Compound super-hydrophobic ocean antifouling paint as well as preparation method and application thereof

A marine anti-fouling and super-hydrophobic technology, applied in anti-fouling/underwater coatings, coatings, devices for coating liquids on surfaces, etc. ° and other problems, to achieve the effect of simple preparation process, excellent storage stability, and fewer synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Synthesis of linear acrylic resin

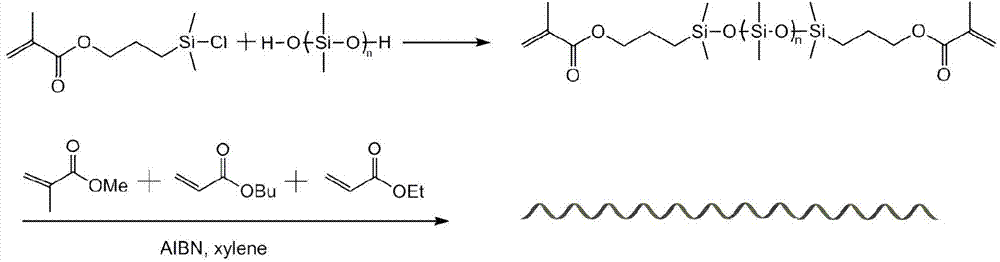

[0042] a. Synthesis of acryloxy polysiloxane I

[0043] In a three-necked flask equipped with a stirrer, a constant pressure dropping funnel, and a thermometer, 200 g of hydroxysilicone oil (average molecular weight is 400) was added, and then 221 g of γ-(methacryloyloxy)propyldimethylchlorosilane was weighed and passed through After the constant pressure dropping funnel was slowly added dropwise, the temperature was raised to 60° C. after stirring for 1 hour, and the temperature was maintained for 2 hours to obtain acryloxy polysiloxane I. Specifically, the acryloxy polysiloxane I was used at both ends Gamma-(methacryloyloxy)propyl and gamma-(methacryloyloxy)propylsilyl terminated polydimethylsilanes.

[0044] b. Synthesis of straight-chain acrylic resin

[0045] In a four-necked flask equipped with a stirrer, a reflux condenser, a constant-pressure dropping funnel, and a thermometer, add 50 g of xylene I, raise the temperature ...

Embodiment 2

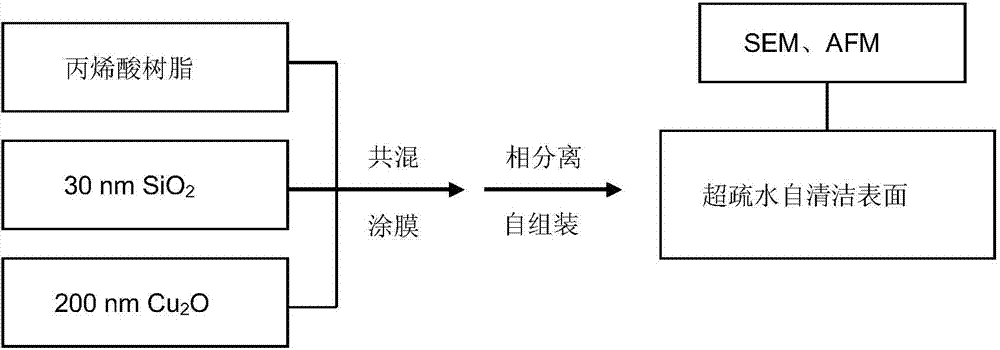

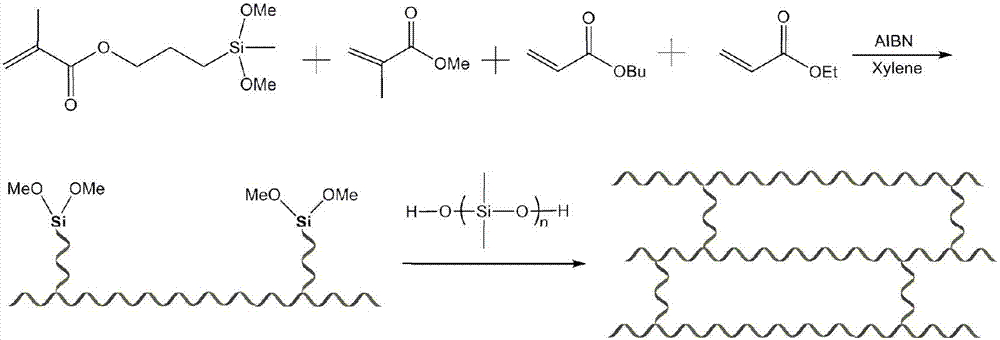

[0052] 1. Synthesis of cross-linked acrylic resin

[0053] In a four-necked flask equipped with a stirrer, a reflux condenser, a constant pressure dropping funnel, and a thermometer, add 200 g of xylene, raise the temperature to 110 °C, and weigh 14 g of γ-(methacryloyloxy) propyl dimethyl methane. The mixed solution B of chlorosilane, 166 g methyl methacrylate, 26 g ethyl acrylate, 40 g n-butyl acrylate, and 4 g azobisisobutyronitrile I was added dropwise through a constant pressure dropping funnel over 3 hours After completion, 1 g of azobisisobutyronitrile II was added, and after continuing the reaction for 3 hours, the temperature was lowered to 60° C., and 22 g of hydroxy silicone oil (average molecular weight was 400) was added to obtain a cross-linked acrylic resin.

[0054] The general synthetic route such as image 3 As shown, the acrylic resin prepared in this example also has low surface energy.

[0055] 2. The preparation of the composite super-hydrophobic marine...

Embodiment 3

[0057] 1. Synthesis of comb-type low surface energy acrylic resin

[0058] a. Synthesis of acryloxy polysiloxane II

[0059] In a three-necked flask equipped with a stirrer, a constant pressure dropping funnel and a thermometer, add 290 g of trimethylsilane-terminated hydroxy silicone oil (average molecular weight is 580, measured by GPC), and then weigh 110 g of γ-(methacryloyloxy) propyl dimethyl chlorosilane was slowly added dropwise through a constant pressure dropping funnel, stirring was continued for 1 hour, and then the temperature was raised to 60° C. and kept for 2 hours to obtain acryloxy polysiloxane II, which was acryloxy polysiloxane II. Oxane II is specifically polydimethylsilane terminated at both ends with γ-(methacryloyloxy)propyl and trimethylsilyl groups, respectively.

[0060] b. Synthesis of comb-type acrylic resin

[0061] In a four-necked flask equipped with a stirrer, a reflux condenser, a constant pressure dropping funnel, and a thermometer, 50 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com