Manufacture of tubular targets

A manufacturing method and tube target technology, applied in the direction of manufacturing tools, casting workshops, casting equipment, etc., can solve problems affecting stoichiometric adjustment, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

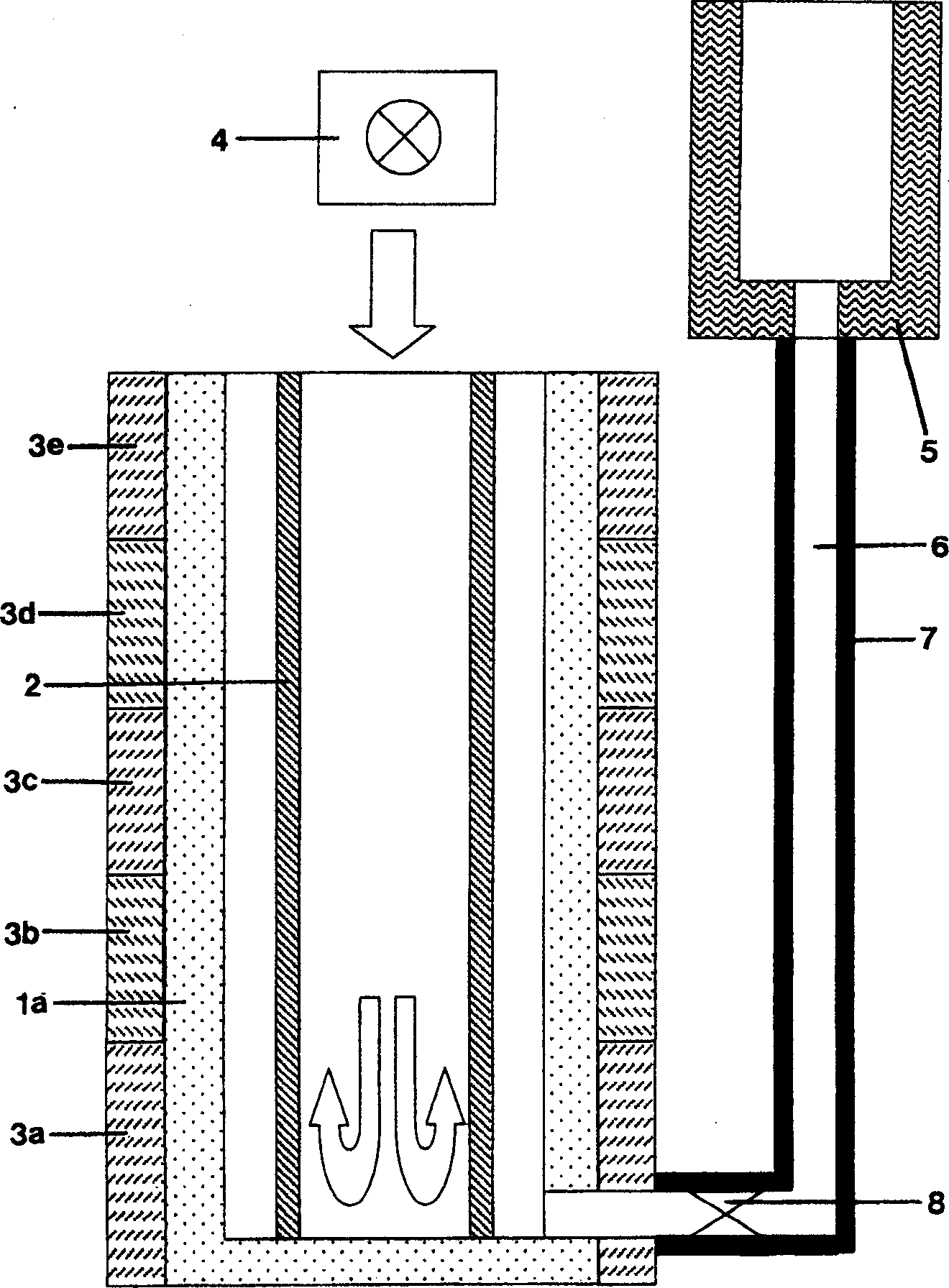

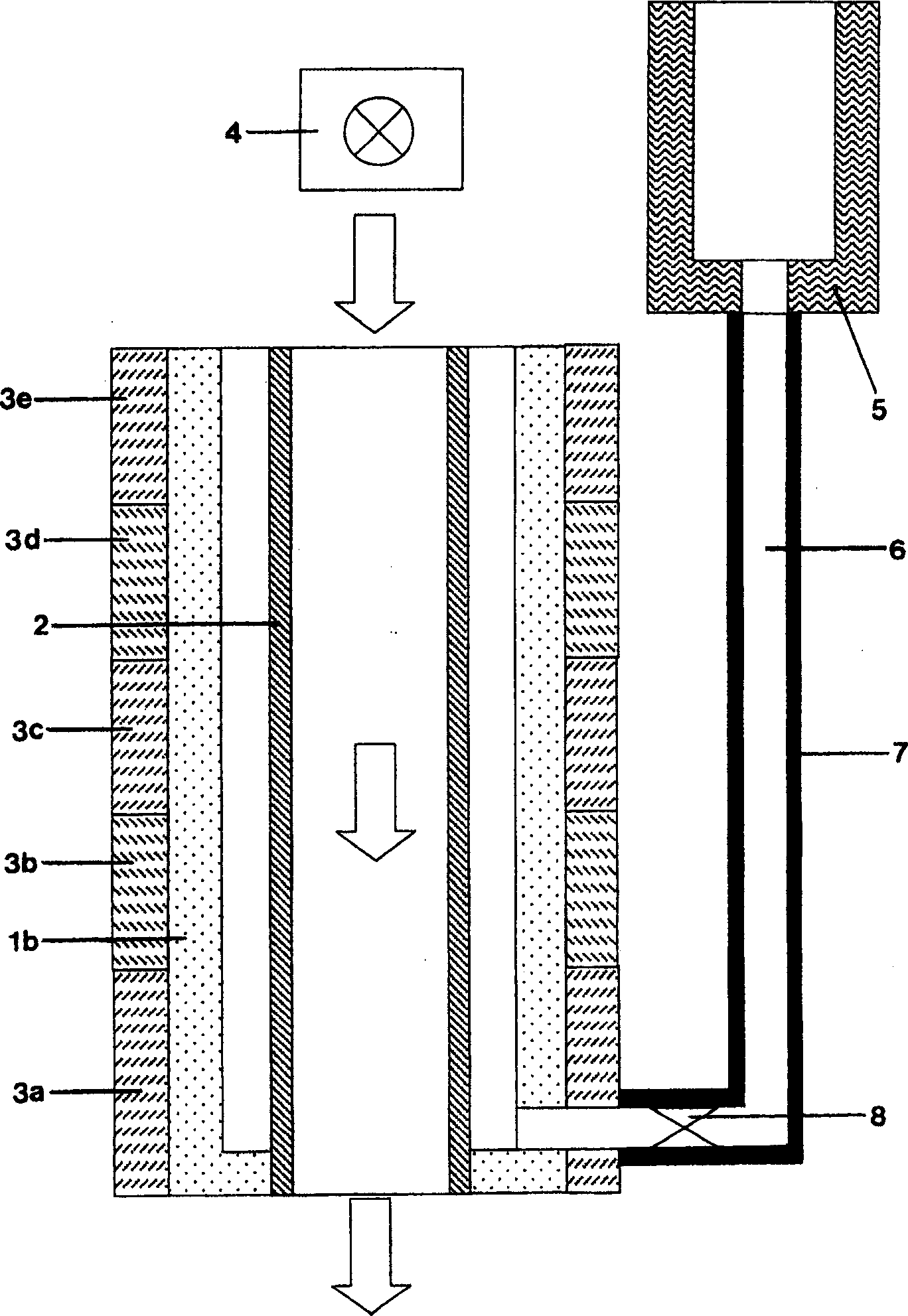

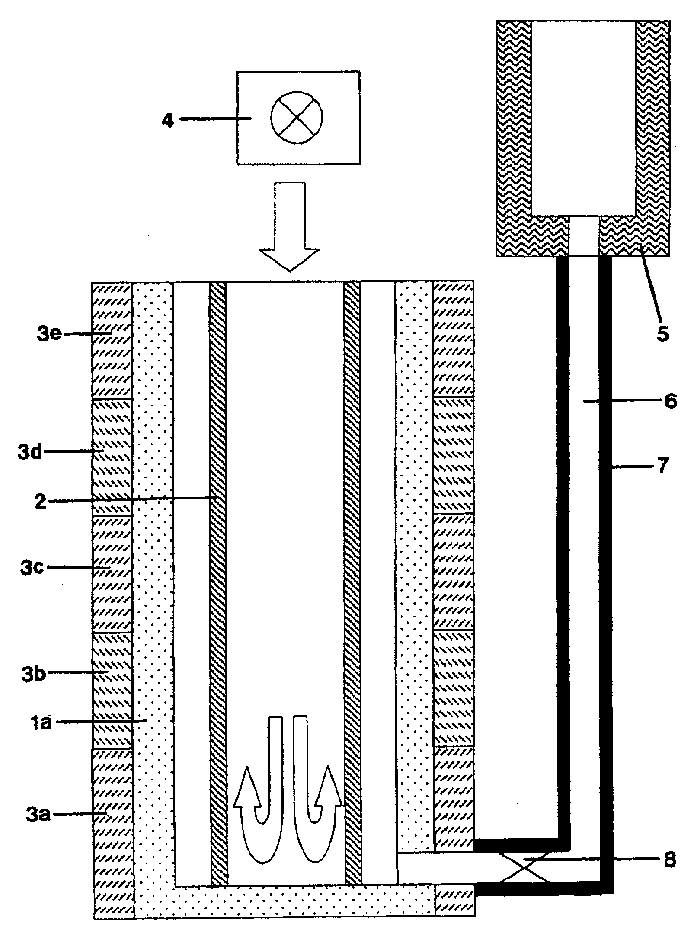

[0034] An inner tube (inner diameter 127 mm, outer diameter 133 mm, length 1500 mm) made of high-quality steel was welded to its outer diameter with a commercially available flux with tin. The welded inner tube is placed in the center of the mold halves. The casting mold is heated from the outside to approximately 300° C. by heating mats, and the inner tube is likewise heated to approximately 300° C. on