Non-contact type measurement indirect tensile strain method

A tensile strain, non-contact technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of low accuracy of measurement methods, limited measurement area, small measurement range, etc., to achieve easy operation, simple steps, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

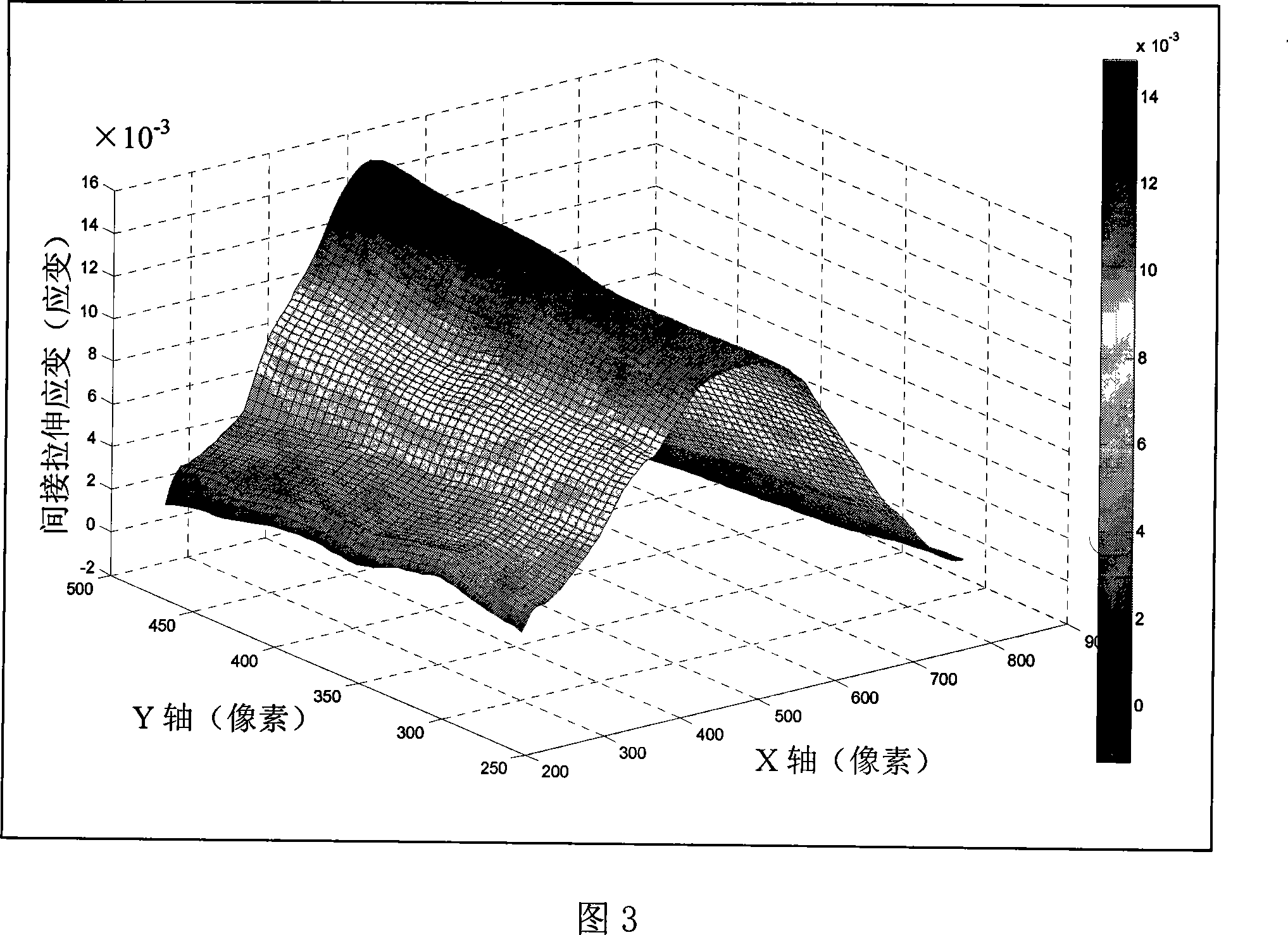

[0030] The specific process of the method for non-contact measurement of indirect tensile strain in this embodiment is:

[0031] Step 1, prepare Marshall test piece;

[0032] Step 2, cutting the prepared Marshall test piece to a height of 63.5±1.3mm;

[0033] Step 3, performing artificial spotting on the cut end face of the test piece obtained in step 2, and then drying;

[0034] Step 4, fixing the test piece obtained in step 3 in the fixture of the mechanical loading instrument;

[0035] Step 5. Fix and place the lens of the CCD camera relative to the end face of the artificial speckled specimen;

[0036] Step 6, fixing a measuring light source between the end face of the artificially speckled test piece and the CCD camera, the measuring light source makes the light on the end face of the artificially speckled test piece uniform;

[0037] Step 7. Adjust the CCD camera so that the optical axis of the CCD camera is perpendicular to the end face of the artificially speckled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com