Method for preparing spherical LFP (lithium iron phosphate)/carbon doped composite powder

A lithium iron phosphate and carbon composite technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of large material particles, difficulty in obtaining high-purity cathode materials, uneven mixing, etc., to improve conductivity and consistency. , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a spherical doped lithium iron phosphate / carbon composite powder, the molecular formula of the spherical doped lithium iron phosphate / carbon composite powder is: Li 1-x m x Fe 1-y M' y PO 4 / C (M , M' represent dopant ions). Its preparation method comprises the following steps:

[0025] (1) Raw material preparation: Ferric nitrate nonahydrate, phosphoric acid, lithium carbonate, doped metal ion salts and carbon source are used as raw materials, according to Li 1-x m x Fe 1-y M' y PO 4 (M, M' represent doping ions, x=0-0.05, y=0-0.05) Weigh the above-mentioned raw materials; carbon source is weighed according to the total mass ratio of raw materials of 5%-30%.

[0026] (2) Solution preparation: Add ferric nitrate nonahydrate to deionized water to make a solution with an iron ion concentration of 0.5-2.0mol / L; add phosphoric acid to deionized water to make a solution with a mass concentration of 30-50%.

[0027] (3) Slurry preparation: fi...

Embodiment 1

[0033] 1212.0g ferric nitrate nonahydrate was made into a solution of 1.0mol / L, and 345.9g of phosphoric acid was made into a solution with a concentration of 50%. Add ferric nitrate solution and phosphoric acid solution into deionized water and stir for 4 hours, control system pH to 2.0 and temperature to 45° C. to obtain ferric phosphate suspension. Then, 110.7 g of lithium carbonate and 68.2 g of glucose were added to the suspension, and ground in a vertical stirring mill for 10 hours to obtain a mixed slurry. The mixed slurry was spray-dried with an inlet temperature of 180° C., an outlet temperature of 79° C., and a flow rate of the mixed slurry of 15 ml / min to obtain spherical precursor particles. Precursors in high-purity N 2 Calcined under air atmosphere, the temperature was first raised to 300 ° C for 5 hours, and then the temperature was raised to 750 ° C for 12 hours to obtain spherical LiFePO 4 / C composite powder.

[0034] The battery performance tests of the o...

Embodiment 2

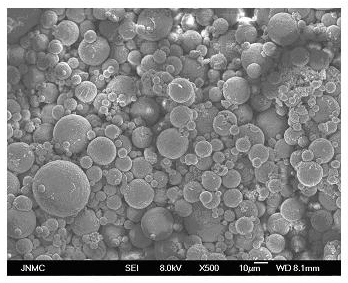

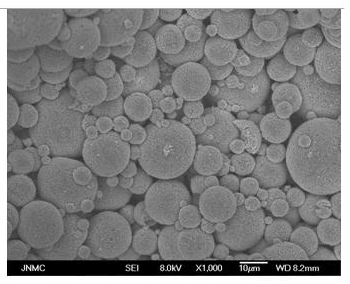

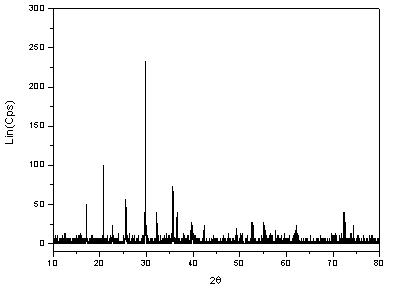

[0036]1212.0g ferric nitrate nonahydrate was made into a solution of 1.0mol / L, and 345.9g of phosphoric acid was made into a solution with a concentration of 50%. Add ferric nitrate solution and phosphoric acid solution into deionized water and stir for 4 hours, control the pH value of the system to 2.0, and the temperature to 55° C. to obtain ferric phosphate suspension. Then, 108.9 g of lithium carbonate, 8.9 g of magnesium oxalate and 68.2 g of glucose were added to the suspension, and ground in a vertical stirring mill for 10 hours to obtain a mixed slurry. The mixed slurry was spray-dried, the inlet temperature was 180°C, the outlet temperature was 80°C, and the flow rate of the mixed slurry was 15ml / min to obtain spherical precursor particles (see the attached figure 1 ). The precursor was calcined in a high-purity nitrogen atmosphere, and the temperature was first raised to 300°C for 5 hours, and then heated to 750°C for 12 hours to obtain spherical magnesium-doped Li ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com