Grafted ceramic powder and preparation method thereof, ceramic diaphragm and preparation method thereof, lithium ion battery, battery module and battery pack

A lithium-ion battery, ceramic powder technology, applied in battery pack parts, secondary batteries, circuits, etc., can solve problems such as poor stability of ceramic separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The second aspect of the present invention provides a preparation method of grafted ceramic powder, comprising:

[0054] (1) mixing the ceramic powder with a dispersant to obtain a ceramic powder dispersion;

[0055] (2) Carrying out a grafting reaction between the grafted polyolefin and the ceramic powder dispersion, so that the grafted polyolefin is grafted on the surface of the ceramic powder;

[0056] (3) Filtering the reaction product obtained in step (2), washing and drying the obtained solid to obtain a grafted ceramic powder.

[0057] In the present invention, preferably, in step (1), the dispersant is selected from ethyl acetate, toluene, xylene, N,N-dimethylformamide, N,N-dimethylacetamide, dimethyl One or more of sulfoxide and nitrogen methylpyrrolidone.

[0058] In the present invention, preferably, in the ceramic powder dispersion, the solid content of the ceramic powder is 10-40wt%.

[0059] In the present invention, preferably, in step (2), the grafted...

Embodiment 1

[0115] Preparation of grafted ceramic powder:

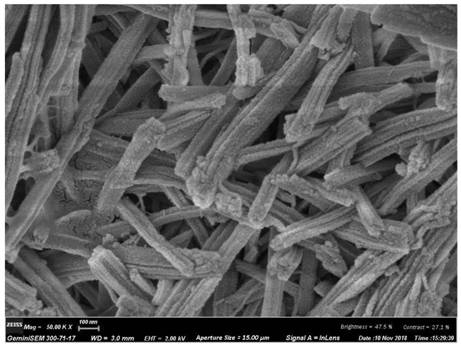

[0116] (1) 80g of rod-shaped alumina (one-dimensional nanomaterials, aspect ratio of about 80-100:1, diameter of about 300-500nm, curvature of about 30-40cm / m, first dried at 60°C for 24h) and 120g of two Toluene is mixed to obtain ceramic powder dispersion (solid content is 40wt%);

[0117] (2) Add 2g of maleic anhydride grafted polyethylene (the weight average molecular weight is about 15000, and the grafting rate is about 1.0wt%) into 200mL of xylene for ultrasonic dissolution (the amount of maleic anhydride grafted polyethylene is rod-shaped oxidation 0.1wt% of aluminum), and then carry out the grafting reaction with the ceramic powder dispersion for 30min under a water bath condition of 40°C;

[0118] (3) The reaction product obtained by the grafting reaction was centrifugally filtered, and the obtained solid was washed several times with ethanol, and dried at 120° C. for 8 hours to obtain grafted rod-shaped alumina, which ...

Embodiment 2

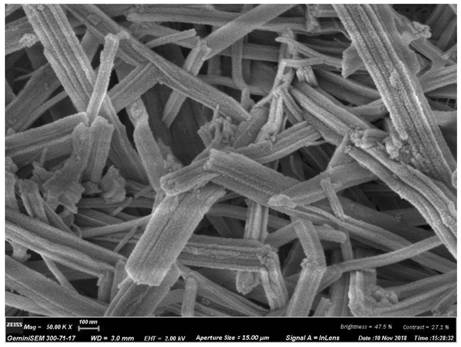

[0125] Preparation of grafted ceramic powder:

[0126] (1) 20g of rod-shaped alumina (one-dimensional nanomaterials, aspect ratio of about 4-20:1, diameter of about 20-100nm, curvature of about 1-10cm / m, first dried at 60°C for 8h) and 180g of N,N-dimethylformamide is mixed to obtain a ceramic powder dispersion (solid content is 10wt%);

[0127] (2) 2g maleic anhydride grafted polyethylene (the weight-average molecular weight is about 10000, and the grafting rate is about 1.3wt%) is added into 200 mL of N-methylpyrrolidone for ultrasonic dissolution (the consumption of maleic anhydride grafted polyethylene is 10wt% of rod-shaped alumina), and then carry out grafting reaction with the ceramic powder dispersion for 30min under a water bath condition of 60°C;

[0128] (3) The reaction product obtained by the grafting reaction was centrifugally filtered, and the obtained solid was washed several times with ethanol, and dried at 120° C. for 10 h to obtain grafted rod-shaped alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com