Method for producing 1-propylene glycol with 3-hydracrylic acid methyl ester

A technology of methyl hydroxypropionate and propylene glycol, which is applied in the preparation of oxygen-containing compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low product yield, impact on application, harsh catalyst preparation, etc., and achieve catalytic activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 42 grams of copper acetate, 27.6 ml of ethyl orthosilicate, and 300 ml of ethanol were added to the reactor, and the solution was stirred. Heating reaction and aging for 4 hours; filtering; drying at 120°C for 16 hours, and roasting at 400°C for 4 hours. Get CuO(65%wt) / SiO 2 (35%wt) hydrogenation catalyst. The above-mentioned catalyst is crushed into small particles, sieved, and 60-80 mesh particles are taken for later use.

Embodiment 2

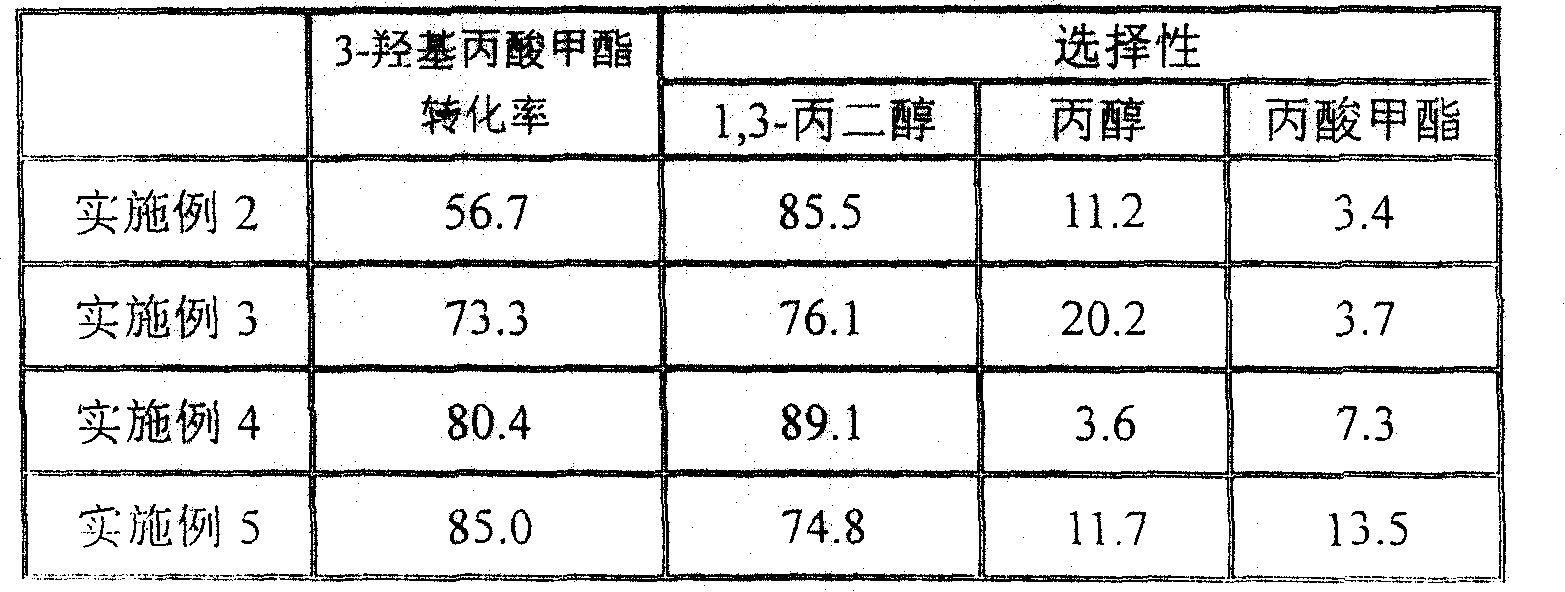

[0024] The above 2.0g catalyst particles were reduced with hydrogen at 350°C for 3 hours, and 30ml of methanol, 3g of methyl 3-hydroxypropionate and activated catalyst were added into a 100ml reactor. Hydrogenation reaction was carried out at 150° C. and 9.5 MPa for 20 hours. The catalyst was isolated and sampled for gas chromatographic analysis. The results are shown in Table 1.

Embodiment 3

[0026] The above 2.0g catalyst particles were reduced with hydrogen at 350°C for 4 hours, and 30ml of methanol, 3g of methyl 3-hydroxypropionate and activated catalyst were added to a 100ml reactor. Hydrogenation reaction was carried out at 150° C. and 9.5 MPa for 20 hours. The catalyst was isolated and sampled for gas chromatographic analysis. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com