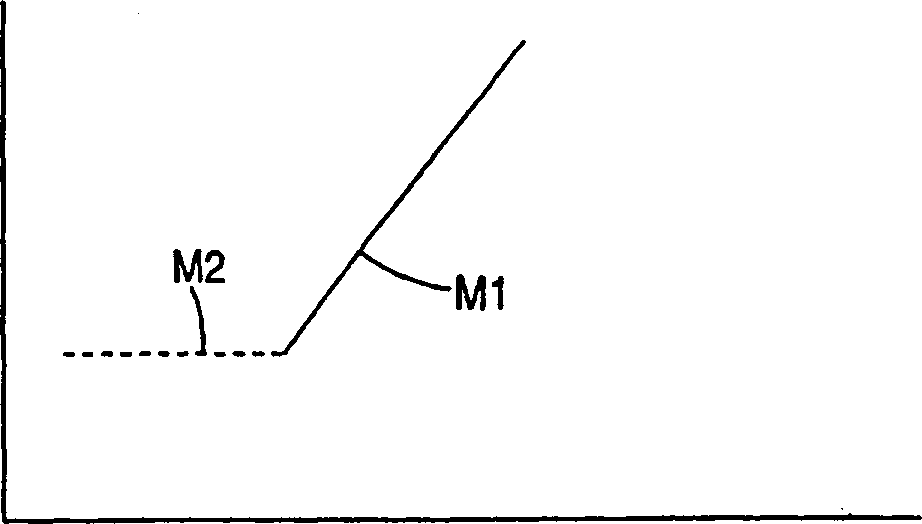

[0083] Figure E1a Shown is an example of inverting the gradient. The figure shows the bound layer thickness gradient of LTG1 and LTG2. In this case, the band-edge-steep gradient, LTG2, consists of 20 layers of alternating high- and low-index materials, the thickness of both materials increasing to maintain a 0.5 Å from the first to the last layer. f-ratio.

[0084] Another example of inverting the gradient is shown in Figure E1b . The figure shows the short-wavelength bandedge of the reflection band caused by the layer thickness gradient LTG1, and the effect of adding the inversion gradient LTG2. Adding LTG2 results in an increase in edge slope. The band edge slope without LTG2 was 1.1% / nm. When LTG2 was added, the slope increased to 1.9% / nm. The layer thickness distribution diagram is shown in Figure E1a .

Embodiment 2

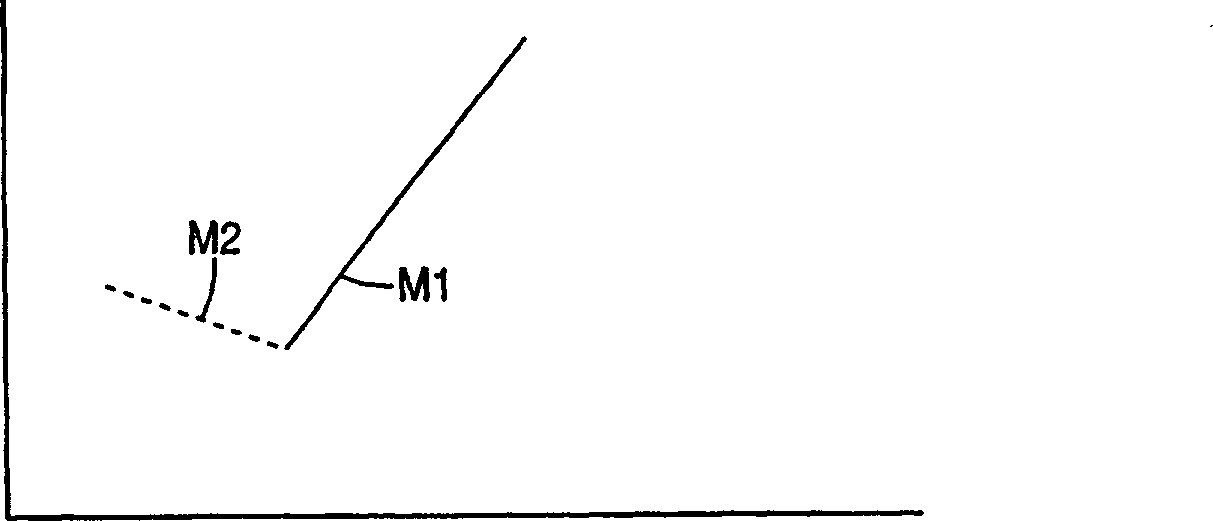

[0085] Example 2 - Inverted gradient with f-ratio bias

[0086] Figure E2a Shown is an example of a stack design with an f-ratio bias reversal gradient. The figure shows a thin-film stack design with only one material component having an inversion gradient and the other material component having zero gradient in the added band-edge-steepening LTG3 stack. This combination of LTG1 and LTG3 also shows improved band edge sharpness compared to LTG1, as follows Figure E2b shown. The band edge slope with LTG3 added was 7.3% / nm.

Embodiment 3

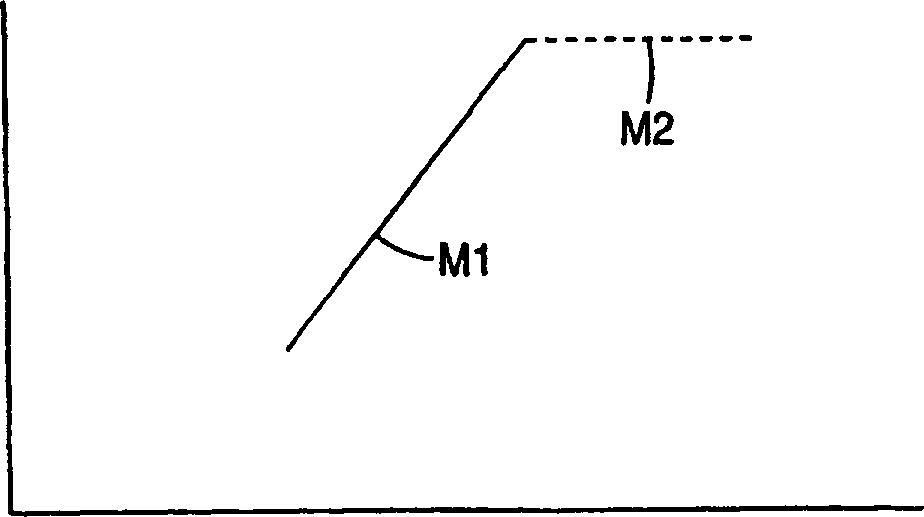

[0087] Example 3 - Zero Gradient

[0088] This example shows the band edge steepening effect of a zero gradient stack LTG4 of two materials. The stack design of this example also produces a much steeper band edge than LTG1 alone. The band edge slope in this case was 3.6% / nm.

[0089] Figure E3a The layer thickness gradient for the combination of laminates LTG1 and LTG4 is shown. Both materials in LTG4 have zero thickness gradient and maintain a constant thickness ratio between the high and low refractive index layers. Such as Figure E3b As shown, a significant improvement was observed compared to the case of LTG1. The band edge slope is 3.6% / nm compared to the 1.1% / nm value for LTG1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com