Power module metalized ceramic substrate and metallization method thereof

A technology for metallizing ceramics and ceramic substrates, applied in chemical instruments and methods, metal layered products, ceramic layered products, etc., can solve the problems of poor bonding strength, unsatisfactory solderability, rough surface, etc. The effect of strong heat dissipation, improved antioxidant capacity, and optimized function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

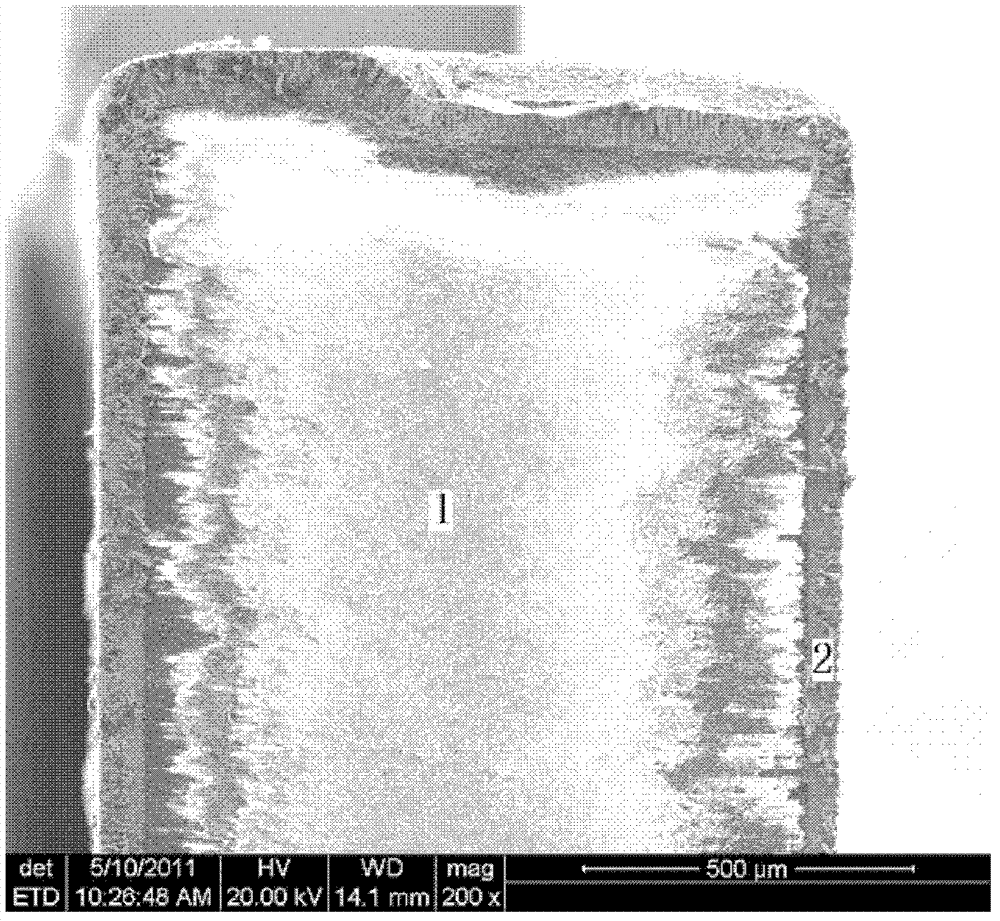

[0036] Embodiment 1: AlN substrate metallization

[0037] Select an AlN substrate with a size of 43×23×1mm, which is chemically roughened (by 40% HF 80ml / L+NH 4 F 30g / L with roughening solution), ultrasonically cleaned with absolute ethanol, dried, and then suspended in the vacuum chamber of the arc ion plating device facing the Cu target. Evacuate the vacuum chamber to 3 x 10 -3 After Pa, turn on the sample heating system and set the temperature to 300 °C. Introduce argon and maintain the vacuum chamber gas pressure at 2.0Pa. Start the hanger and make the AlN substrate rotate. Under the condition of negative bias voltage -800V (duty cycle adjusted to 0), the AlN substrate was glow-cleaned for 5 minutes; after that, the flow rate of argon gas was adjusted to a pressure of 0.6Pa in the vacuum chamber, and the Cu target power was turned on, and the control current was 70A ( The corresponding voltage is 21V), and continue ion bombardment (arc cleaning) on the AlN substrate ...

Embodiment 2

[0039] Example 2: Al 2 o 3 Substrate metallization

[0040] Select Al with dimensions 50×30×6mm 2 o 3 The substrate is suspended in the vacuum chamber of the magnetron sputtering device facing the Cu target after polishing, degreasing, ultrasonic cleaning with absolute ethanol, and drying. The vacuum chamber is evacuated to 2×10 -3 After Pa, turn on the sample heating system and set the temperature to 300 °C. Introduce argon and maintain the vacuum chamber gas pressure at 2.0Pa. The negative electrode of the power supply is connected to the Cu target and grounded, and the positive electrode is connected to the vacuum chamber shell and the device suspension frame. Select an intermediate frequency power supply with a frequency of 20KHz, a current of 2A, and a voltage of 300V, start the hanger to rotate the substrate, and glow-clean the substrate for 5 minutes. The pressure of the vacuum chamber was adjusted to 0.3 Pa, and then the current was adjusted to 3.5 A, the voltag...

Embodiment 3

[0042] Example 3 SiC substrate metallization

[0043] Select a SiC substrate with a size of 33×20×3mm, and hang it facing the Ag target in the vacuum chamber of the arc ion plating device after surface polishing, degreasing, ultrasonic cleaning with absolute ethanol, and drying. Evacuate the vacuum chamber to 3 x 10 -3 After Pa, turn on the sample heating system and set the temperature to 350 °C. Introduce argon and maintain the vacuum chamber gas pressure at 2.0Pa. Start the hanger and make the SiC substrate rotate. The substrate was glow-cleaned for 5 minutes under the condition of negative bias voltage -800V (duty cycle adjusted to 0); after that, adjust the argon gas flow rate to the pressure of 0.6Pa in the vacuum chamber, turn on the power supply of the Ag target, and control the current to 65A (corresponding to The voltage is 21.5V), and the SiC substrate is continuously bombarded with ions (arc cleaning) for 5 minutes. Adjust the bias voltage to -400V (adjust the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com