Preparation technology of butadiene catalyst by oxidative dehydrogenation of butene

A technology of oxidative dehydrogenation and production process, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, organic chemistry, etc., and can solve the problem of high catalyst consumption, poor mechanical strength, system blockage, etc. problems, to achieve the effect of simple preparation process, improve mechanical strength and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

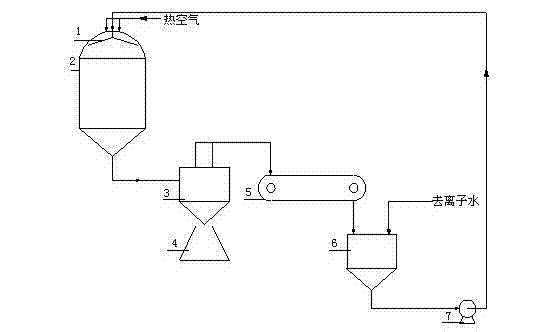

Image

Examples

Embodiment 1

[0031] Add the dilute nitric acid solution into a container with iron sheets, react at 50°C for 1 hour, then raise the temperature to 100°C in 15 minutes, and keep the temperature for 30 minutes to obtain a ferric nitrate solution with a mass fraction of 28%; add calcium chloride and zinc oxide Mixed aqueous solution with calcium hydroxide, wherein, the mol ratio of calcium chloride and iron is 14:500, and the mol ratio of calcium hydroxide and iron is 23:500, and the mol ratio of zinc oxide and iron is 125:500; Then use Ammonia water is used as a precipitating agent, and the ammonia water is added dropwise at a rate of 250ml / h until the pH of the solution is 8.3-8.4 to make the solution gel. The colloid after the precipitation will be added 0.5% kale powder binding agent and 0.5% gac (in terms of total weight of iron, calcium chloride, calcium hydroxide and zinc oxide); Aging at ℃ for 10 min, cooling to room temperature, filtering and washing with 40 ℃ ionized water, when th...

Embodiment 2

[0034] Add the dilute nitric acid solution into the container with the iron sheet, react at 55°C for 1.3h, then raise the temperature to 102°C over 20min, and keep the temperature constant for 45min to obtain a ferric nitrate solution with a mass fraction of 30%; add calcium chloride solution, A mixed aqueous solution of zinc oxide and calcium hydroxide, wherein the molar ratio of calcium chloride to iron is 14:500, the molar ratio of calcium hydroxide to iron is 25:500, and the molar ratio of zinc oxide to iron is 250:500; Then use ammonia water as a precipitant, add ammonia water dropwise at a rate of 500ml / h until the pH of the solution is 8.3 to 8.4, and make the solution colloidal; add the colloid after precipitation to 1% scallop powder and 0.5% methyl Cellulose mixture (based on the total weight of iron, calcium chloride, calcium hydroxide and zinc oxide) with the addition of 1% activated carbon (based on the total weight of iron, calcium chloride, calcium hydroxide and ...

Embodiment 3

[0037] Add the dilute nitric acid solution into a container with iron sheets, react at 60°C for 1.5h, then raise the temperature to 105°C in 30min, and keep the temperature constant for 60min to obtain a ferric nitrate solution with a mass fraction of 32%, add calcium chloride, oxidize A mixed aqueous solution of zinc and calcium hydroxide, wherein the molar ratio of calcium chloride to iron is 15:500, the molar ratio of calcium hydroxide to iron is 27:500, and the molar ratio of zinc oxide to iron is 375:500; then Use ammonia water as a precipitant, add ammonia water dropwise at a rate of 750ml / h until the pH of the solution is 8.3-8.4 to make the solution colloidal; add the colloid after precipitation with 2% scallop powder and 1% polyvinyl alcohol Mixture (based on the combined weight of iron, calcium chloride, calcium hydroxide and zinc oxide) with the addition of 2% activated carbon (based on the combined weight of iron, calcium chloride, calcium hydroxide and zinc oxide);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com