Preparation method of BiFeO3 material, BiFeO3/TiO2 composite film and application thereof

A composite film and film layer technology, applied in chemical instruments and methods, iron compounds, chemical/physical processes, etc., can solve the problems of side effects, inconvenient use, etc., achieve improved absorption rate, increase ferroelectric susceptibility, and facilitate large-scale The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

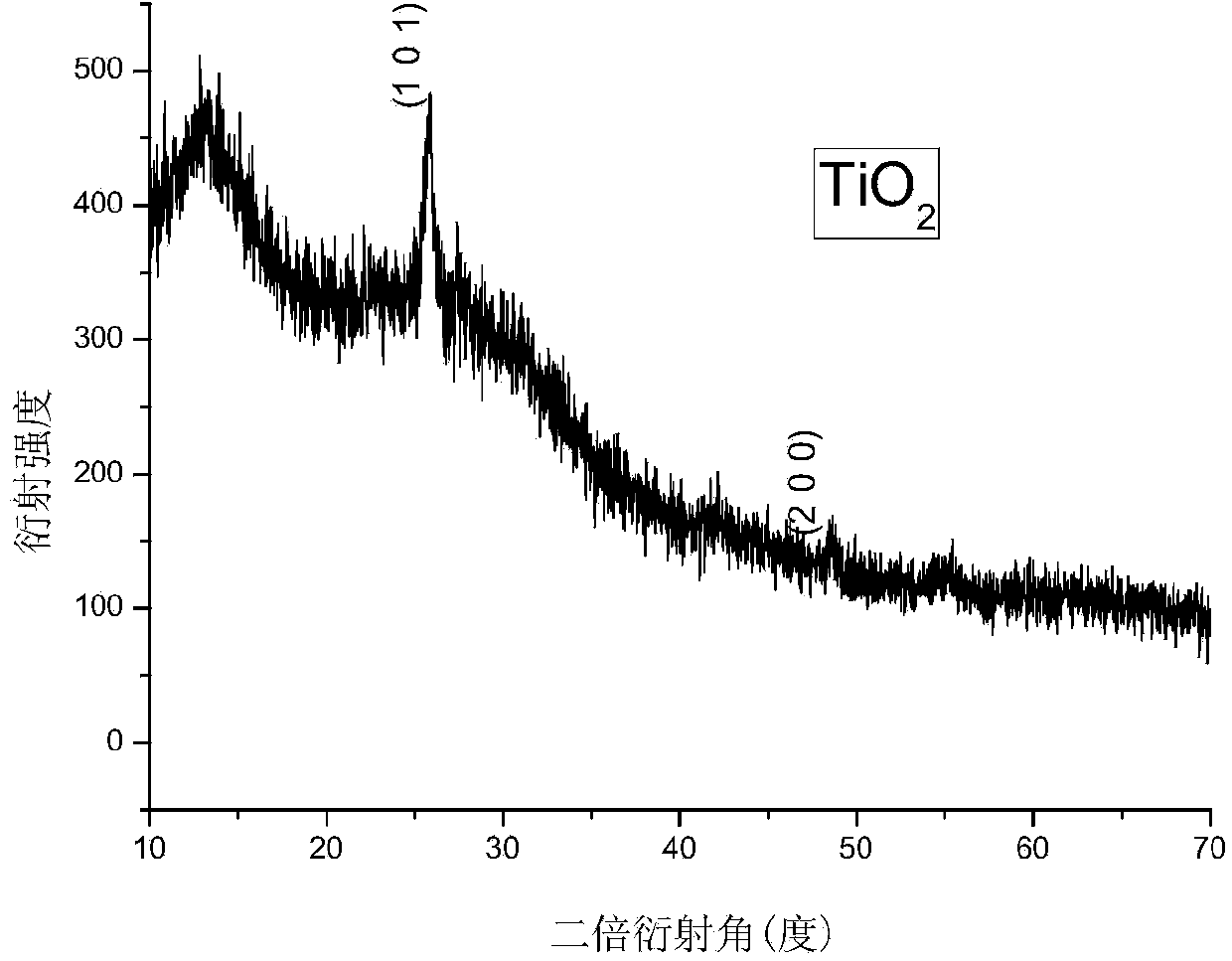

[0036] TiO of the present invention 2 The preparation method of the material is a conventional preparation method in the art.

