Method for quickly growing large-size SiC (Silicon Carbide) single crystal

A silicon carbide single crystal, fast technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of large investment, inability to meet industrial production, and long time consumption, so as to achieve low equipment investment and save Raw material synthesis steps, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

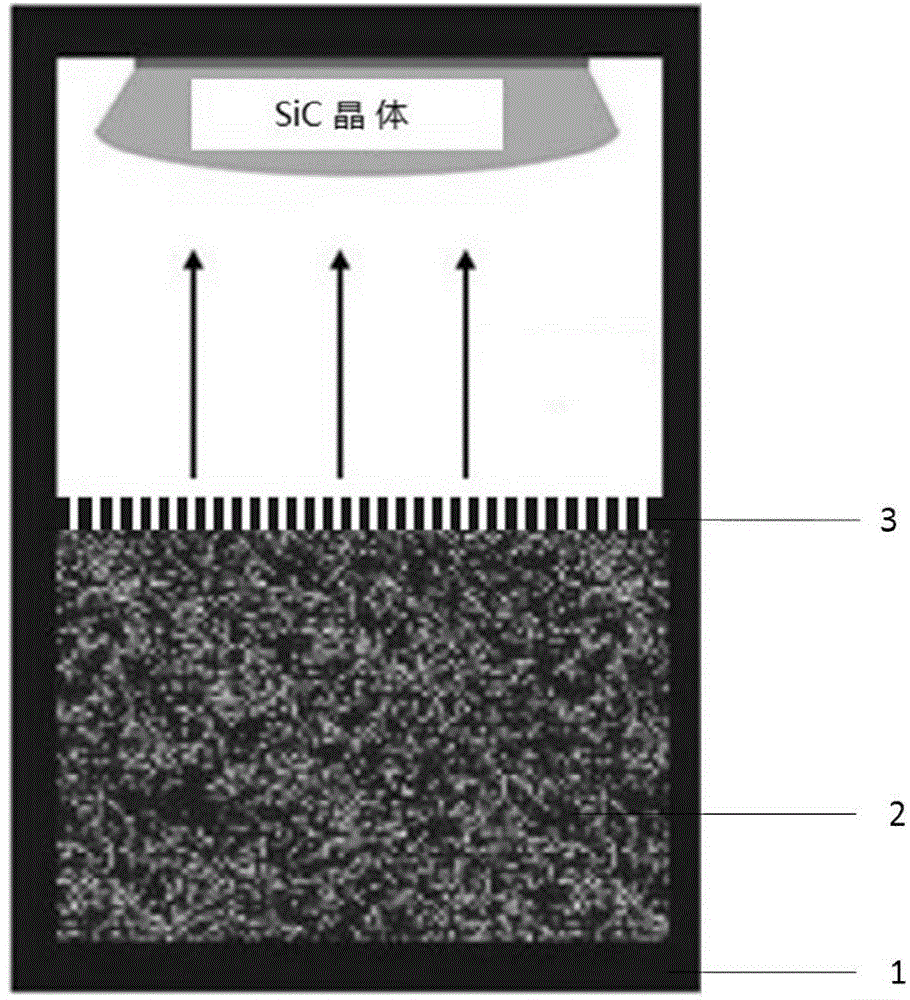

[0033] A method for rapidly growing large-size silicon carbide single crystals. The source materials are directly silicon powder and carbon powder. The surface of the silicon powder and carbon powder mixture is covered with a porous graphite sheet. After the powder is synthesized in situ, it is grown by PVT method. Large size SiC single crystal. Specific steps are as follows:

[0034] (1) The silicon powder particle size is 10 μm, and the carbon powder particle size is 10 μm. After the silicon powder and carbon powder are mixed evenly at a molar ratio of 1:1, they are evenly spread on the bottom of the graphite crucible. The holes on the porous graphite sheet placed on the surface of the mixture in the crucible are circular holes and arranged periodically. The thickness of the graphite sheet is 1 mm, the diameter of the circular holes distributed periodically on it is 5 μm, and the space distance is 2 mm, such as Figure 4 shown.

