Preparation method of clay-perovskite composite material and application thereof

A composite material and perovskite technology is applied in the application field of photocatalytic degradation of antibiotics to achieve the effects of increasing lattice defects, uniform dispersion and favorable catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First weigh 0.214g of lanthanum nitrate, 0.07146g of cerium nitrate, and dissolve 0.33g of ferric nitrate in 100ml of deionized water, then add 0.336g of complexing agent citric acid, and finally add 1g of halloysite, and stir for 2h to obtain Mix the solution, then place it in a water bath at 70°C for 18 hours, evaporate the water to obtain a wet gel, dry it in a drying oven at 80°C, and when the wet gel becomes a dry gel, place it in a muffle furnace at 550°C , calcined at 1° C. / min, and finally ground to obtain a cerium-doped lanthanum ferrite / halloysite nanostructure composite material with a loading of 20 wt%.

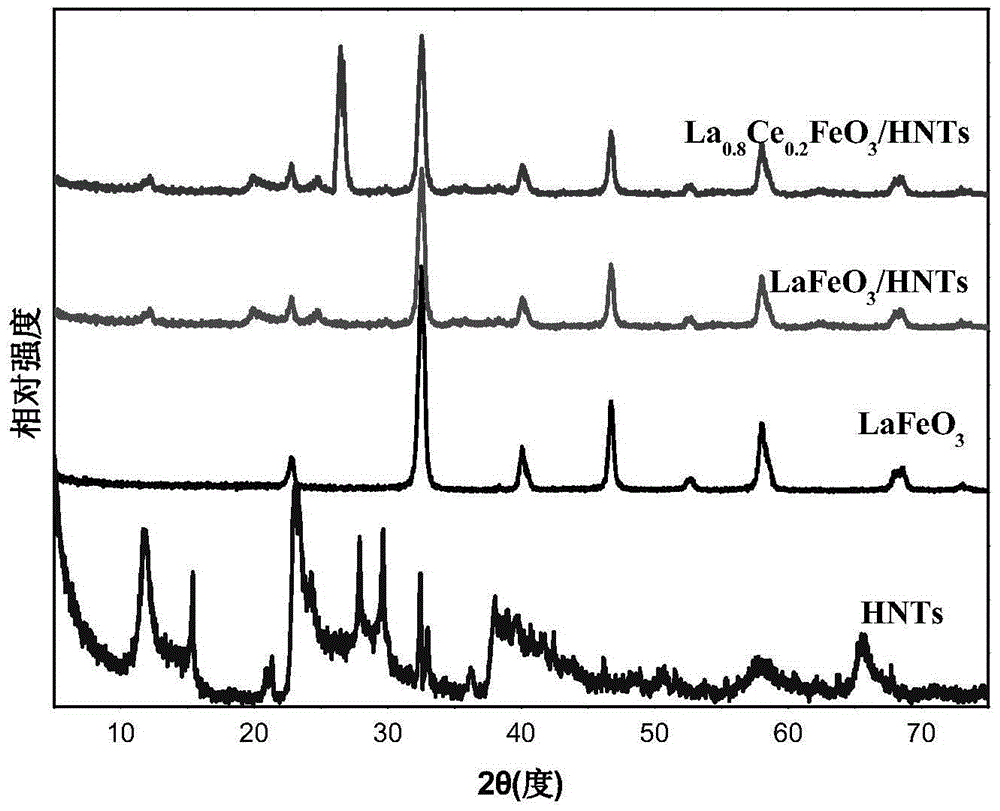

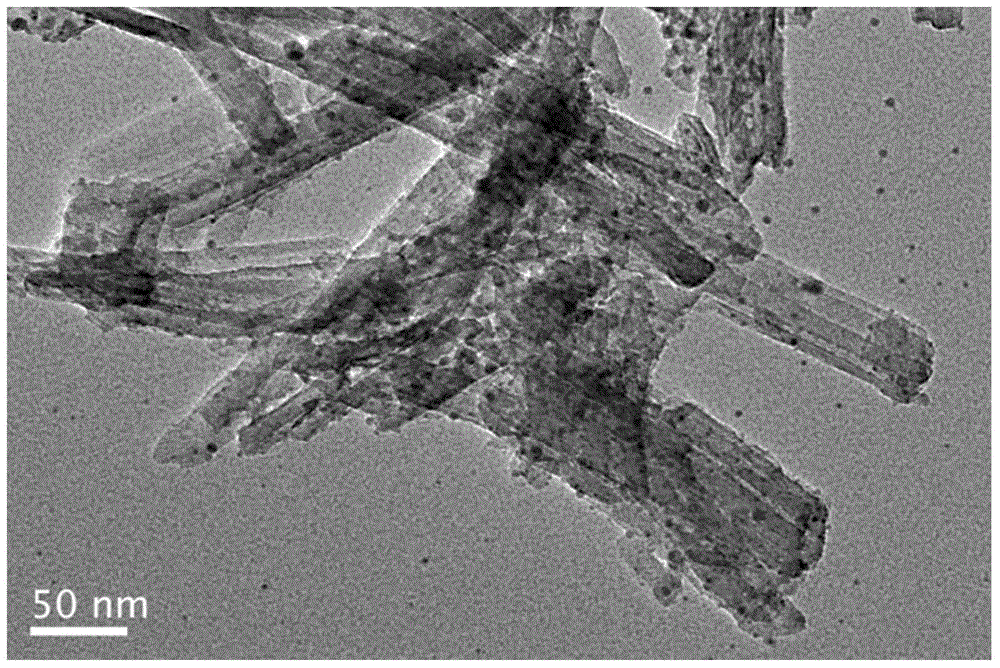

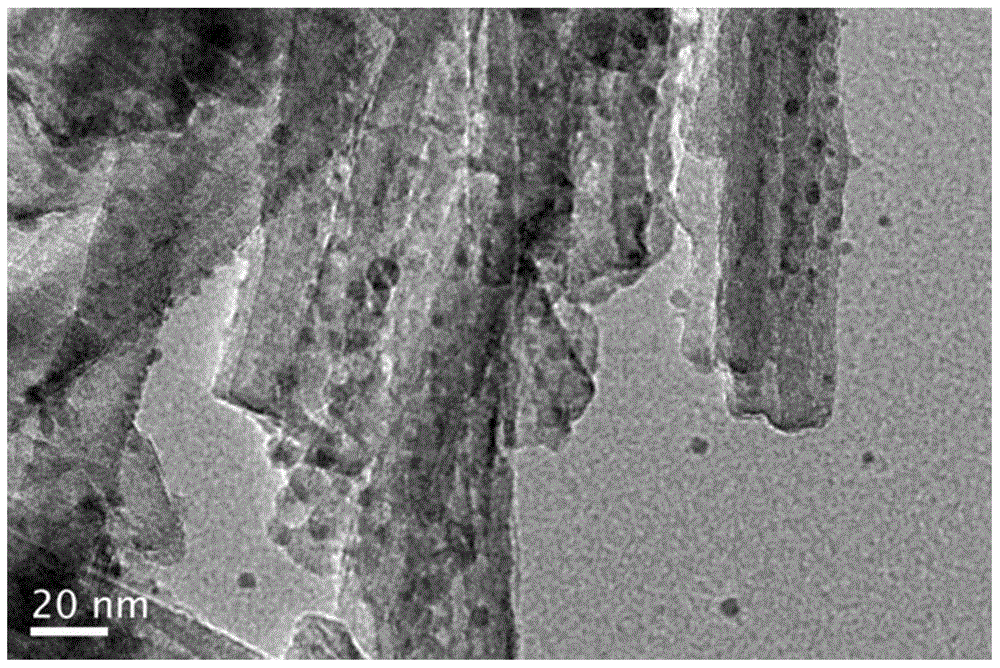

[0024] Carry out X-ray powder diffraction experiment to the above-mentioned sample of gained, and observe its morphology and structure under the transmission electron microscope, the lanthanum ferrite / halloysite nanostructure composite material and The XRD patterns of lanthanum ferrite, halloysite, and lanthanum ferrite / halloysite nanostructure composites a...

