Additive composition for preparing electrolyte, electrolyte containing additive composition and lithium ion secondary battery

A lithium secondary battery and electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, organic electrolytes, etc., can solve the problem of unsatisfactory high and low temperature performance and temperature range, reduced battery high and low temperature cycle life, sulfuric acid Solve problems such as low salt solubility, and achieve the effects of being beneficial to the storage and transportation process, low-temperature storage expansion, and good low-temperature circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of electrolyte for lithium secondary battery

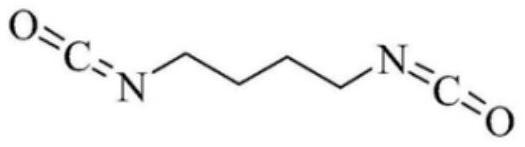

[0059] The electrolyte of the lithium secondary battery is lithium hexafluorophosphate (LiPF 6 ) is a lithium salt, with a mixture of ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) as a non-aqueous organic solvent, accounting for 61.99% of the total mass of the electrolyte, of which ethylene carbonate , ethyl methyl carbonate, diethyl carbonate mass ratio is 3:5:2. The additives are compound 1 and lithium bisfluorosulfonimide, accounting for 2% and 35% of the total mass of the electrolyte, respectively. Li 2 SO 4 The content is 0.01%.

[0060] (2) Preparation of positive electrode sheet for lithium secondary battery

[0061] 960g of positive electrode active material lithium nickel cobalt manganate (LiN 0.6 co 0.2 mn 0.2 o 2 ), 20g conductive agent Super-P, and 20g binder PVDF were dissolved in 320g solvent N-methylpyrrolidone according to the mass ratio of 96:2.0:...

Embodiment 2

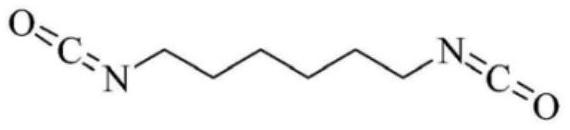

[0067] Prepare lithium secondary battery according to the method for embodiment 1, difference is that the electrolyte of lithium secondary battery accounts for lithium hexafluorophosphate (LiPF6) of 1% of electrolyte gross mass as lithium salt, and non-aqueous organic solvent is ethylene carbonate (EC) , ethyl methyl carbonate (EMC), and diethyl carbonate (DEC), accounting for 64.18% of the total mass of the electrolyte, with a mass ratio of 3:5:2. The additives are compound 2 and lithium bisfluorosulfonimide, accounting for 1.8% and 33% of the total mass of the electrolyte, respectively. Li 2 SO 4 The content is 0.02%. The cathode material used in lithium secondary batteries is LiNi 0.8 co 0.1 mn 0.1 o 2 , the negative electrode material is silicon carbon.

Embodiment 3

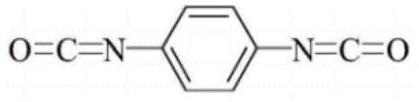

[0069] A lithium secondary battery was prepared according to the method of Example 1, except that the non-aqueous organic solvent was ethylene carbonate (EC), ethyl methyl carbonate (EMC), diethyl carbonate (DEC), accounting for 67.27% of the total mass of the electrolyte , the mass ratio is 3:5:2. The additives are compound 3 and lithium bisfluorosulfonyl imide, accounting for 1.7% and 30% of the total mass of the electrolyte, respectively, and lithium hexafluorophosphate (LiPF6) is a lithium salt and accounting for 1% of the total mass of the electrolyte. Li 2 SO 4 The content is 0.03%. The cathode material used in lithium secondary batteries is LiNi 0.8 co 0.15 Al 0.05 o 2 , the negative electrode is graphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com