Methyl propionate preparation method

A technology for methanol and carbon monoxide, applied in the field of preparing methyl propionate, can solve the problems of high price, cumbersome preparation of ionic liquid catalysts, high energy consumption for separation of homogeneous palladium catalysts, etc., and achieves easy separation, high catalyst activity, and simple preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

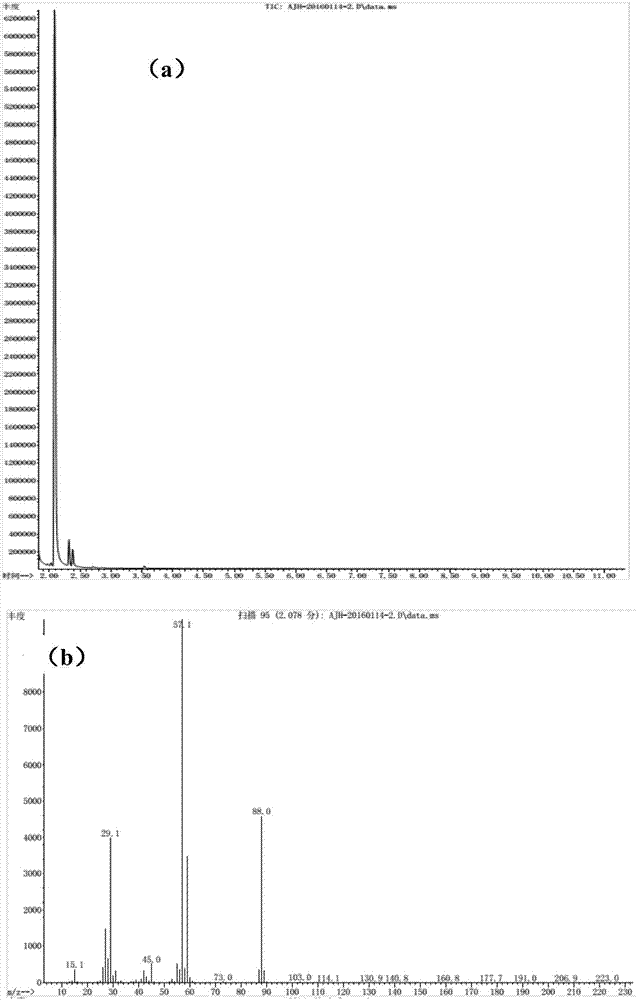

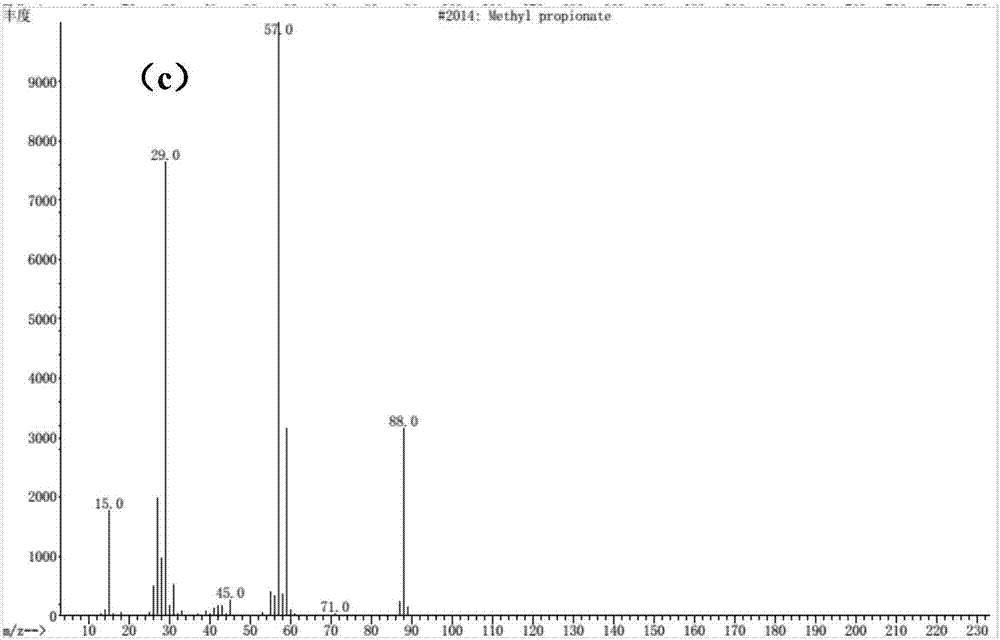

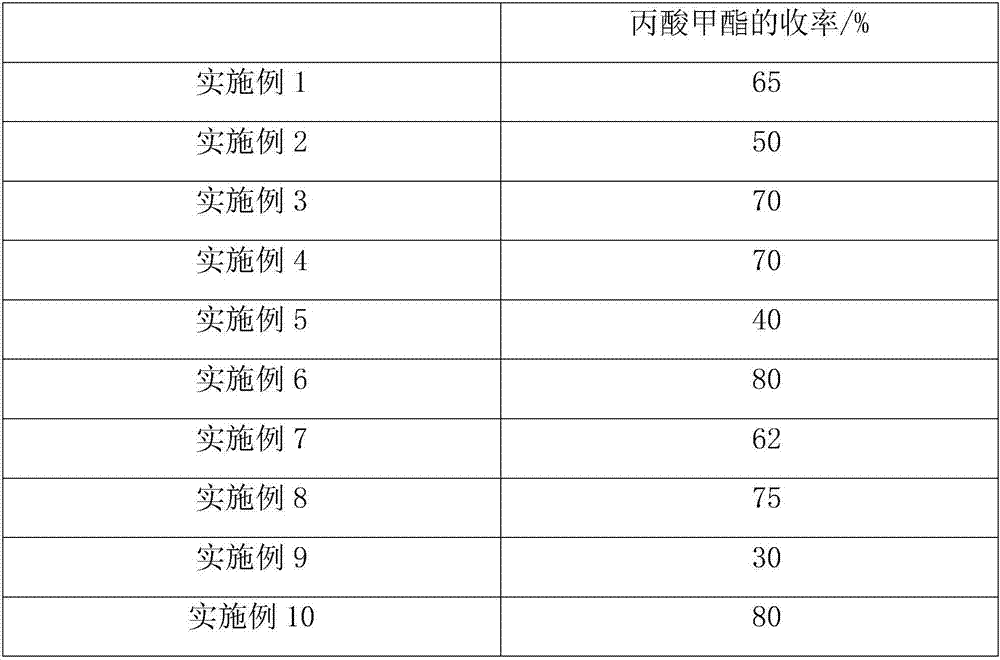

Embodiment 1

[0038] In a 50mL Teflon-lined reactor, weigh 0.15g of 2wt%Ru / TiO 2 Catalyst, add 4mL of methanol, put in a magnet, fill with 1MPa ethylene and 1.3MPa carbon monoxide gas respectively, airtight, stir and react at 180°C for 8h, after the reaction, confirm the product composition by mass spectrometry, the product mass spectrum and the standard product mass spectrum Figure 1 To, methyl propionate. The product was detected and quantified by gas chromatography, and the yield of methyl propionate is shown in Table 1.

Embodiment 2

[0040] In a 50mL Teflon-lined reactor, weigh 0.15g of 2wt%Ru / CeO 2 Catalyst, add 4mL of methanol, put in a magnet, fill with 1MPa ethylene and 0.1MPa carbon monoxide gas respectively, airtight, stir and react at 180°C for 8h, after the reaction, confirm the composition of the product by mass spectrometry, the mass spectrum of the product and the mass spectrum of the standard product Figure 1 To, methyl propionate. The product was detected and quantified by gas chromatography, and the yield of methyl propionate is shown in Table 1.

Embodiment 3

[0042] In a 50 mL Teflon-lined reactor, weigh 0.15 g of 10 wt% Ru / CeO 2 Catalyst, add 4mL of methanol, put in a magnet, fill with 0.5MPa ethylene and 0.5MPa carbon monoxide gas respectively, airtight, stir and react at 180°C for 8h, after the reaction, confirm the composition of the product by mass spectrometry, the mass spectrum of the product and the mass spectrum of the standard product Figure 1 To, methyl propionate. The product was detected and quantified by gas chromatography, and the yield of methyl propionate is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com