Porous graphene, preparation method thereof, and supercapacitor

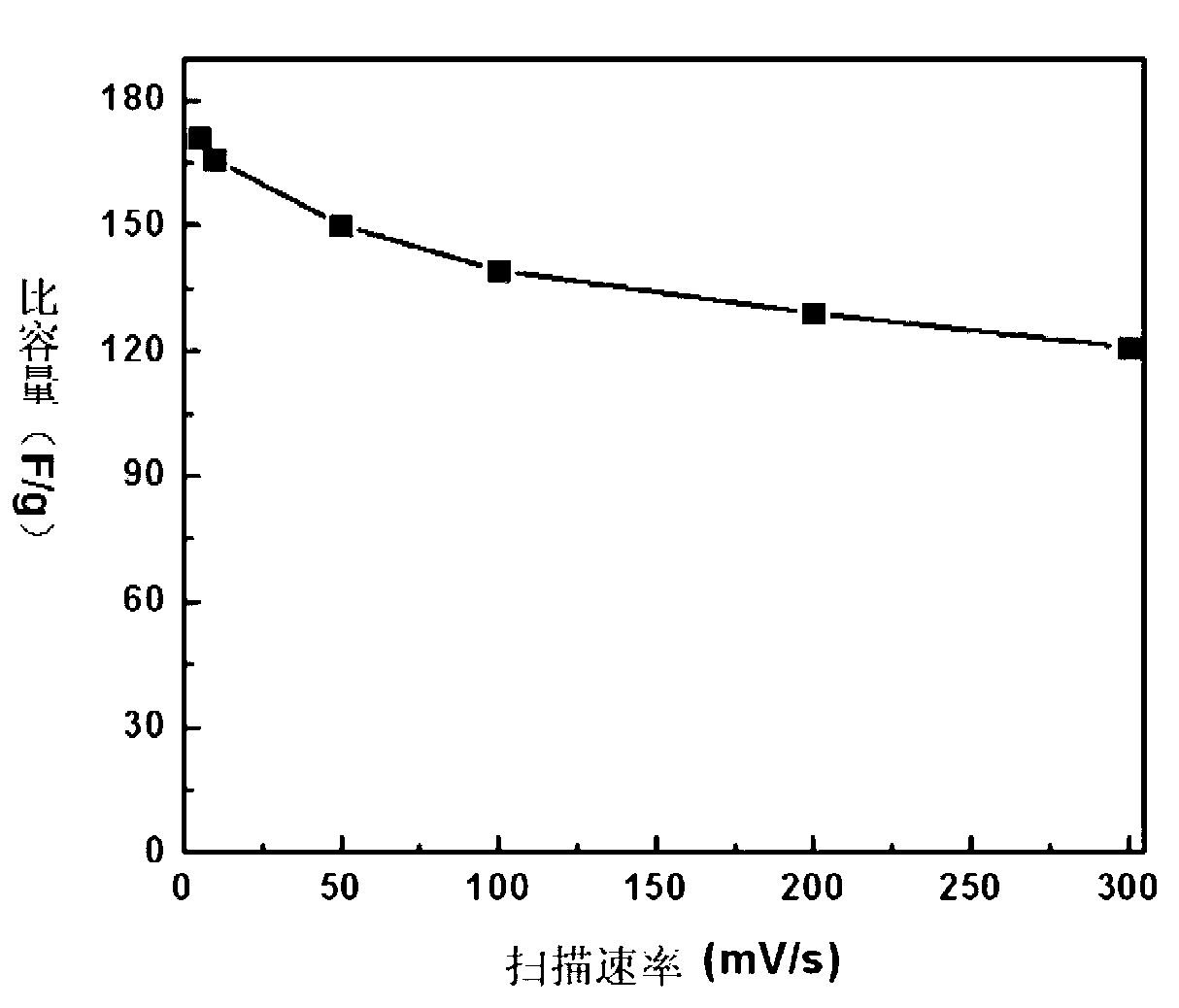

A porous graphene and graphene technology, applied in graphene, hybrid capacitor electrodes, nano-carbon, etc., can solve the problems of low tap density of graphene, induce electrolyte, limit commercial application, etc., and achieve high-rate charging Discharge performance, beneficial effect of adsorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