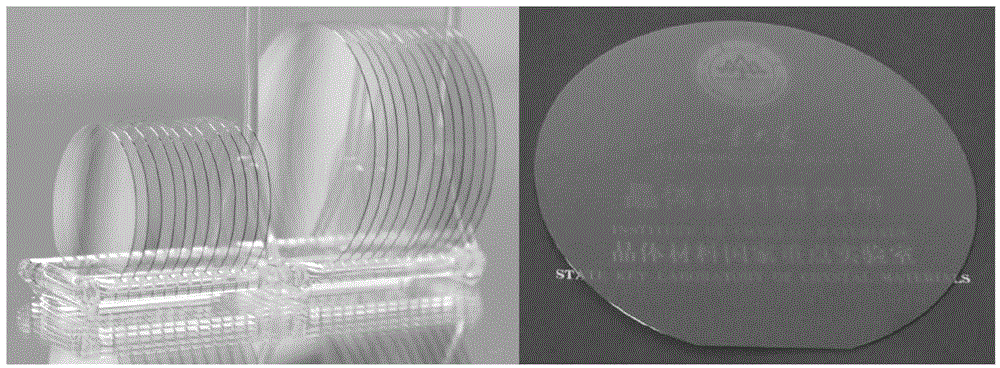

[0035] (2) 6H-SiC single crystal is used ...

Embodiment 2

[0038] A method for rapidly growing a large-size silicon carbide single crystal, the steps are as follows:

[0039] In step (1), the silicon powder and carbon powder are mixed in a molar ratio of 1:1, based on the total weight of the mixed powder of silicon powder and carbon powder, 1% boron carbide solid powder is added, and the particle size is 5 μm , the particle size of silicon powder is 100 μm, and the particle size of carbon powder is 100 μm. Spread the above-mentioned mixture on the bottom of the graphite crucible, place a porous graphite sheet on the surface, the thickness of the porous graphite sheet is 20 mm, and the regular triangle holes with a side length of 90 μm are periodically distributed on it, as Figure 5 shown.

[0040] Step (2) is as described in Example 1, except that the size of the seed crystal is 3 inches, the temperature for synthesizing the SiC source material is between 2000° C., the pressure is controlled at 900 mbar, and the reaction time is 5 h...

Embodiment 3

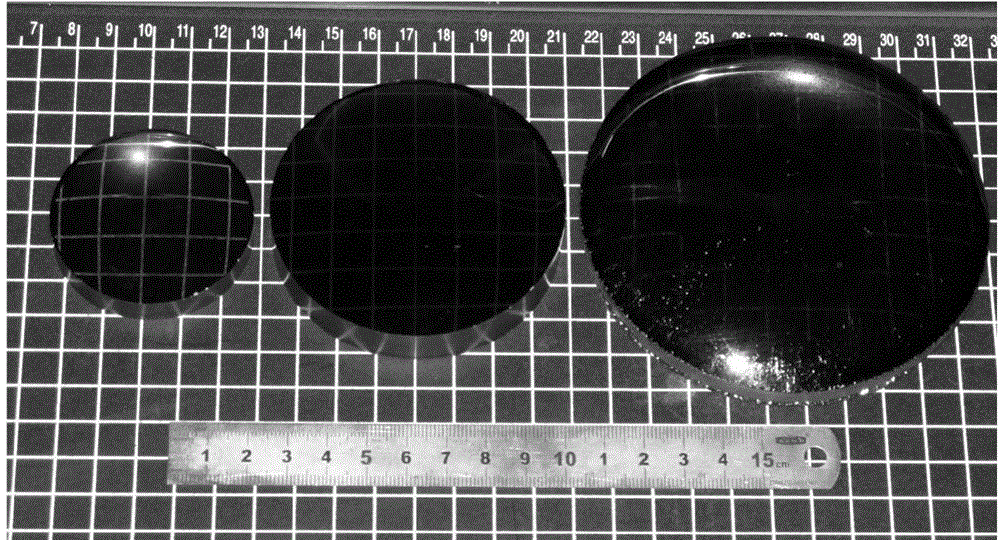

[0043] A method for rapidly growing large-scale silicon carbide single crystals, as described in Example 2, the difference is that vanadium carbide powder with a particle size of 3 μm is added to the mixed powder of silicon powder and carbon powder, and the total of silicon powder and carbon powder The weight to vanadium carbide powder weight ratio is 500:1, the silicon powder particle size is 50 μm, and the carbon powder particle size is 50 μm. The thickness of the porous graphite sheet is 10 mm, and the side length of the regular triangle hole is 45 μm. The temperature of the synthetic source material was 1800° C., the pressure was controlled at 850 mbar, and the reaction time was 4 hours. The size of the seed crystal is 6 inches, the temperature for growing single crystal is 2400° C., the pressure is 30 mbar, and the growth time is 40 hours. The grown SiC single crystal is semi-insulating and has a diameter of 6 inches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com