its inner diameter by means of a hot air blower. In a through a siphon (see figure 1 ) in the melting crucible communicated with the casting mold with the protection of argon atmosphere to melt the tin with a purity of 99.99%. The molten tin flows into the mold through a heated pipe and fills the cavity between the inner tube and the mold until it reaches the upper edge of the mold. Then stop the hot air blower and stop heating and remove the heating pads that are arranged sequentially from the bottom of the mold. At the upper end of the mold, the metal liquid level is preve...

example 2

[0037]An inner tube (inner diameter 127 mm, outer diameter 133 mm, length 1500 mm) made of high-quality steel was welded to its outer diameter with a commercially available flux with zinc. The welded inner tube is placed in the center of the mold halves. The casting mold is heated from the outside to 500° C. by heating mats, and the inner tube is likewise heated to approximately 500° C. on its inner diameter by means of a hot air blower. In a through a siphon (see figure 1 ) protect and melt zinc with an argon atmosphere in a melting crucible communicated with the mold. Molten zinc flows into the mold through a heated pipe and fills the cavity between the inner tube and the mold until it reaches the upper edge of the mold. Then stop the hot inner blower and stop the heating and remove the heating pads arranged sequentially from the bottom of the mold. At the upper end of the mold, the molten zinc is replenished to prevent the metal liquid level from falling. After the zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com