Fluorine silicon-modified acrylic ester emulsion and preparation method thereof

An acrylate, fluorosilicon modified technology, used in polyurea/polyurethane coatings, coatings, paints containing biocides, etc., can solve the problem of high porosity reducing the compactness of the paint film, and the stain is easy to penetrate into the paint film and paint. Fouling resistance decline and other problems, to achieve the effect of maintaining stability and effectiveness, good electrical conductivity, and improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

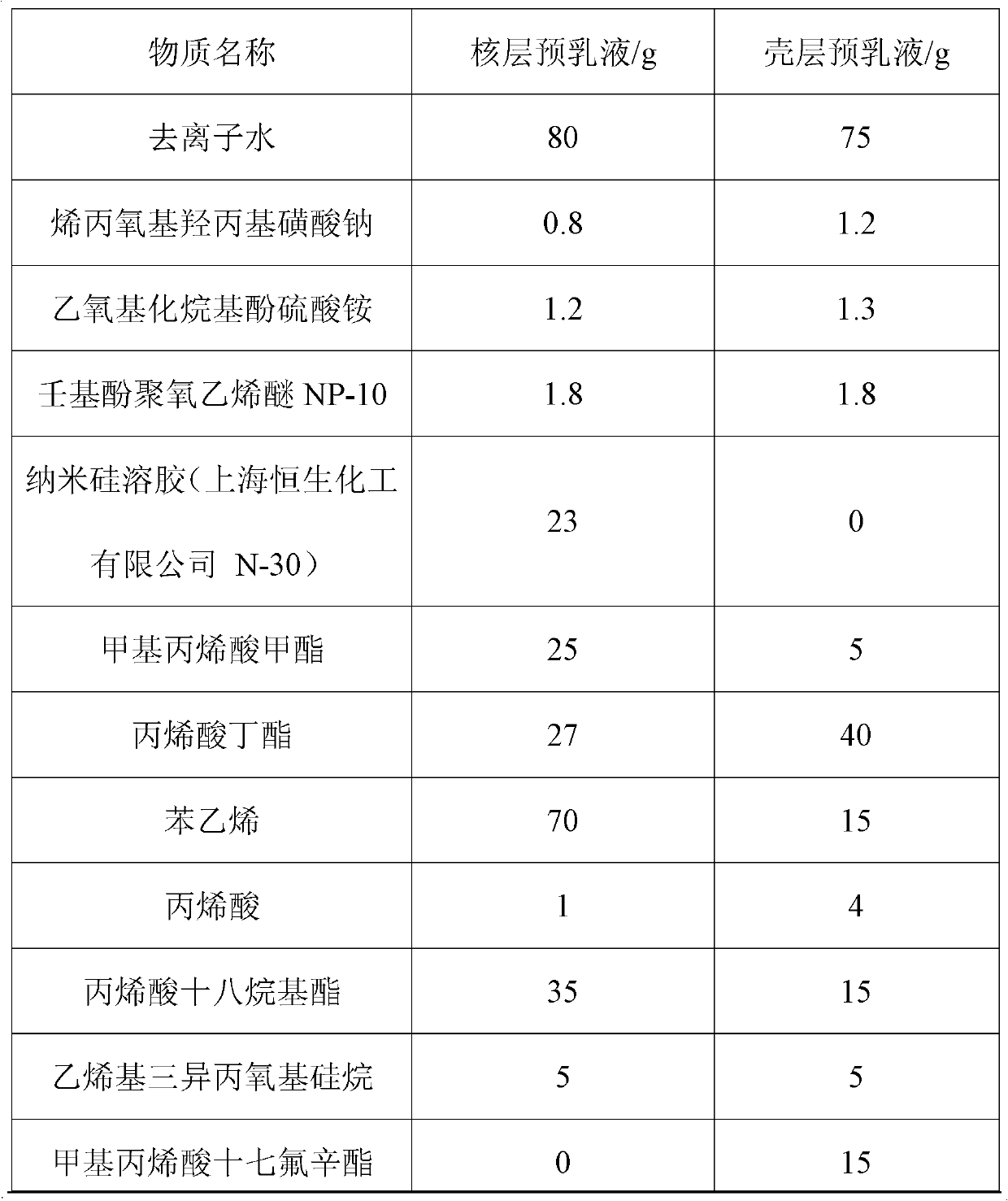

[0056] One, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

[0057] The raw material consumption of table 1 core-shell two-layer pre-emulsion

[0058]

[0059] The core layer pre-emulsion and the shell layer pre-emulsion are respectively according to the above composition, mixed and stirred for 20-30min at a rotation speed of 500-600rpm, and set aside.

[0060] Table 2 Initiator aqueous solution

[0061] Substance name Initial initiator / g Dropping initiator / g sodium persulfate 0.35 1.00 Deionized water 6 48

[0062] The emulsion viscosity was measured with a NDJ-1 rotary viscometer. The measurement conditions are as follows: the test temperature is 25°C; the No. 1 rotor is used; the rotation speed is 60r / min, see GB / T1723-1993. The same below.

[0063] Two, the preparation of described fluorosilicon modified acrylate emulsion is as follows:

[0064] Put 100 grams of deionized water, 0.4 g...

Embodiment 2

[0075] One, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

[0076] The raw material consumption of table 4 core-shell two-layer pre-emulsion

[0077]

[0078] The core layer pre-emulsion and the shell layer pre-emulsion are respectively made according to the above composition, mixed and stirred for 20-30 minutes at a rotation speed of 500-600 rpm, and stirred evenly for later use.

[0079] Table 5 Initiator aqueous solution

[0080] Substance name Initial initiator / g Dropping initiator / g potassium persulfate 0.8 2.2 Deionized water 10 50

[0081] [0081] Two, the preparation of described fluorosilicon modified acrylate emulsion is as follows:

[0082] Put 90 grams of deionized water, 0.5 grams of sodium alkyl polyoxyethylene sulfonate, 0.5 grams of NP-40 and 3.0 grams of sodium bicarbonate into the reaction kettle and stir evenly, then add 44 grams of core layer pre-emulsion, and heat up t...

Embodiment 3

[0090] One, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

[0091] The raw material consumption of table 7 core-shell two-layer pre-emulsion

[0092]

[0093]

[0094] The core layer pre-emulsion and the shell layer pre-emulsion are respectively according to the above composition, mixed and stirred for 20-30min at a rotation speed of 500-600rpm, and set aside.

[0095] Table 8 Initiator aqueous solution

[0096] Substance name Initial initiator / g Dropping initiator / g Ammonium persulfate 0.6 1.4 Deionized water 10 50

[0097] Two, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

[0098] 105 grams of deionized water, 0.5 grams of 1-propenyloxy-2-hydroxypropanesulfonate sodium, 0.6 grams of OP-10 and 1.5 grams of sodium carbonate were put into the reactor and stirred evenly, then 37 grams of the core layer pre-emulsion was added and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com