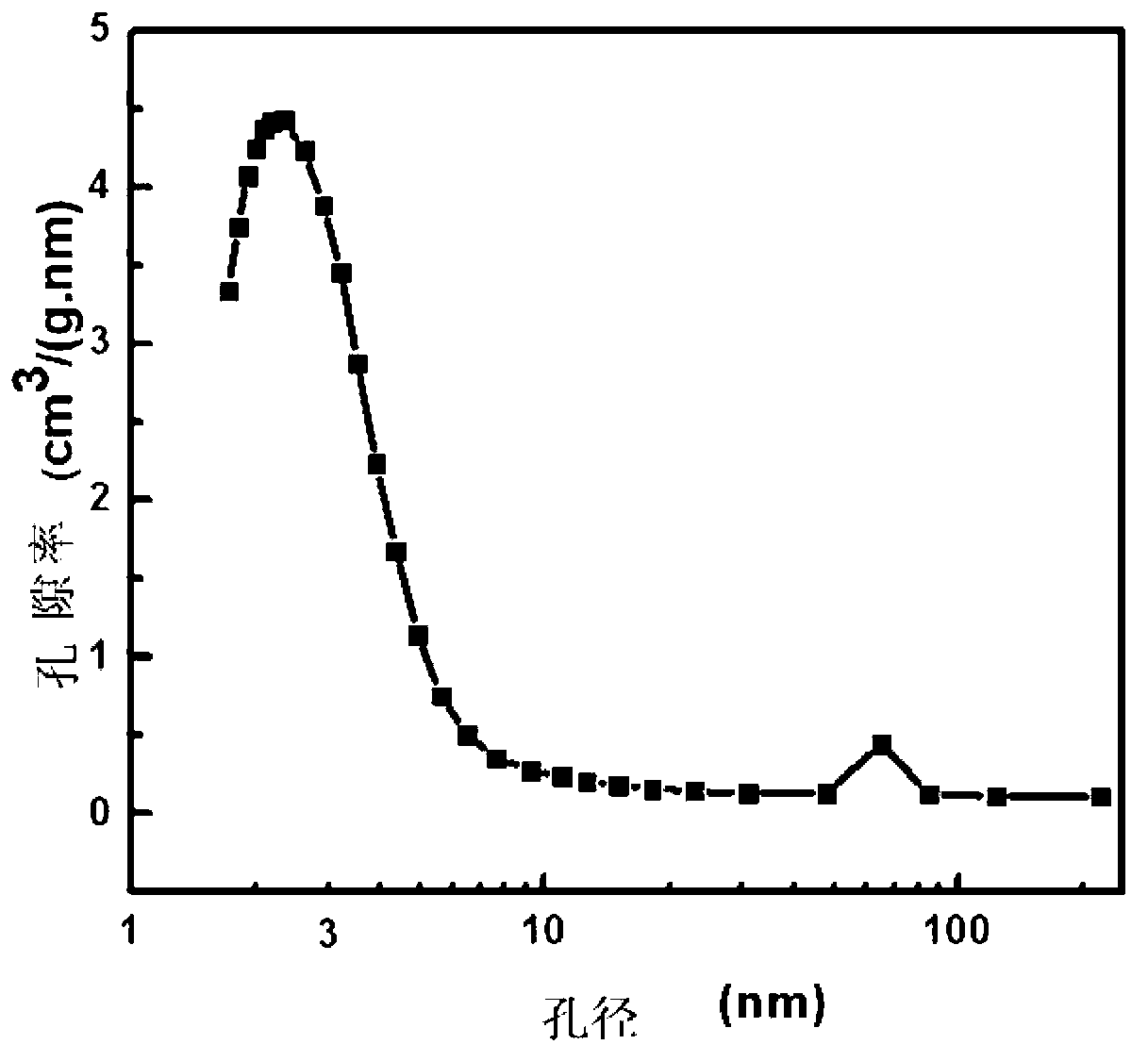

[0034] The present invention also provides a preparation method of the above-mentioned porous graphene, comprising the following steps: A) mixing two or more flake graphites of different sizes, and then oxidizing to obtain pre-oxidized graphite; B) mixing the pre-oxidized graphite After the expansion treatment, graphene is obtained; C) the graphene is mixed with the first activator, and heated at 400°C-800°C for 0.5-4h to make pores for the first time to obtain microporous graphene; D) the After the microporous graphene is treated with mixed acid, mixed with the second activator, and heated at 600° C. to 1000° C. for 5 to 48 hours to form pores for the second time, the porous graphene is obtained.

[0035] The sources of all raw materials in the present invention are not particularly limited, and they can be commercially available.

[0036] In the present invention, two or more flake graphites of different sizes are mixed, wherein the flake graphite is flake graphite well know...

Embodiment 1

[0053] 1.1 Mix flake graphite of 45 μm, 20 μm and 2 μm uniformly according to the mass ratio of 20:1:1 to obtain mixed graphite; take 5 g of mixed graphite, 87.5 ml of concentrated hydrochloric acid and 45 ml of concentrated nitric acid and mix evenly, then slowly add 45 g of potassium chlorate, React in a water bath at 60° C. for 24 hours, wash repeatedly with deionized water until the pH is neutral, and dry to obtain graphite oxide.

