SBA-15 loaded iron-cobalt oxide catalyst, preparation method and application thereof in wastewater treatment

A technology of oxides and catalysts, which is applied in the field of SBA-15 supported metal oxide catalysts, can solve problems such as catalyst deactivation, and achieve the effects of low metal ion dissolution, high catalytic activity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of SBA-15: Dissolve 12 g of triblock copolymer P123 in 360 g of deionized water, add 15.6 mL of 37% (mass concentration) HCl, control the solution temperature between 35 and 38 °C, and wait for triblock copolymer P123 After stirring and dissolving, 15.5mL TEOS was added dropwise, stirred at a solution temperature of 38°C for 24 hours, then the obtained sample was placed in an autoclave, and the autoclave was placed in an oven at a temperature of 100°C for 24 hours. After the autoclave was cooled, the solid sample was obtained by suction filtration, dried at 80°C for 12 hours, and the obtained solid was calcined at 550°C for 4 hours (the heating program was 1°C / min) to obtain SBA-15.

[0032] Preparation of SBA-15 loaded iron oxide (5% iron oxide loading):

[0033] Preparation of SBA-15 loaded iron oxide (the iron oxide load is 5%): add 0.12g aminoacetic acid to the salt solution containing 0.25g ferric nitrate nonahydrate, stir and mix; add 1g SBA-15, stir a...

