Fluorinated zirconium-manganese-sodium phosphate/carbon composite material, positive electrode material, positive electrode, sodium ion battery and preparation method of fluorinated zirconium-manganese-sodium phosphate/carbon composite material

A technology of fluorinated sodium zirconium manganese phosphate and sodium zirconium manganese phosphate, applied in the field of sodium ion battery materials, can solve the problem of electrode material specific capacity, kinetic performance and cycle performance deterioration, technology maturity lag, intercalation and diffusion difficulties and other problems, to achieve the effect of being conducive to rapid migration, improved electrical properties, and excellent electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

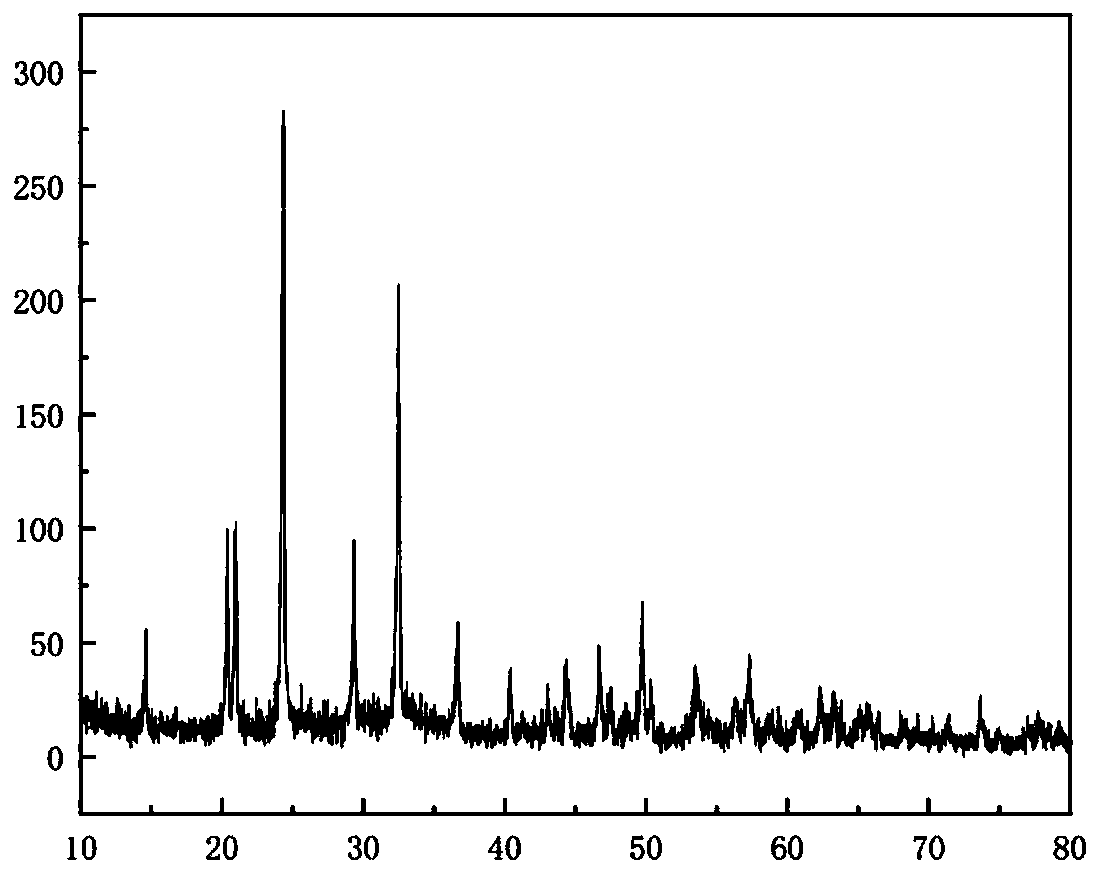

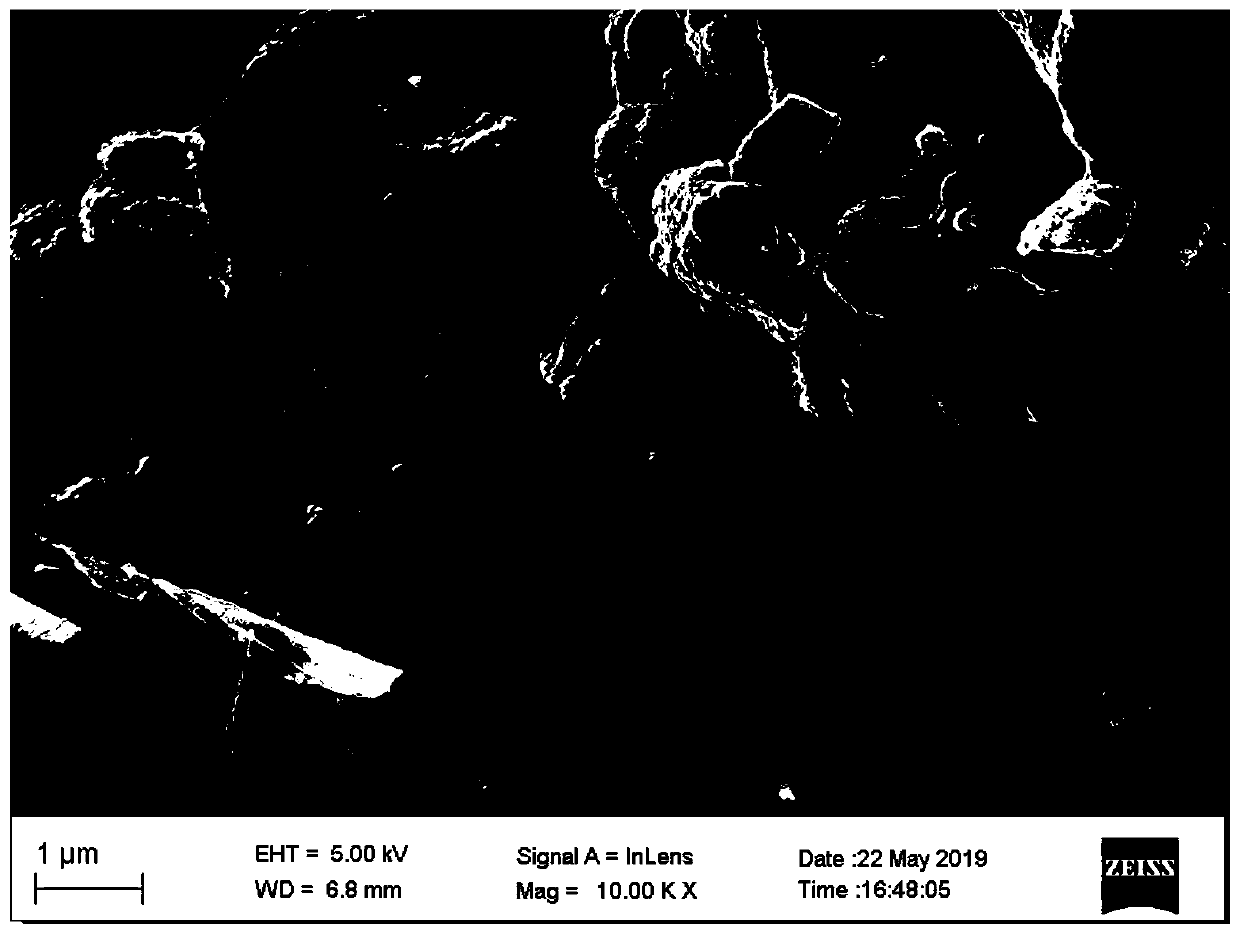

[0071] Dissolve 0.01mol of zirconium oxynitrate, 0.01mol of manganese acetate, 0.02mol of ammonium dihydrogen phosphate in deionized water, stir and evaporate at 80 degrees to form a gel, and place the gel in a vacuum drying oven at 80 degrees to dry 4h, and then put it into a tube furnace with argon gas, and sintered at 750 degrees for 10h. The intermediate zirconium manganese phosphate is obtained, the zirconium manganese phosphate intermediate and sodium fluoride are mixed in a molar ratio of 1:3, and 0.03 mol of citric acid is added. 500r / min ball milling for 8h, sintering at 700 degrees under argon for 12h. Get Na 3 ZrMn(PO 4 ) 2 F 3 / C, xrd such as figure 1 , sem, figure 2 .

[0072] Using the prepared Na 3 ZrMn(PO 4 ) 2 F 3 / C composite material, assembled into a sodium ion button battery, the measured electrochemical data are as follows, the average voltage is 4.0V, after 100 cycles at 0.5C, the discharge specific capacity reaches 90.5mAh / g, and the capacit...

Embodiment 2