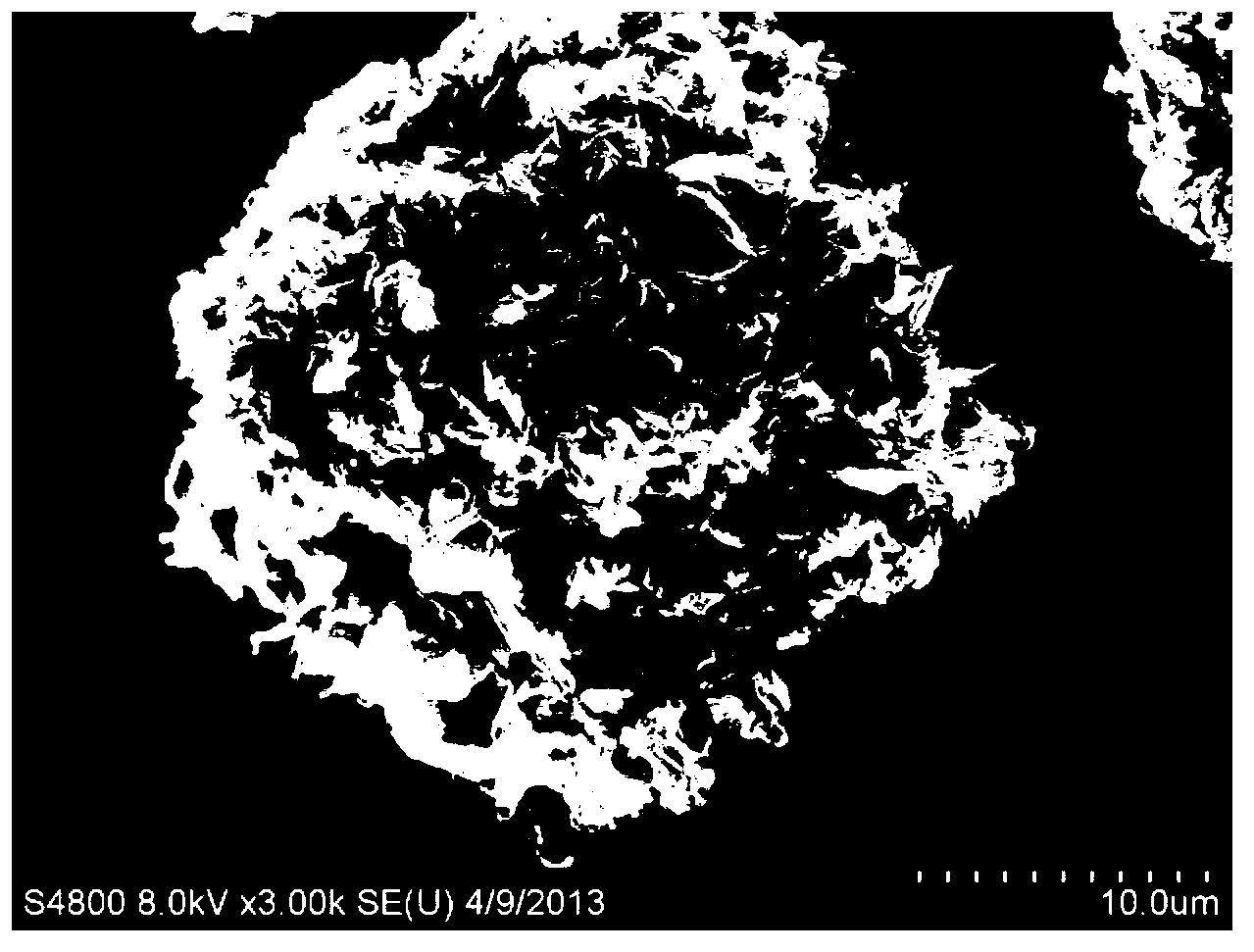

[0054] 1.2 The graphite oxide obtained in 1.1 was thermally expanded in a muffle furnace at 800°C for 30s to obtain graphene, which was formulated into a 0.5wt% aqueous solution at 100°C for spray drying to obtain spherical agglomerates of spherical graphene.

[0055] 1.3 Mix the spherical graphene and potassium hydroxide obtained in 1.2 uniformly in a mass ratio of 20:1, heat to 800°C for 0.5h in a tube furnace containing water vapor and nitrogen atmosphere, and obtain microporous graphene .

[0056] 1.4 Mix 5g of the microporous graphene obt...

Embodiment 2

[0066] 2.1 Mix flake graphite of 100 μm, 50 μm, 20 μm and 2 μm uniformly according to the mass ratio of 10:5:2:1 to obtain mixed graphite; take 1.5g of mixed graphite and 70ml of concentrated sulfuric acid and mix evenly, then slowly add 1.5g of nitric acid Potassium was reacted at room temperature for 2 hours, and 9 g of potassium permanganate was added thereto, reacted in a water bath at 40° C. for 6 hours, washed repeatedly with deionized water until the pH value was neutral, and dried to obtain graphite oxide.

[0067] 2.2 The graphite oxide obtained in 2.1 was thermally expanded in a muffle furnace at 1000° C. for 10 seconds to obtain graphene.

[0068] 2.3 Mix the graphene and potassium hydroxide obtained in 2.2 uniformly according to the mass ratio of 10:1, heat to 600 °C for 2 hours in a tube furnace containing water vapor and nitrogen atmosphere, and obtain microporous graphene, which Prepare a 0.8wt% aqueous solution and spray dry at 120°C to obtain spherical micropo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com