Embodiment 2

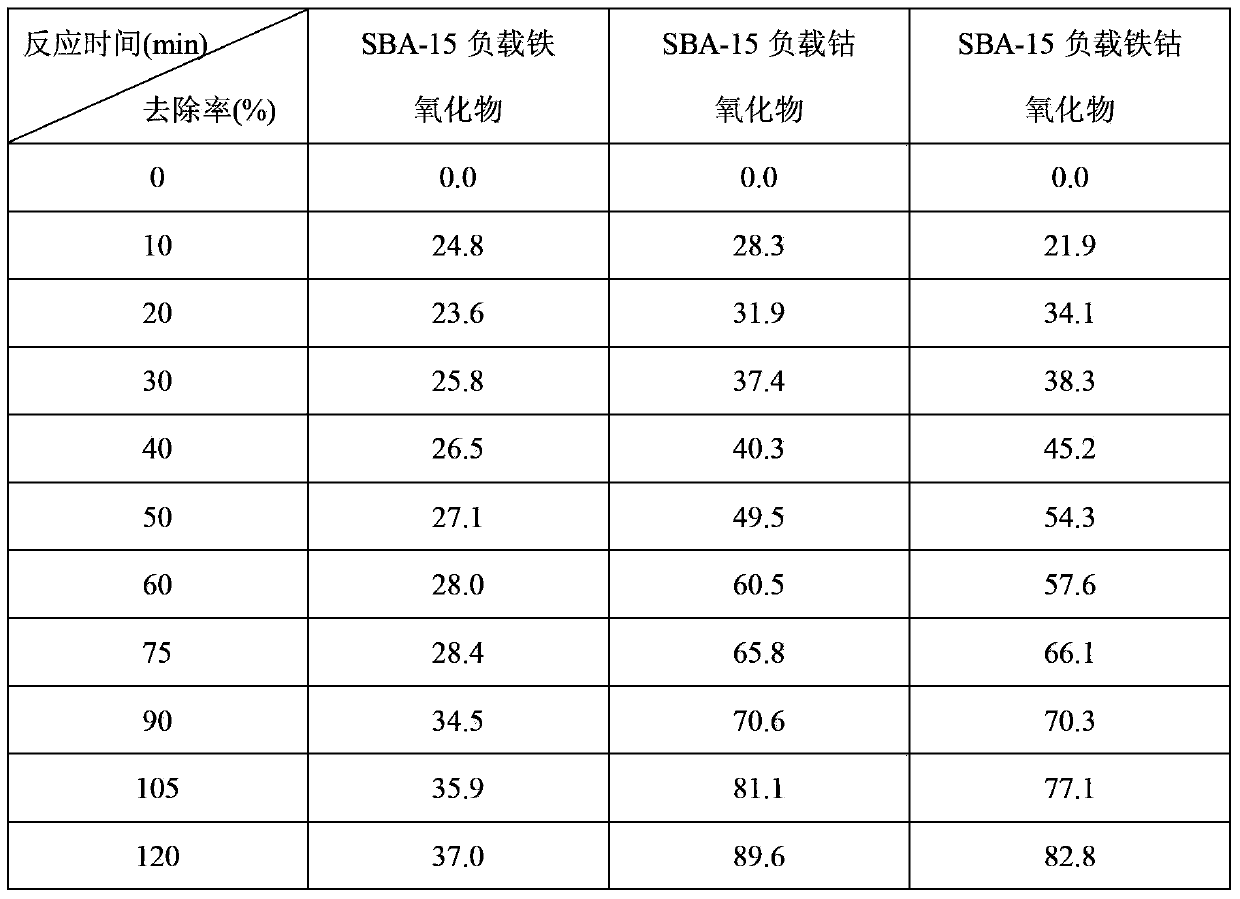

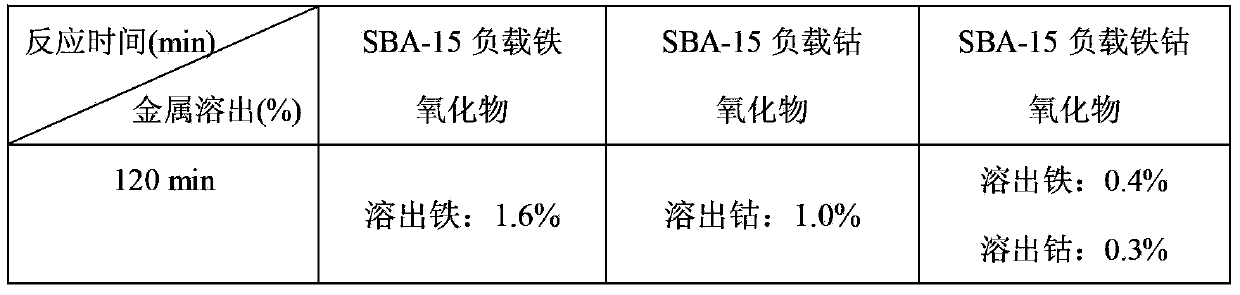

[0045] Ultrasonic / heterogeneous activation of persulfate system: add 0.2g of persulfate (2KHSO 5 ·KHSO 4 ·K 2 SO 4 ), then add the SBA-15 loaded iron oxide (the iron oxide loading is 5%), the SBA-15 loaded cobalt oxide (the cobalt oxide loading is 5%), the SBA-15 loaded iron oxide in Example 1 Iron cobalt oxide 0.1g (the load of iron cobalt oxide is 5%, Fe:Co=1:1), ultrasonic power 200W, reaction at room temperature for 120min, after passing through a 0.22μm filter membrane, measure the absorbance, and measure three kinds The results of the catalyst's removal rate of orange II and the dissolution rate of metal ions in the solution after the reaction are shown in Table 1 and Table 2.

[0046] Table 1 The decolorization effect of different catalysts on orange Ⅱ under ultrasonic conditions

[0047]

[0048] Table 2 The dissolution rate of metal ions of different catalysts under ultrasonic conditions

[0049]

[0050] It can be seen from Table 1 that after 120 minutes o...