[0074] Dissolve 0.01mol of zirconium oxynitrate, 0.01mol of manganese acetate, 0.02mol of ammonium dihydrogen phosphate in deionized water, stir and evaporate at 80 degrees to form a gel, and place the gel in a vacuum drying oven at 80 degrees to dry 4h, and then put it into a tube furnace with argon gas, and sintered at 650 degrees for 8h. The intermediate manganese zirconium phosphate is obtained, the intermediate manganese zirconium phosphate and sodium fluoride are mixed in a molar ratio of 1:3, and 0.03 mol of citric acid is added. 500r / min ball milling for 8h, sintering at 700 degrees under argon for 12h. Get Na 3 ZrMn(PO 4 ) 2 F 3 / C.

[0075] Using the prepared Na 3 ZrMn(PO 4 ) 2 F 3 / C composite material, assembled into a sodium ion button battery, the measured electrochemical data are as follows, the average voltage is 4.0V, after 100 cycles at 0.5C, the discharge specific capacity reaches 87.5mAh / g, and the capacity retention rate reaches more than 90% . ...

Embodiment 3

[0077] Dissolve 0.01mol of zirconium oxynitrate, 0.01mol of manganese acetate, 0.02mol of ammonium dihydrogen phosphate in deionized water, stir and evaporate at 80 degrees to form a gel, and place the gel in a vacuum drying oven at 80 degrees to dry 4h, and then put it into a tube furnace with argon gas, and sintered at 850 degrees for 16h. The intermediate manganese zirconium phosphate is obtained, the intermediate manganese zirconium phosphate and sodium fluoride are mixed in a molar ratio of 1:3, and 0.03 mol of citric acid is added. 500r / min ball milling for 8h, sintering at 700 degrees under argon for 12h. Get Na 3 ZrMn(PO 4 ) 2 F 3 / C.

[0078] Using the prepared Na 3 ZrMn(PO 4 ) 2 F 3 / C composite material, assembled into a sodium-ion button battery, the measured electrochemical data are as follows, the average voltage is 4.0V, after 100 cycles at 0.5C, the discharge specific capacity reaches 84.5mAh / g, and the capacity retention rate reaches more than 90% . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com