Iron-doped cerium dioxide photocatalyst and preparation method thereof

A technology of ceria and photocatalyst, which is applied in the field of nanotechnology, can solve the problems of high cost, complicated preparation process, and low catalytic efficiency, and achieve the effect of simple production equipment, simple preparation process and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A non-iron-doped ceria photocatalyst whose molecular formula is CeO 2 .

[0048] The preparation method of above-mentioned a kind of iron-doped ceria photocatalyst, its preparation process specifically comprises the following steps:

[0049] (1) At room temperature, use deionized water to prepare an aqueous solution of cerium nitrate with a concentration of 0.1mol / L and an aqueous solution of sodium carbonate with a concentration of 0.5mol / L;

[0050] (2) Add 100ml of ferric nitrate aqueous solution with a concentration of 0.1mol / L dropwise to 60ml of an aqueous sodium carbonate solution with a temperature of 70°C and a concentration of 0.5mol / L at a rate of 2.5ml / min, and maintain the temperature during the dropwise addition The temperature is 70°C, and the rotation speed is 600rpm. After the dropwise addition, continue to control the temperature to 70°C, and the stirring speed is 600rpm to react for 30min, and the obtained reaction solution is naturally cooled to roo...

Embodiment 2

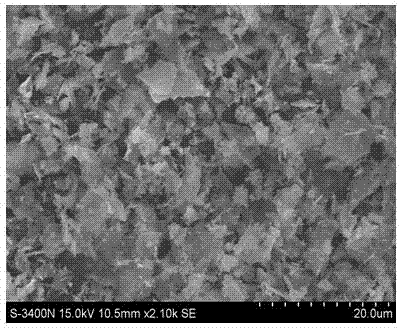

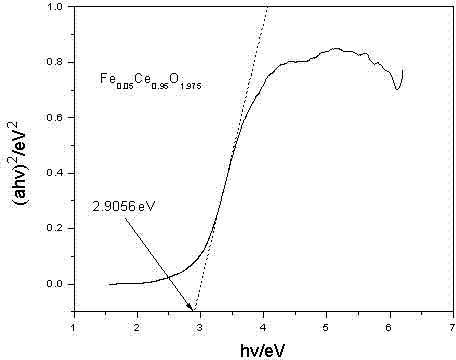

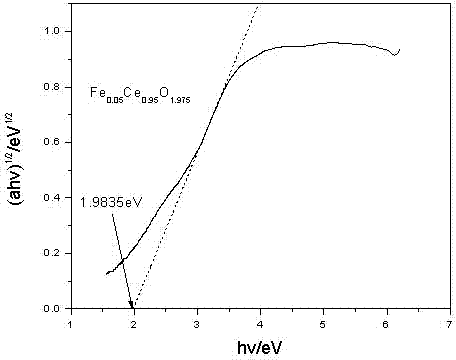

[0058] A kind of iron-doped ceria photocatalyst, its molecular formula is Fe x Ce 1-x o 2-0.5x , where X is 0.05.

[0059] The preparation method of above-mentioned a kind of iron-doped ceria photocatalyst, its preparation process specifically comprises the following steps:

[0060] (1) At room temperature, use deionized water to prepare an aqueous cerium nitrate solution with a concentration of 0.1mol / L, an aqueous solution of ferric nitrate with a concentration of 0.1mol / L, and an aqueous solution of sodium carbonate with a concentration of 0.5mol / L;

[0061] (2) Ultrasonically mix 5ml of ferric nitrate aqueous solution with a concentration of 0.1mol / L and 95ml of cerium nitrate aqueous solution with a concentration of 0.1mol / L to obtain a mixed aqueous solution of ferric nitrate and cerium nitrate. In the mixed aqueous solution of ferric nitrate and cerium nitrate, massage Calculation of mol ratio, that is, Ce:Fe is 0.95:0.05;

[0062] (3) Add the ferric nitrate and cer...

Embodiment 3

[0070] A kind of iron-doped ceria photocatalyst, its molecular formula is Fe x Ce 1-x o 2-0.5x , where X is 0.1.

[0071] The preparation method of above-mentioned a kind of iron-doped ceria photocatalyst specifically comprises the following steps:

[0072] (1) At room temperature, use deionized water to prepare an aqueous cerium nitrate solution with a concentration of 0.1mol / L, an aqueous solution of ferric nitrate with a concentration of 0.1mol / L, and an aqueous solution of sodium carbonate with a concentration of 0.5mol / L;

[0073] (2) Ultrasonically mix 90ml of ferric nitrate aqueous solution with a concentration of 0.1mol / L and 10ml of cerium nitrate aqueous solution with a concentration of 0.1mol / L to obtain a mixed aqueous solution of ferric nitrate and cerium nitrate. In the mixed aqueous solution of ferric nitrate and cerium nitrate, massage Calculation of mol ratio, that is, Ce:Fe is 0.9:0.1;

[0074] (3) Add the ferric nitrate and cerium nitrate mixed aqueous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com