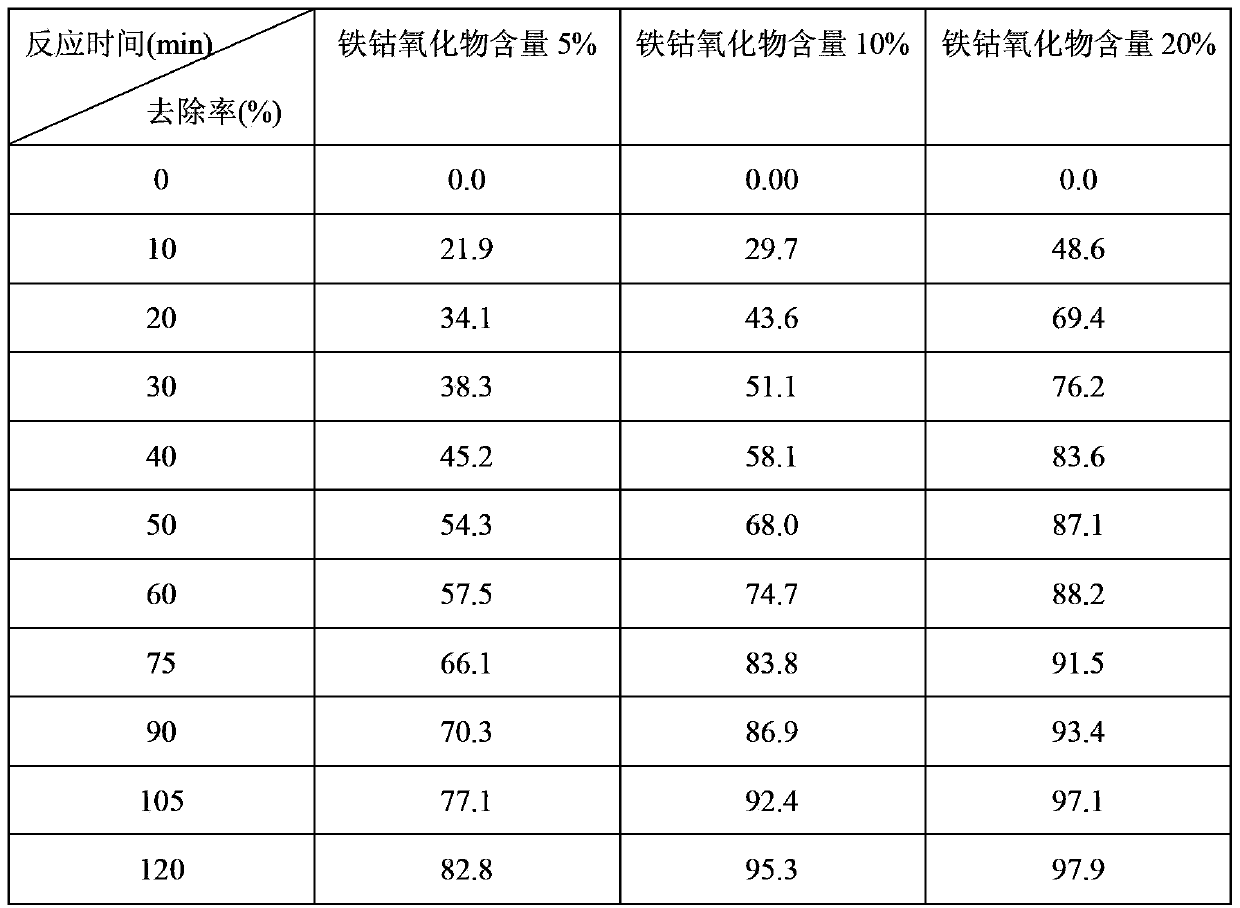

Embodiment 1)

[0052] Under the condition of Fe:Co=1:1, the SBA-15 supported iron-cobalt oxide catalyst with 5% iron-cobalt oxide content, 10% iron-cobalt oxide content and 20% iron-cobalt oxide content (three kinds of catalysts were prepared) See Example 1 for details of the preparation, according to Example 2, the removal rate of orange II by SBA-15 loaded iron cobalt oxide catalyst under ultrasonic / heterogeneous activation of persulfate system was determined, and the results are shown in Table 3 .

[0053] Table 3 The decolorization effect of catalysts with different metal oxide loadings on orange Ⅱ under ultrasonic conditions

[0054]

[0055] It can be seen from the above table that after 120 minutes of reaction, the removal effects of SBA-15 loaded iron-cobalt oxide 5%, 10%, and 20% catalysts (Fe:Co=1:1) on orange II were 82.8%, 95.3%, and 97.9%, respectively. %, a higher removal rate can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com