Dynamic electrolyte for lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of electrolyte for lithium-ion batteries, can solve problems affecting battery capacity and service life, achieve high capacity, good cycle life, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ethylene carbonate, propylene carbonate, methyl propyl carbonate, and dipropyl carbonate of the carbonate solvent are mixed uniformly according to 26.43%, 11.32%, 12.94%, and 24.81% of the total liquid weight, and then 12.5 %LiPF 6 , add in three times on average, the time interval between each addition is 1.5 to 2.0 hours, shake well after adding, and then add film-forming additives of vinylene carbonate 1.0% and propylene sulfite 2.0%, anti-overfilling additive cyclohexylbenzene 7.0%, flame retardant trifluoromethyl phosphate 2.0%. The entire preparation process of the electrolyte is operated in a glove box, the glove box is in an argon environment, the temperature in the box is controlled within 25°C, and the moisture is below 1ppm.

[0032] This electrolyte solution was injected into the battery and tested.

[0033] The batteries used are:

[0034] Preparation of positive electrode: active material LiCoO 2 The content of carbon black is 94%, carbon black is 3.0%...

Embodiment 2-7

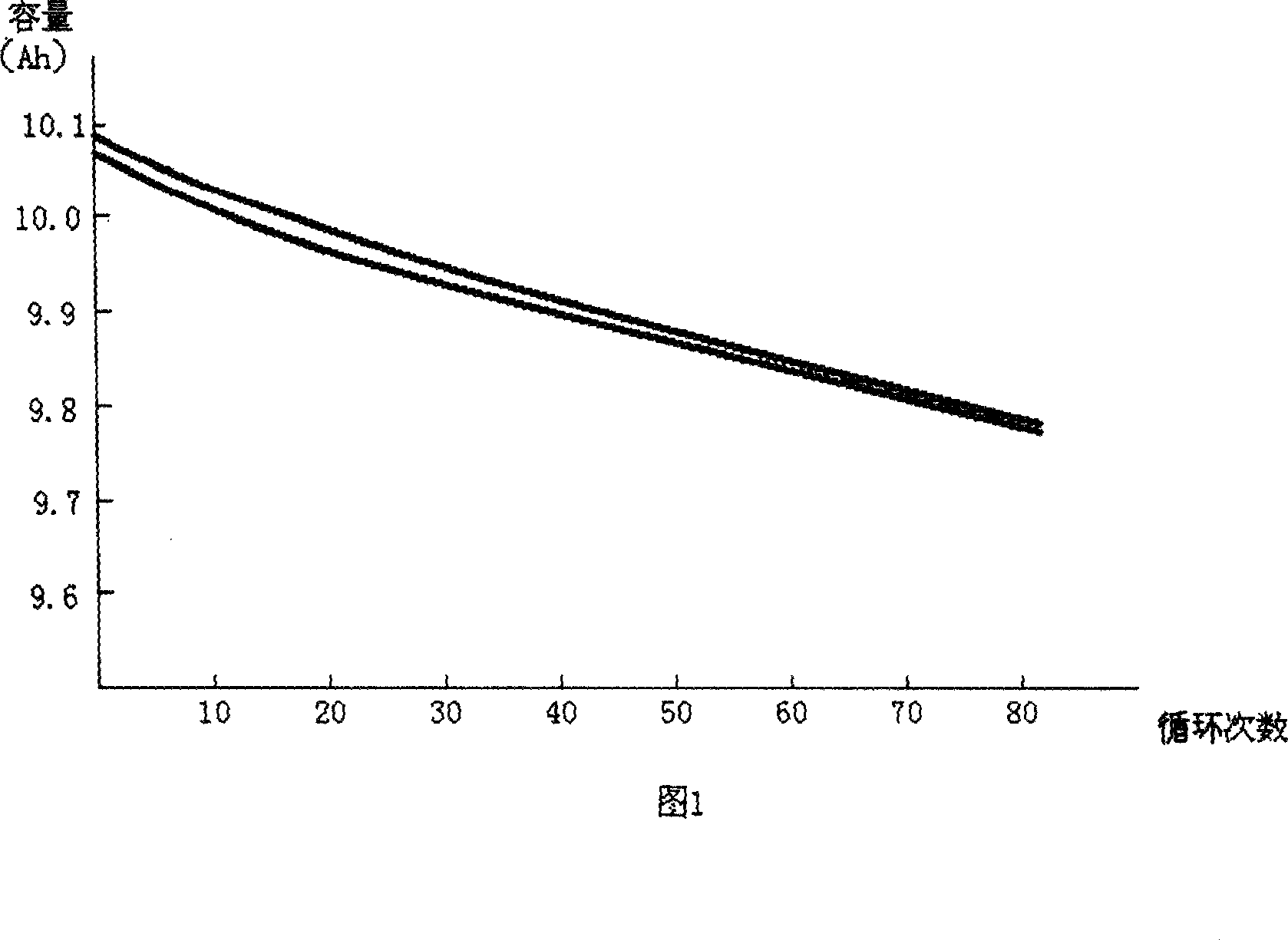

