Porous graphene and preparation method thereof

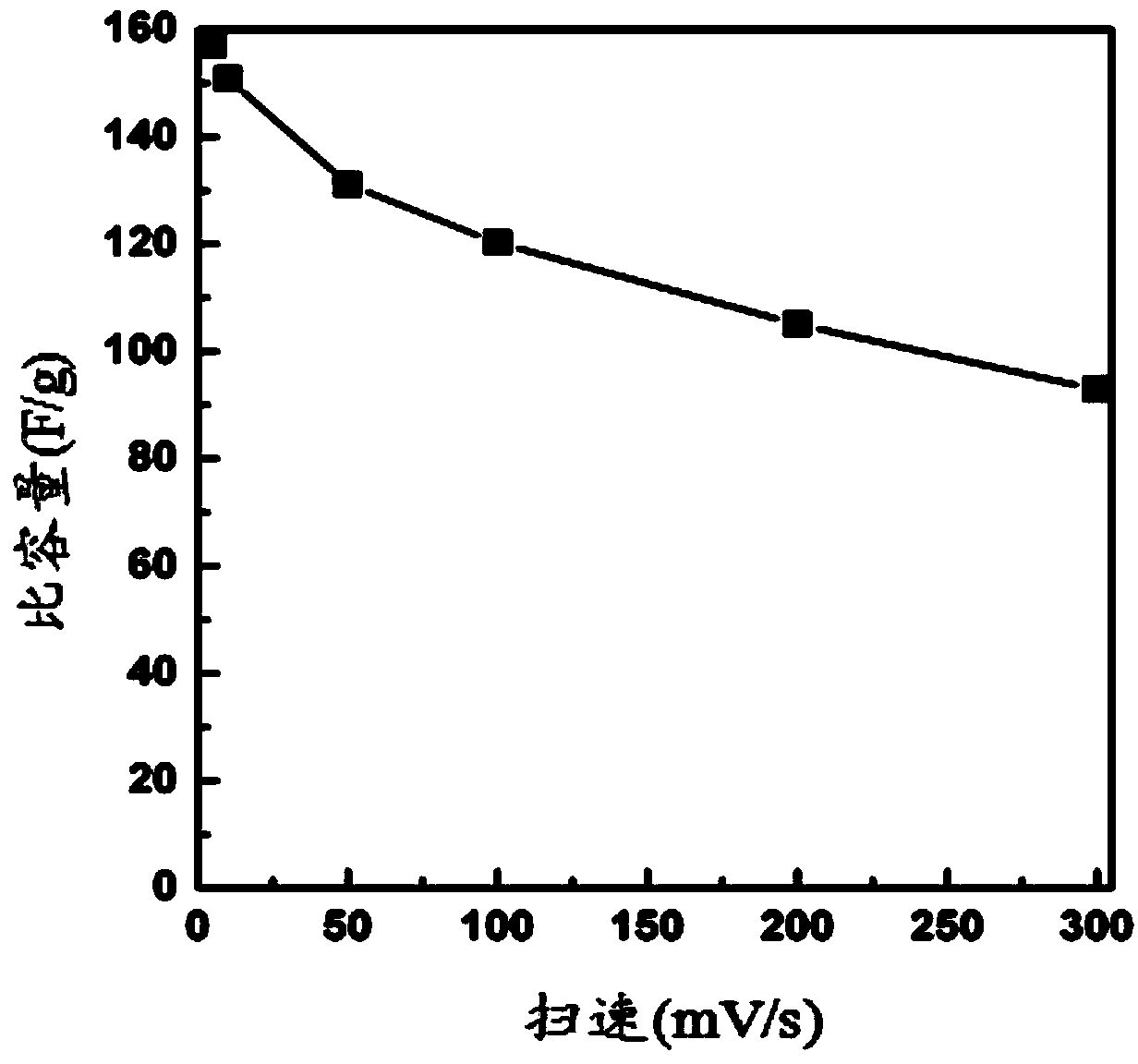

A technology of porous graphene and graphite, which is applied in the field of carbon materials, can solve the problems of low energy density, decreased specific capacity, and hindered ion diffusion of activated carbon, etc., and achieve the effect of high rate charge and discharge performance and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of porous graphene, comprising the following steps: under the action of an oxidizing agent, graphite substances and sulfur are heated and reacted in a solvent to obtain porous graphene, and the graphite substances are graphene oxide, One or more of graphene and nano-graphite microflakes.

