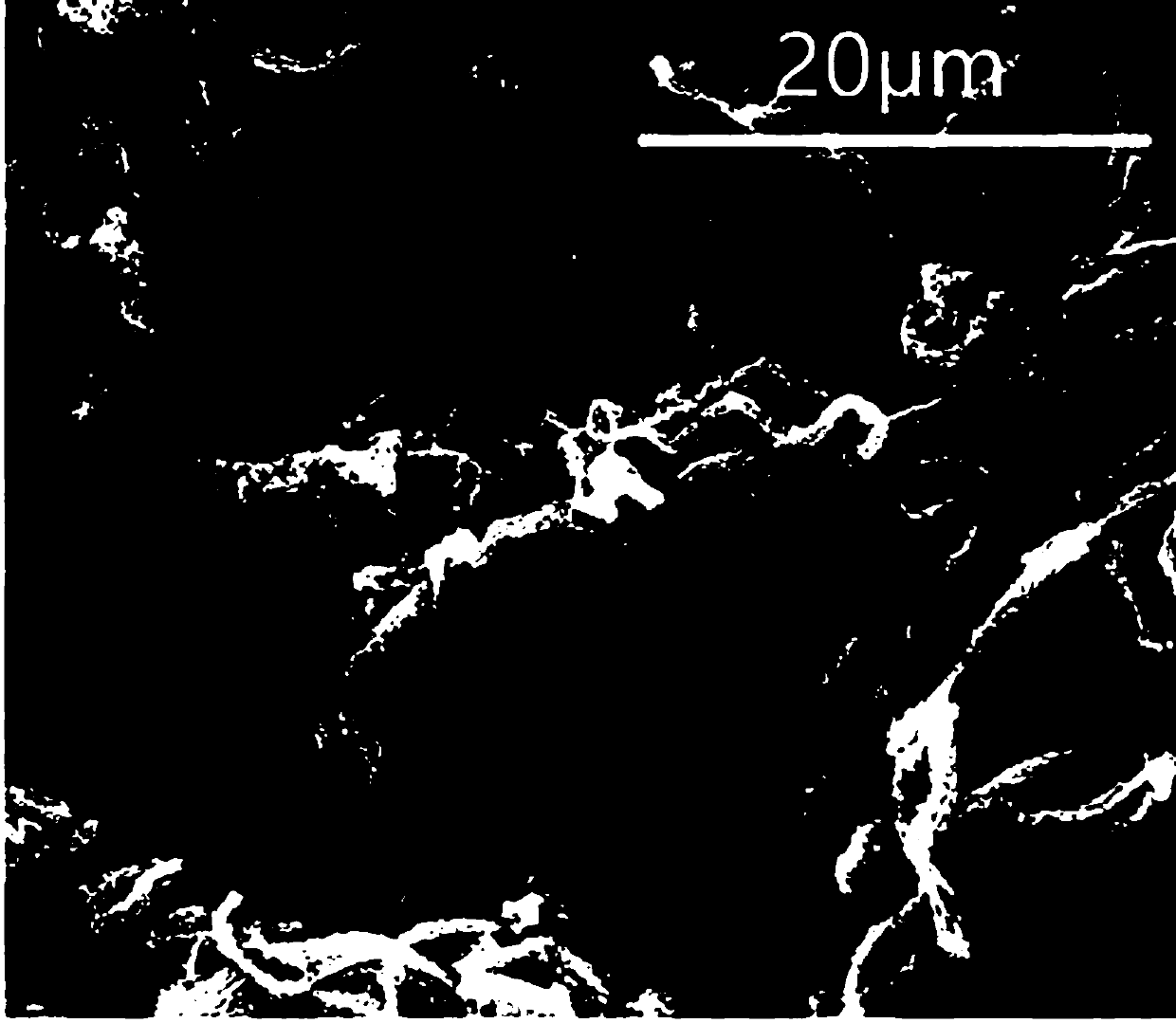

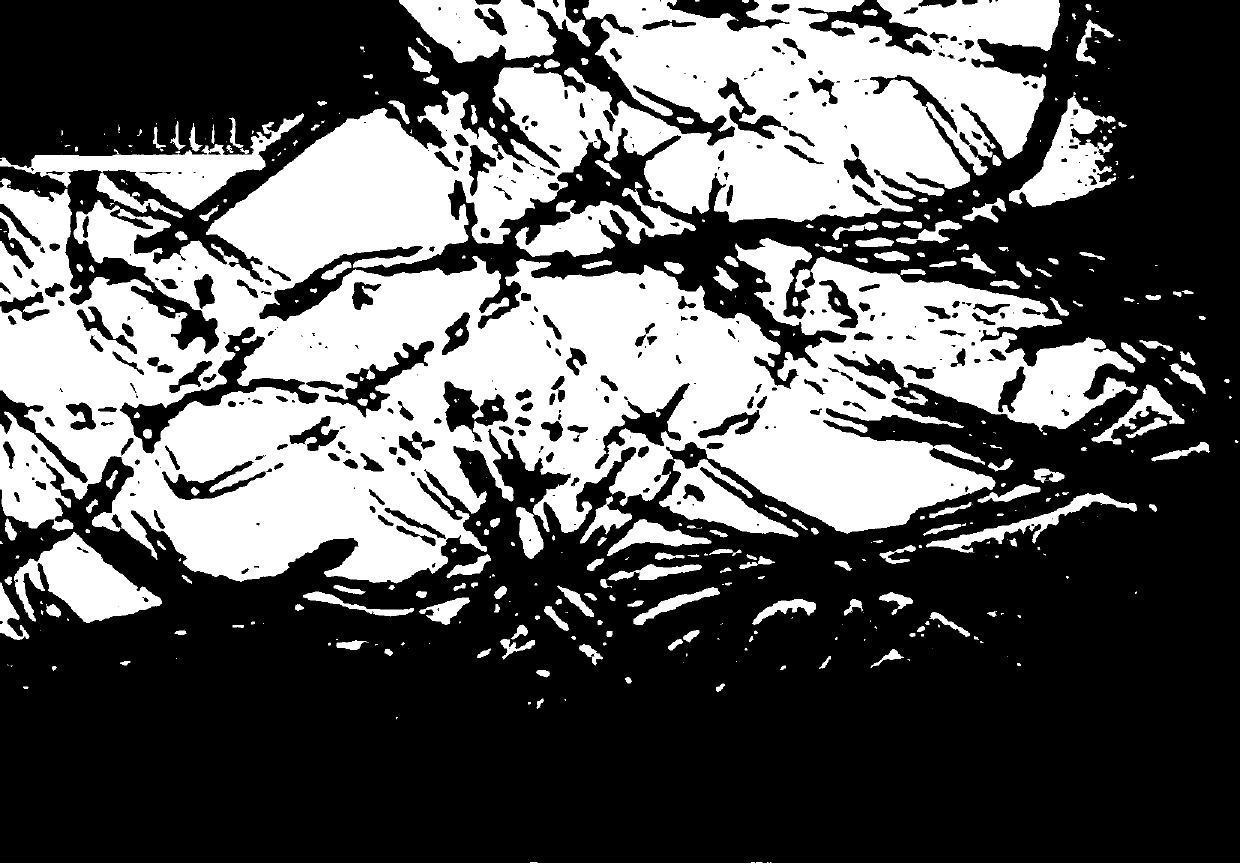

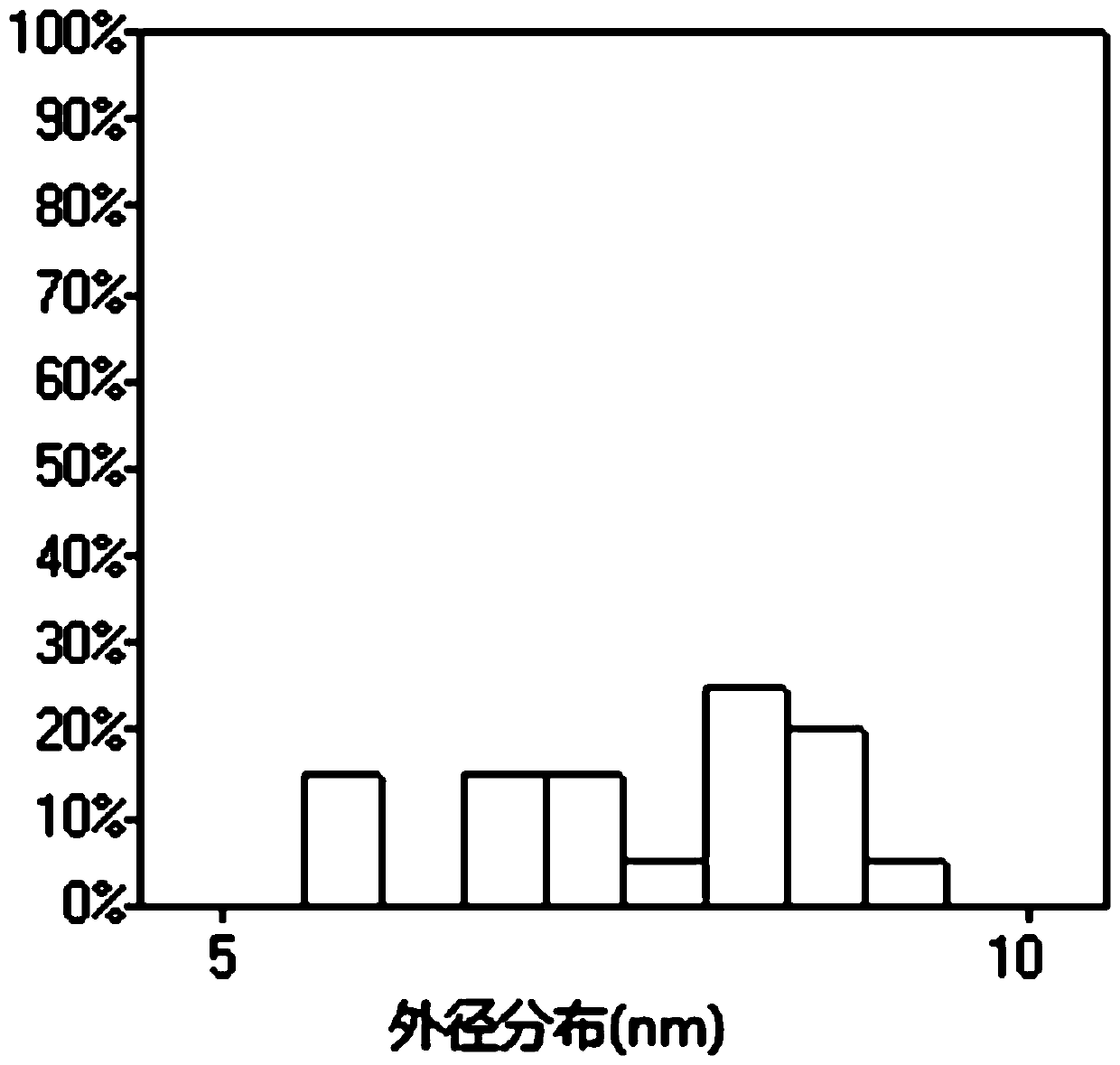

High-magnification carbon nanotubes having ultrafine tube diameter and prepared by two-stage method, catalyst and preparation method of catalyst

A carbon nanotube and high-magnification technology, which is applied to the preparation of carbon nanotubes with high-magnification ultra-fine diameters by a two-stage method, as well as the catalyst and preparation fields thereof, and can solve the problem that high-magnification and ultra-fine diameter carbon nanotubes cannot be prepared at the same time. , to achieve the effect of being conducive to industrialized large-scale production, the process is simple, and the quantity is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The catalyst that can prepare ultra-fine diameter carbon nanotubes proposed by the present invention is prepared from the following raw materials in parts by mass:

[0047] Active metal dispersed phase: cobalt nitrate 14.6-25.9, ammonium molybdate 0.9-2.7, iron nitrate 0-10.9, nickel nitrate 0-8.4;

[0048] Carrier metal continuous phase: aluminum nitrate 30.9~54.6, magnesium nitrate 25.4~45.3;

[0049] Complexing agent: 15.2~22.6;

[0050] The complexing agent is at least one of citric acid and ethylenediaminetetraacetic acid.

[0051] Among them, cobalt nitrate is cobalt nitrate hexahydrate with a purity of more than 99.0%; ammonium molybdate is ammonium molybdate tetrahydrate with a purity of 99.0%; iron nitrate is iron nitrate nonahydrate with a purity of more than 99.0%; nickel nitrate is nickel nitrate hexahydrate , the purity is more than 99.0%; aluminum nitrate is aluminum nitrate nonahydrate, the purity is more than 99.0%; magnesium nitrate is magnesium nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com