Soft and hard double template method for preparing three-dimensional ordered macroporous iron oxide with mesoporous pore wall

A three-dimensional ordered, iron oxide technology, used in iron oxide, iron oxide/iron hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

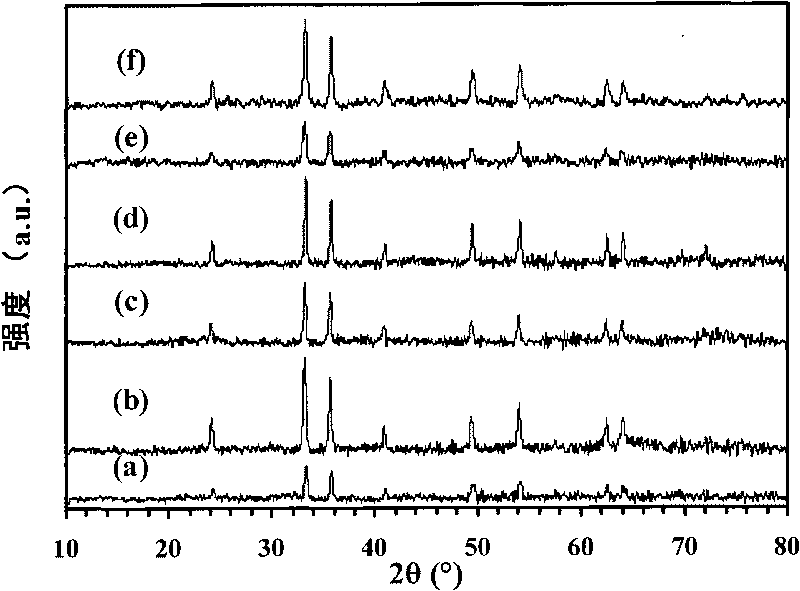

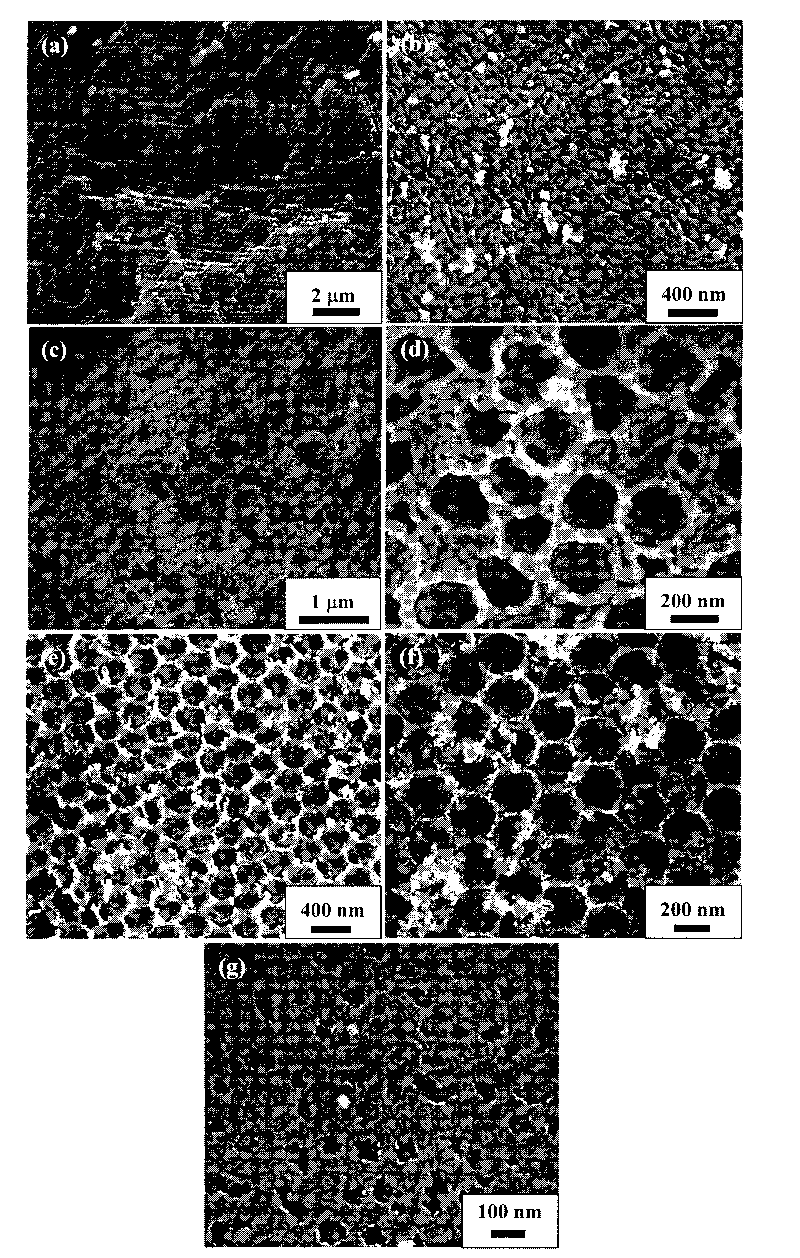

[0013] Example 1: At normal temperature (25°C), normal pressure (1atm) and ultrasonic conditions (90HZ), 10mmolFe(NO 3 ) 3 9H 2 O was dissolved in 10 mL of absolute ethanol, and after being mixed evenly, it was added dropwise to a Buchner funnel equipped with 2 g of PMMA microspheres arranged in a close-packed arrangement. After the PMMA microspheres were completely infiltrated, suction filtration was performed to remove excess liquid, and then Dry at room temperature with a relative humidity lower than 50% for 12 hours, and finally put the obtained powder into a muffle furnace, raise the temperature from room temperature to 300°C at a rate of 1°C / min and keep the temperature constant for 3 hours, then rise to 650°C and keep the temperature constant After 3 hours, a disordered porous iron oxide with a rhombohedral crystal structure is obtained, with a pore diameter of 30-120 nm.

Embodiment 2

[0014] Example 2: At normal temperature (25°C), normal pressure (1atm) and ultrasonic conditions (90HZ), 25mmolFe(NO 3 ) 3 9H 2 O was dissolved in 10mL of anhydrous methanol and 15mL of anhydrous ethylene glycol (the volume ratio of methanol and ethylene glycol was 2:3), and after being mixed evenly, it was added dropwise to a Brookfield container equipped with 2 g of close-packed PMMA microspheres. In the