Cleaning agent for optical glass

A technology of optical glass and cleaning agent, applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc. , Excellent cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

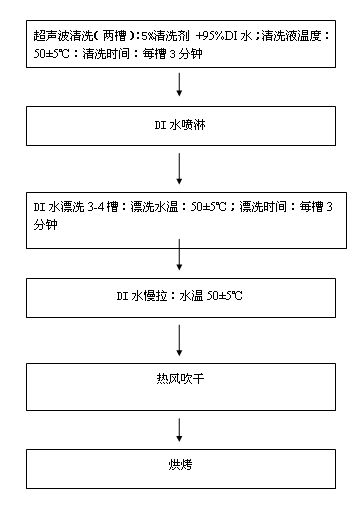

Method used

Image

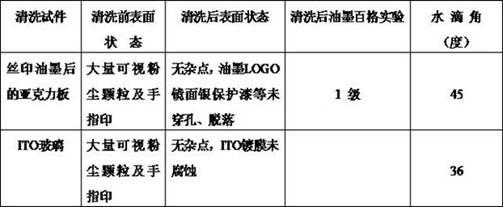

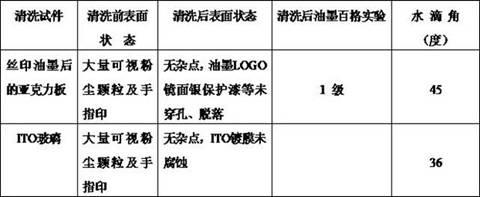

Examples

Embodiment 1

[0076] The composition and content of optical glass cleaning agent are shown in the table below:

[0077] serial number Component Content (W%) weight percentage 1 C21 dibasic acid 2 2 dodecylbenzenesulfonic acid 6 3 95%NaOH 2 4 Fatty alcohol polyoxyethylene ether AEO 9 2 5 Disodium Nonylphenol Polyoxyethylene Ether Succinate Monoester Sulfonate 2 6 EDTA-4Na 2 7 sodium gluconate 4 8 Diethanolamine 10 9 DI water 70

[0078] The manufacture method of making 100Kg above-mentioned optical glass cleaning agent is as follows:

[0079] Weigh materials 1 and 2, namely 2Kg of C21 dibasic acid and 6kg of dodecylbenzenesulfonic acid, put them into a mixing tank, add 10Kg of DI water first, and then stir;

[0080] Weigh 2kg of material 3, namely 95% NaOH, add 10Kg of DI water to dissolve, put it into a mixing bucket, and stir fully to form a clear liquid;

[0081] Weigh the remaining material, namely fatty a...

Embodiment 2

[0091] The composition and content of optical glass cleaning agent are shown in the table below:

[0092] serial number Component Content (W%) 1 C21 dibasic acid 4 2 dodecylbenzenesulfonic acid 10 3 95%NaOH 4 4 Fatty alcohol polyoxyethylene ether AEO 9 6 5 Disodium Nonylphenol Polyoxyethylene Ether Succinate Monoester Sulfonate 4 6 EDTA-4Na 4 7 sodium gluconate 8 8 Diethanolamine 20 9 DI water 40

[0093] The manufacture method of making 100Kg above-mentioned optical glass cleaning agent is as follows:

[0094] Weigh materials 1 and 2 respectively, namely 4Kg of C21 dibasic acid and 10kg of dodecylbenzenesulfonic acid, put them into the mixing tank, add 10Kg of DI water first, and then stir;

[0095] Weigh 4kg of material 3, namely 95%NaOH, add 12Kg of DI water to dissolve it, put it into a mixing bucket, and stir it fully to form a clear liquid;

[0096] Weigh the remaining material, namely fat...

Embodiment 3

[0106] The composition and content of optical glass cleaner are shown in the table below:

[0107] serial number Component Content (W%) 1 C21 dibasic acid 3 2 dodecylbenzenesulfonic acid 6 3 95%NaOH 2.5 4 Fatty alcohol polyoxyethylene ether AEO 9 4.5 5 Disodium Nonylphenol Polyoxyethylene Ether Succinate Monoester Sulfonate 3 6 EDTA-4Na 3 7 sodium gluconate 6 8 Diethanolamine 15 9 DI water 57

[0108] The manufacture method of making 100Kg above-mentioned optical glass cleaning agent is as follows:

[0109] Weigh materials 1 and 2 respectively according to the formula quantity, i.e. 3Kg of C21 dibasic acid and 6kg of dodecylbenzenesulfonic acid, put them into the mixing tank, add 10Kg of DI water first, and then stir;

[0110]Weigh 2.5kg of material 3, namely 95% NaOH, add 12Kg of DI water to dissolve it, put it into a mixing bucket, and stir it fully to form a clear liquid;

[0111] Weigh the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com