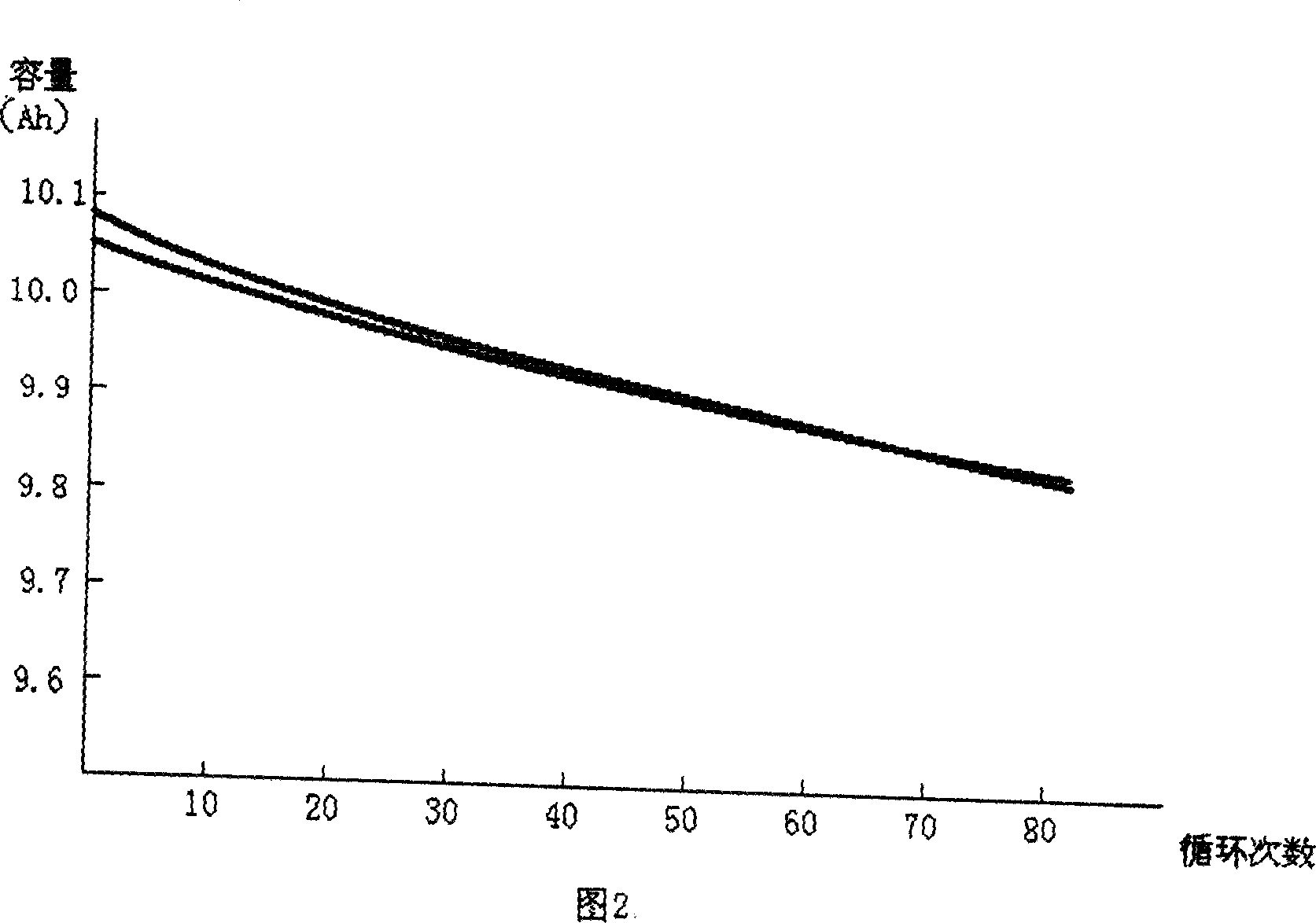

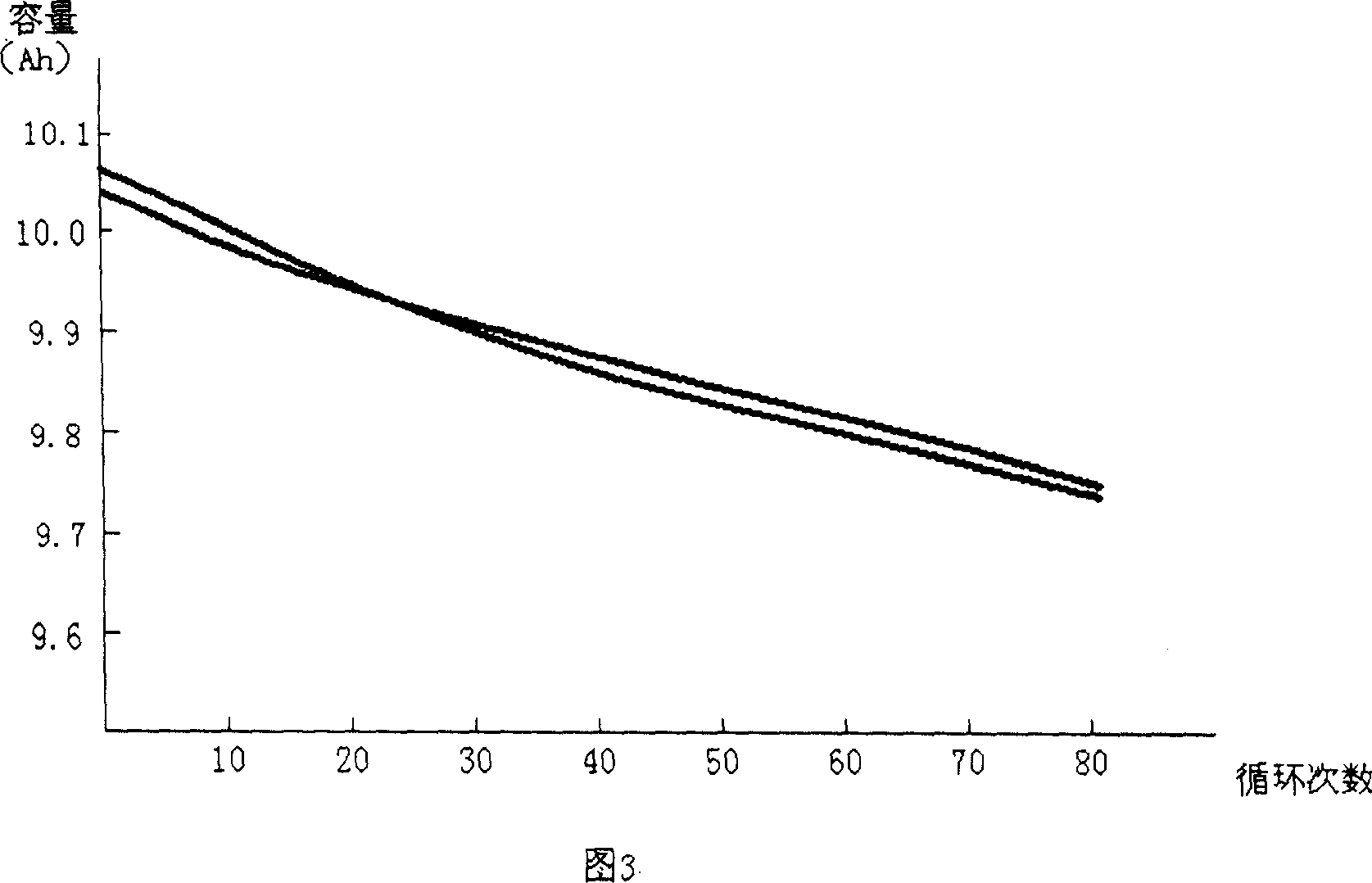

[0047] Example 1

Embodiment 8

[0049] With embodiment 1, just change the cyclohexylbenzene of anti-overcharge additive into p-xylylene dimethyl ether, change the trifluoromethyl phosphate of flame retardant into 2,2,2-trifluoroethyl phosphate, and The ethylene carbonate in the film-forming additive is replaced by 1,3-propiolactone sulfonate, the propylene sulfite is replaced by vinyl sulfite, LiPF 6 Replaced by Li(CF 3 SO 2 ) 2 N and do the various tests described in Example 1 with regard to the resulting electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com