[0037] The substrate of the present invention can be selected from substrate materials commonly used in the art, such as glass slides, LaAlO 3 , SrTiO 3 , silicon wafers, etc.

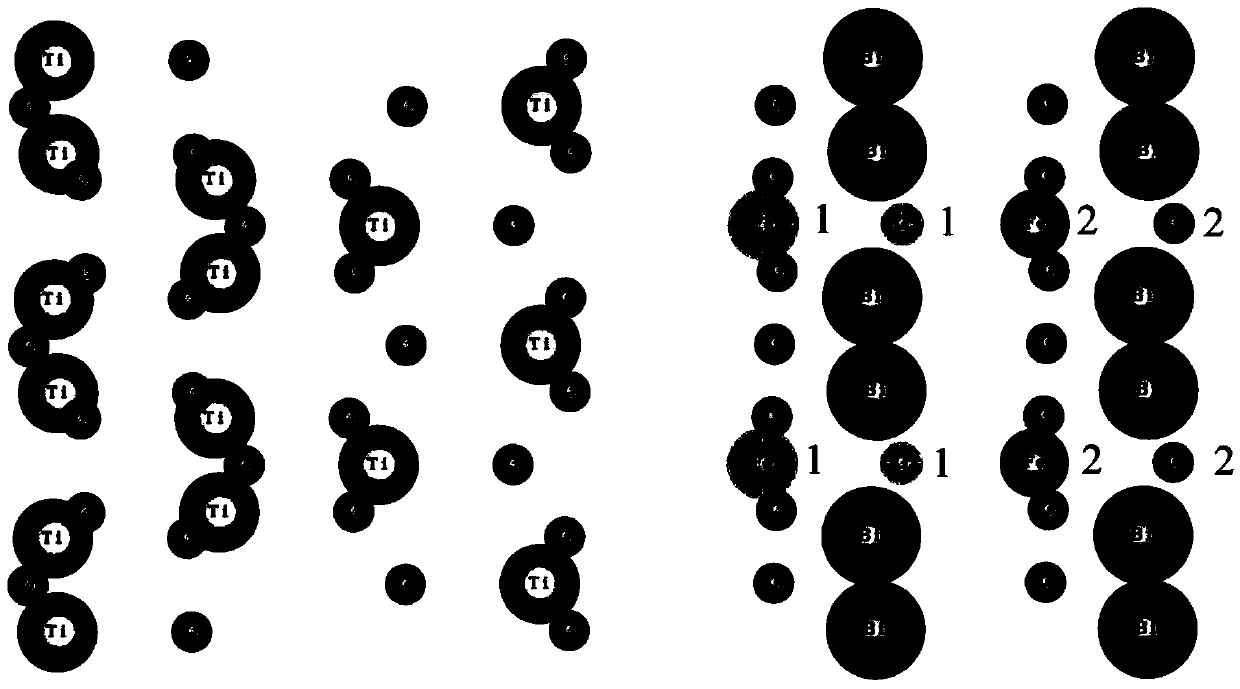

[0038] TiO of the present invention 2 / BFO double-layer film means that the substrate is first coated with TiO 2 thin film, the TiO 2 The film is coated with a bilayer film of BFO film.

[0039] BFO / TiO of the present invention 2 Double-layer film means that the substrate is first coated with a BFO film, and the BFO film is coated with TiO 2 The bilayer film of the film.

Embodiment 1

[0042] This example is about the preparation method of BFO sol.

[0043] (1) 3.0695g bismuth nitrate (Bi(NO 3 ) 3 ) and 2.3511g ferric nitrate (Fe(NO 3 ) 3 ) was dissolved in 20ml of ethylene glycol methyl ether to obtain solution 1, the concentration of which was 0.3mol / l;

[0044] (2) Add complexing agent citric acid to solution 1 to obtain solution 2. The dosage of citric acid is: the molar ratio of citric acid, bismuth ions and iron ions is: 1:1:1;

[0045] (3) Adjust the pH of solution 2 to 4 with acetic acid; obtain BFO sol after aging for 24 hours.

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is that the concentration of solution one is 0.2 mol / L, and the pH of solution two is 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com