Nano stannic oxide-graphene composite as well as preparation method and application thereof

A technology of nano-tin dioxide and composite materials, which is applied in the direction of tin oxide, etc., can solve the problems of response recovery time influence, low sensitivity and selectivity, and achieve fewer synthesis steps, simple operation methods, broad development prospects and practical application space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

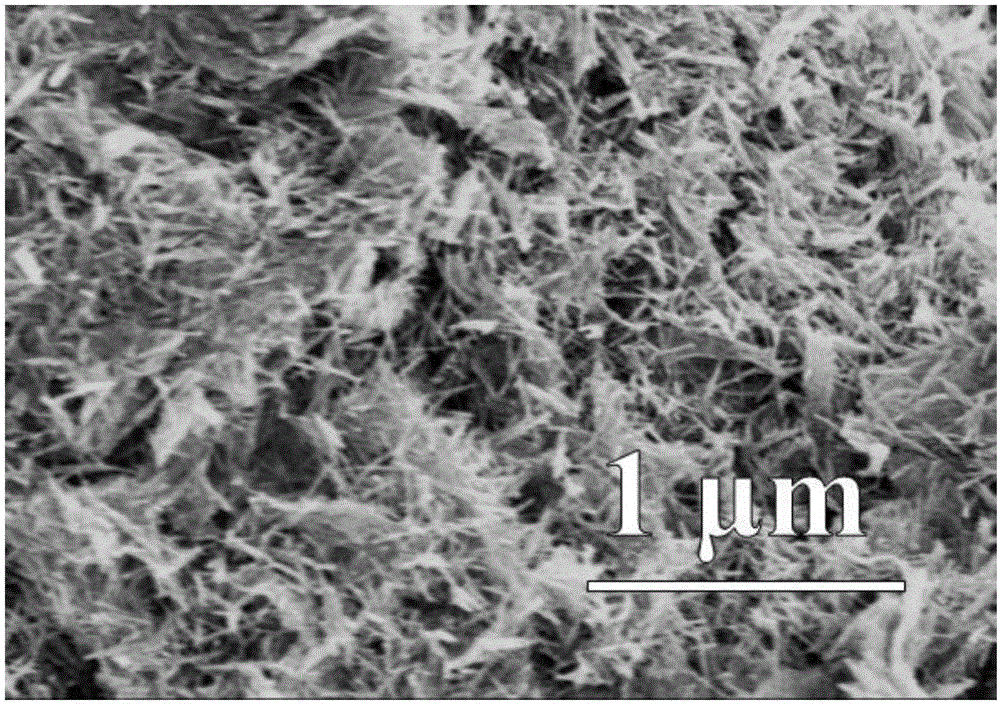

Image

Examples

Embodiment 1

[0037] A method for preparing a nano-tin dioxide and graphene composite material capable of specifically responding to ammonia at room temperature, the specific steps are as follows:

[0038] (1) Seed crystal adsorption: take 20ml GO aqueous solution (2mg / ml) and add 10ml H 2 O in a total of 30ml solution ultrasonically dispersed for 30min. Analytical balance weighs a certain amount of SnCl 4 ·5H 2 O, added to the sonicated GO aqueous solution, so that the Sn 4+ The concentration is 0.005mol / L. Placed on a magnetic stirrer, fully stirred for 12 hours to make the surface of GO sheets adsorb Sn4+ Create active sites. The solid obtained after repeated stirring was washed twice with deionized water and ethanol respectively to remove excess ions. Dissolve the solid obtained after washing with 10ml of distilled water, and ultrasonicate for 15 minutes to obtain a brown uniform dispersion, which is used as a seed crystal adsorption solution for future use.

[0039] (2) Hydrother...

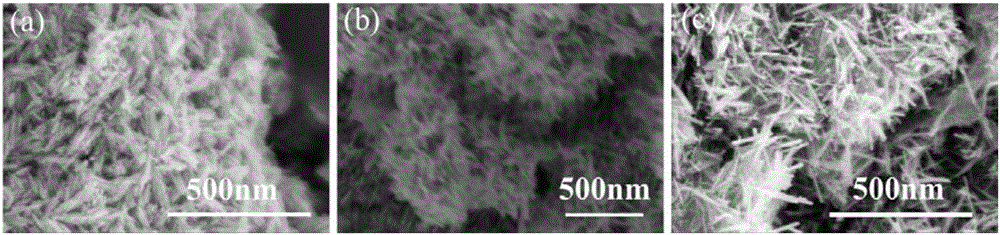

Embodiment 2

[0044] A method for preparing a nano-tin dioxide and graphene composite material with specific response to ammonia at room temperature, the specific steps are as follows:

[0045] (1) Seed crystal adsorption: Graphene oxide (GO) aqueous solution, measure GO aqueous solution (2mg / ml) containing different GO masses (5mg, 10mg, 20mg) and add 20ml H 2 O Ultrasonic dispersion for 30min. Analytical balance weighs a certain amount of SnCl 4 ·5H 2 O, added to different volumes of sonicated GO aqueous solution, so that Sn 4+ The concentration is 0.005mol / L. Placed on a magnetic stirrer, fully stirred for 12 hours to make the surface of GO sheets adsorb Sn 4+ Create active sites. The solid obtained after repeated stirring was washed twice with deionized water and ethanol respectively to remove excess ions. Dissolve the solid obtained after washing with 10ml of distilled water, and ultrasonicate for 15 minutes to obtain a brown uniform dispersion, which is used as a seed crystal ad...

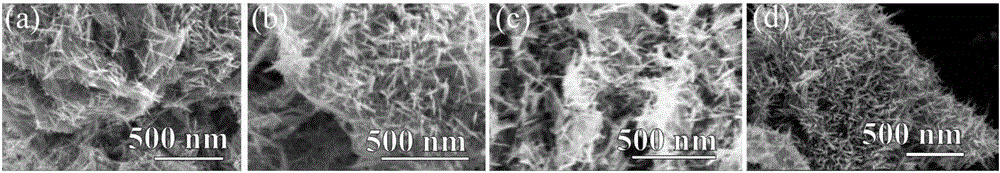

Embodiment 3

[0049] A method for preparing a nano-tin dioxide and graphene composite material with specific response to ammonia at room temperature, the specific steps are as follows:

[0050] (1) Seed adsorption: Graphene oxide (GO) aqueous solution, take 20ml GO aqueous solution (2mg / ml) and add 20ml H 2 O Ultrasonic dispersion for 30min. Analytical balance weighs a certain amount of SnCl 4 ·5H 2 O was added to the sonicated GO aqueous solution, so that the Sn 4+ The concentration is 0.005mol / L. Placed on a magnetic stirrer, fully stirred for 12 hours to make the surface of GO sheets adsorb Sn 4+ Create active sites. The solid obtained after repeated stirring was washed twice with deionized water and ethanol respectively to remove excess ions. Dissolve the solid obtained after washing with 10ml of distilled water, and ultrasonicate for 15 minutes to obtain a brown uniform dispersion, which is used as a seed crystal adsorption solution for future use.

[0051] (2) Hydrothermal proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com