funnel, after the PMMA microspheres are completely infiltrated, perform suction filtration to remove excess liquid, then dry at room temperature with a relative humidity below 50% for 12 hours, and finally put the obtained powder into a muffle furnace at 1°C / min The heating rate is raised from room temperature to 300°C and kept at a constant temperature for 3 hours, and then raised to 650°C and kept at a constant temperature for 3 hours to obtain macroporous iron oxide with a rhombohedral crystal structure and a certain degree of order, with a macropore diameter of 180-230n...

Embodiment 3

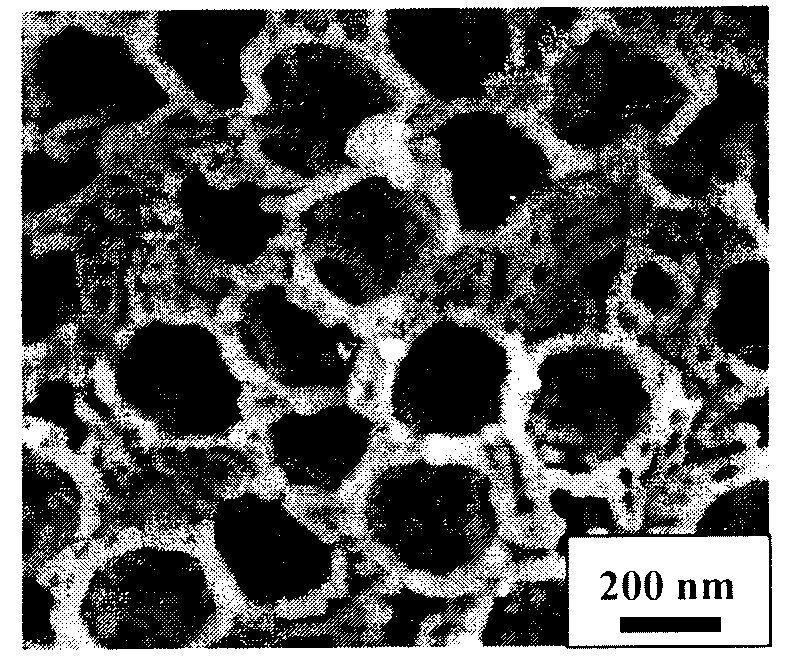

[0015] Example 3: At normal temperature (25°C), normal pressure (1atm) and ultrasonic conditions (90HZ), 1g P123 and 10mmol Fe(NO 3 ) 3 9H 2 O was dissolved in 10 mL of absolute ethanol, and after being mixed evenly, it was added dropwise to a Buchner funnel equipped with 2 g of PMMA microspheres arranged in a close-packed arrangement. After the PMMA microspheres were completely infiltrated, suction filtration was performed to remove excess liquid, and then Dry at room temperature with a relative humidity lower than 50% for 24 hours, and finally put the obtained powder into a muffle furnace, raise the temperature from room temperature to 300°C at a rate of 1°C / min and keep the temperature constant for 3 hours, then rise to 500°C and keep the temperature constant After 3 hours, three-dimensional ordered macroporous iron oxide with a rhombohedral crystal structure is obtained, the diameter of the macropores is 250-280 nm, and the diameter of the pore walls is 20-50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com