Method for preparing Salen-metal complex

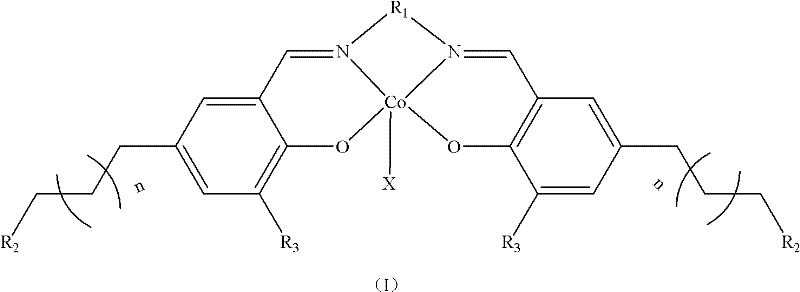

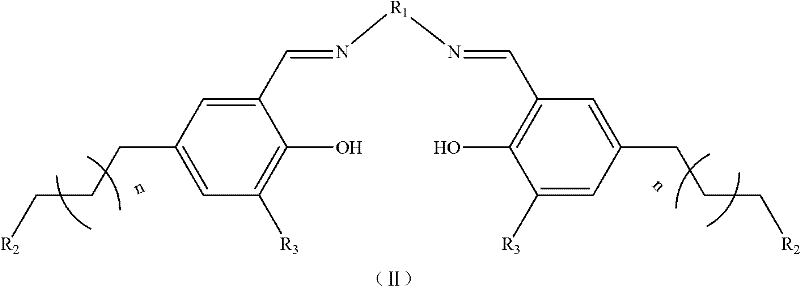

A technology of metal complexes and complexes, which is applied in the direction of cobalt organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem that there is no clear preparation method and cost of catalysts High, cumbersome steps and other problems, to achieve the effect of simple method, low cost, high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

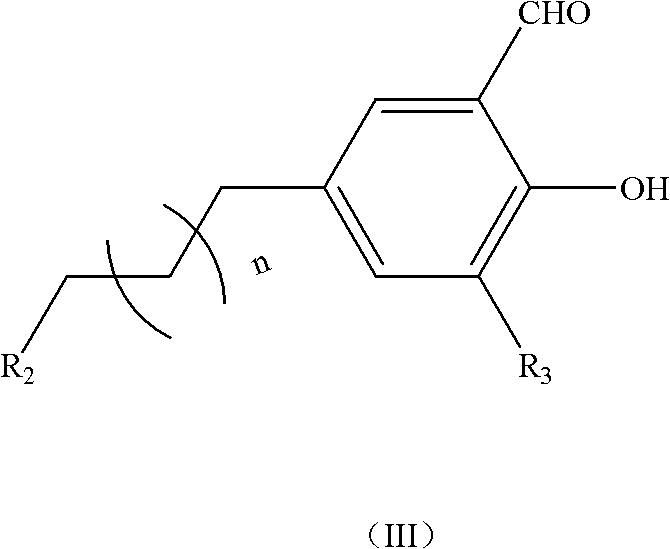

[0031] Embodiment 1: salicylaldehyde derivative (III 1 )Synthesis

[0032] Salicylaldehyde derivatives (III 1 ) synthetic route is as follows:

[0033]

[0034] Take a 50mL three-necked flask under an argon atmosphere, add 10mmol 3-(3-tert-butyl-4-hydroxy)methyl phenylpropionate, dissolve in 30ml tetrahydrofuran, add 10mmol lithium tetrahydrogen to the three-necked flask, and react at reflux temperature 12 hours, cooled to room temperature, added 40% hydrobromic acid 20ml, stirred at room temperature for 6 hours, concentrated to the constant quality of crude product, crude product column chromatography (SiO 2 , petroleum ether / ethyl acetate, V / V=10:1), the second component was collected, concentrated by suspension evaporation, and dried under a vacuum of 0.1MPa until the product quality was constant to obtain 2-tert-butyl 4-bromopropyl Phenol, yield 92%; take a 50mL three-neck flask under argon gas, add 5mmol 2-tert-butyl 4-bromopropylphenol, 10mmol paraformaldehyde, 10m...

Embodiment 2

[0035] Embodiment 2: salicylaldehyde derivative (III 2 )Synthesis

[0036] Salicylaldehyde derivatives (III 2 ) synthetic route is as follows:

[0037]

[0038] Take a 50mL three-neck flask under argon atmosphere, add 10mmol anhydrous aluminum trichloride, 10mmol p-(3-bromopropyl)phenol and 10mmol 2-chloropropane, react at reflux temperature for 16 hours, cool to room temperature, and concentrate to the crude product Constant quality, crude product column chromatography (SiO 2 , petroleum ether / ethyl acetate, V / V=25:1), the second component was collected, concentrated by suspension evaporation, and dried under a vacuum of 0.1MPa until the product quality was constant to obtain 2-isopropyl 5-bromopropyl Phenol, yield 78%; take a 50mL three-necked flask under argon gas, add 5mmol 2-isopropyl 4-bromopropylphenol, 10mmol paraformaldehyde, 10mmol tin tetrachloride and 30mL toluene into the three-necked flask, reflux Reaction 12 hours under the temperature, be cooled to room ...

Embodiment 3

[0039] Embodiment 3: salicylaldehyde derivative (III 3 )Synthesis

[0040] Replace 3-(3-tert-butyl-4-hydroxyl) methyl phenylpropionate in embodiment 1 with methyl p-hydroxyphenylacetate, other operation is with embodiment 1, obtains salicylaldehyde derivative (III 3 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com