Preparation method of methyl propionate

A technology of methyl propionate and propionic acid, applied in the field of preparation of methyl propionate, can solve the problems of not achieving ideal results, serious equipment corrosion, great environmental protection pressure, etc. less block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

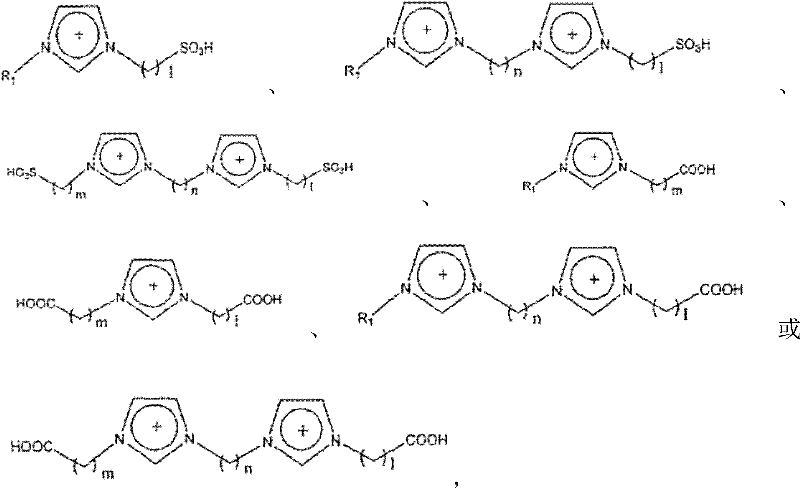

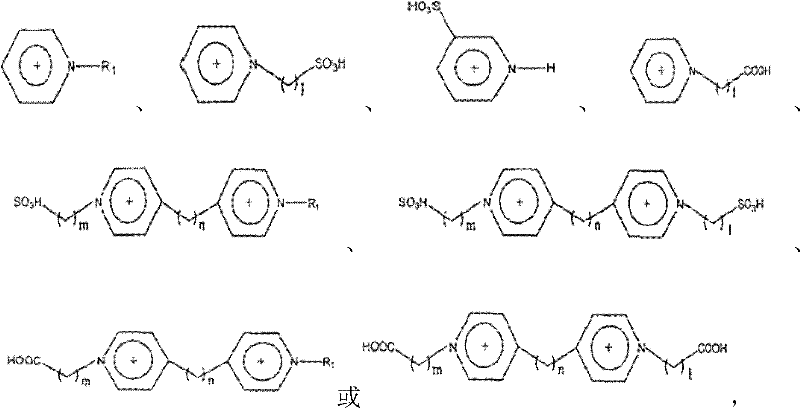

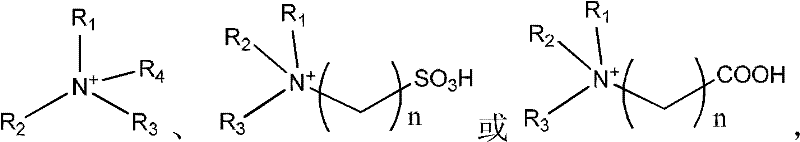

Method used

Image

Examples

Embodiment 1

[0045] In a 500ml reactor, add 200g of propionic acid and 6g of catalyst a, then start heating, and continuously add a mixture of propionic acid and methanol to the reactor at a speed of 0.8mL / min, wherein the molar ratio of propionic acid to methanol It is 6:5. In this reaction rectification process, the reaction kettle is also a rectification tower tower tank at the same time. Two glass packing rectification columns are used to form a rectification tower. The number of theoretical plates is 16. The reflux ratio controller is used to adjust the reflux ratio R=3. Start the reactive distillation process. During this process, an azeotrope of methanol, water and the product methyl propionate was distilled overhead. The temperature in the kettle is 106-108°C, the temperature at the top of the tower is 71-74°C, and the material is discharged continuously for 120 hours. During the reactive distillation process, the components of the distillate remain stable. Chromatographic analys...

Embodiment 2

[0047] Add 180g propionic acid, 4g catalyst b in the reactor, all the other reaction conditions are with embodiment 1. The temperature in the kettle is 107-109°C, the temperature at the top of the tower is 73-76°C, and the material is discharged continuously for 160 hours. During the reactive distillation process, the components of the distillate remain stable. Chromatographic analysis determined that the content of methyl propionate in the reaction distillate was 90.26wt%, the content of methanol was 3.46wt%, and no propionic acid was detected; the water content was 6.28wt% as detected by coulometric titration. After the reaction finished, according to the weight and concentration of the weight of the reactant and the product, the yield of the available product methyl propionate was calculated to be 97.48%.

Embodiment 3

[0049] Add 150g propionic acid, 18g catalyst b in the reactor, form the rectification column with 3 glass packing rectification columns, the number of theoretical plates is 24, all the other reaction conditions are the same as embodiment 1. The temperature in the kettle is 108-110°C, the temperature at the top of the tower is 74-76°C, and the material is discharged continuously for 240 hours. The distillate components remain stable during the reactive distillation process. Chromatographic analysis determined that the content of methyl propionate in the reaction distillate was 92.38wt%, the content of methanol was 2.92wt%, and no propionic acid was detected; the water content was 4.70wt% as detected by coulometric titration. After the reaction, according to the weight of the reactant and the weight and concentration of the product, the yield of the available product methyl propionate is 99.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com