Embodiment 2

[0029] First weigh 0.211g of lanthanum nitrate and 0.234g, and dissolve 0.11g of cerium nitrate and ferric nitrate in 100ml of deionized water, then add 0.168g of complexing agent citric acid, and finally add 1g of halloysite, and stir for 2h to obtain Mix the solution, then place it in a water bath at 70°C for 18 hours, evaporate the water to obtain a wet gel, dry it in a drying oven at 80°C, and when the wet gel becomes a dry gel, place it in a muffle furnace at 550°C , calcined at 1° C. / min, and finally ground to obtain a cerium-doped lanthanum ferrite / halloysite nanostructure composite material with a loading of 20 wt %. The subsequent detection is as in Example 1.

Embodiment 3

[0031] First weigh 0.166g of lanthanum nitrate and 0.211g, 0.21g of cerium nitrate, ferric nitrate dissolved in 100ml of deionized water, then add 0.168g of complexing agent citric acid, finally add 1g of halloysite, stir for 2h to obtain Mix the solution, then place it in a water bath at 70°C for 18 hours, evaporate the water to obtain a wet gel, dry it in a drying oven at 80°C, and when the wet gel becomes a dry gel, place it in a muffle furnace at 550°C , calcined at 1° C. / min, and finally ground to obtain a cerium-doped lanthanum ferrite / halloysite nanostructure composite material with a loading of 20 wt %. The subsequent detection is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com