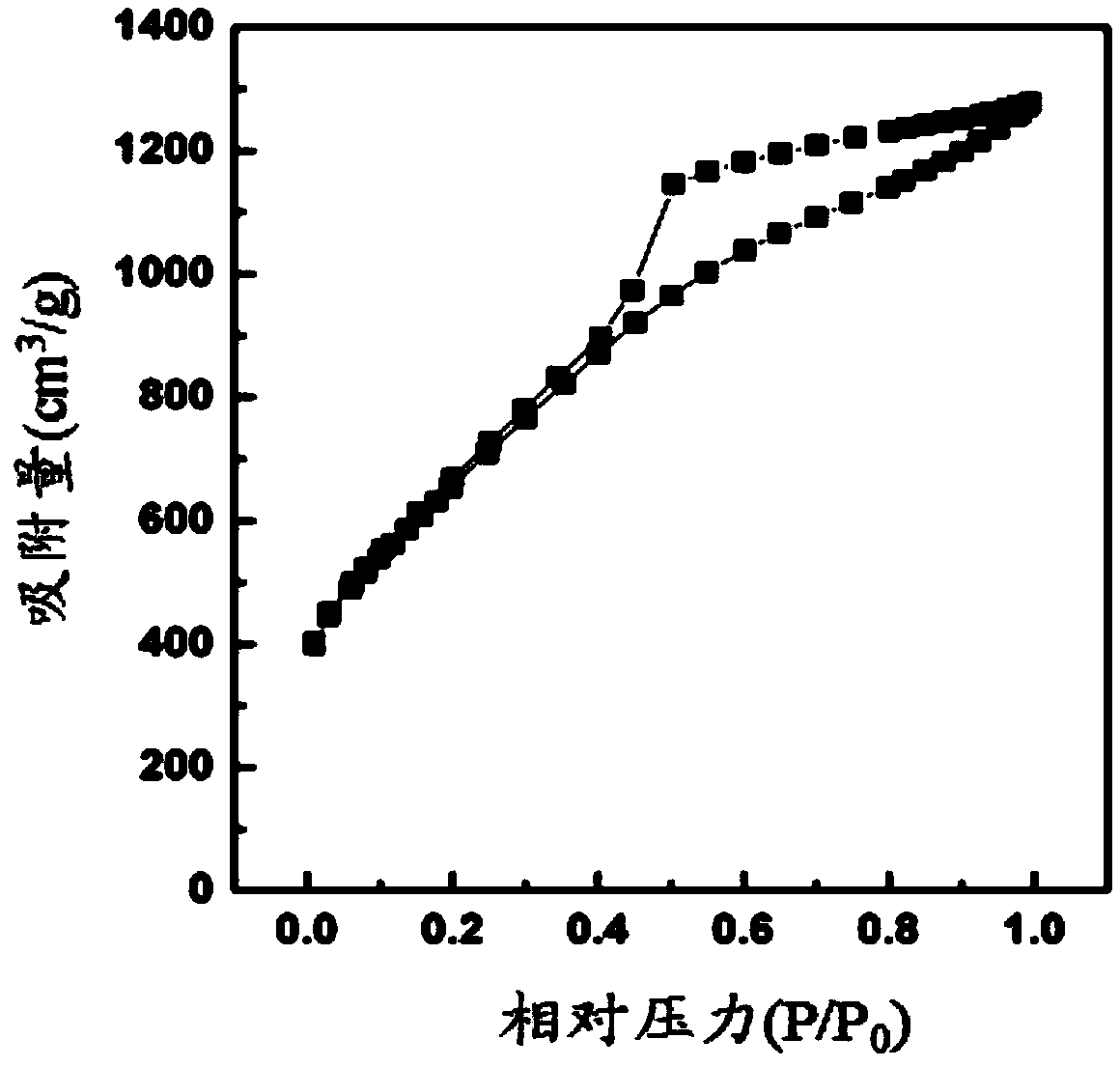

[0027] The porous graphene prepared by the method of the invention has a mesopore structure and a relatively high specific surface area.

[0028] All the raw materials of the present invention have no special limitation on their sources, they can be purchased in the market.

[0029] The present invention is not particularly limited to the source of described graphene oxide, preferably adopts improved Hummers method preparation:

[0030] 1.5g of graphite, 1.5g of potassium nitrate and 90mL of concentrated sulfuric acid were mixed and reacted with 9g of potassium permanganate. After the reaction, 100mL of deionized water and 2mL of hydrogen p...

Embodiment 1

[0053] First, 1.5g of graphite, 1.5g of potassium nitrate and 90mL of concentrated sulfuric acid were mixed and reacted with 9g of potassium permanganate. After the reaction, 100mL of deionized water and 2mL of hydrogen peroxide were added to obtain 2g of graphene oxide.

[0054] Then 0.6g of sulfur was dissolved in 10ml of carbon disulfide to obtain a carbon disulfide solution of sulfur, 0.3g of graphene oxide was impregnated in the solution of carbon disulfide of sulfur, and the impregnated graphene oxide was dried to obtain the first mixture.

[0055] Dissolve 10 g of potassium nitrate in 50 ml of deionized water to obtain an aqueous potassium nitrate solution, then mix the first mixture with the aqueous potassium nitrate solution evenly, and dry to obtain a second mixture.

[0056] Finally, the above-mentioned second mixture was subjected to microwave treatment with a power of 1 kilowatt and a treatment time of 3 minutes. After the treatment, the mixture was taken out and w...

Embodiment 2

[0063] Dissolve 6g of sulfur in 50ml of carbon disulfide to obtain a carbon disulfide solution of sulfur, impregnate 3g of nanometer graphite flakes in the above carbon disulfide solution of sulfur, and then dry the impregnated graphite nanometer flakes to obtain the first mixture.

[0064] Dissolve 10 g of potassium nitrate in 50 ml of deionized water to obtain an aqueous potassium nitrate solution, then mix the first mixture with the aqueous potassium nitrate solution evenly, and dry to obtain a second mixture.

[0065] Finally, the above-mentioned second mixture was heated in a muffle furnace for 30 seconds at a temperature of 500°C. After the treatment, it was taken out and washed with deionized water to remove ions, and dried to obtain 2g of porous graphene.

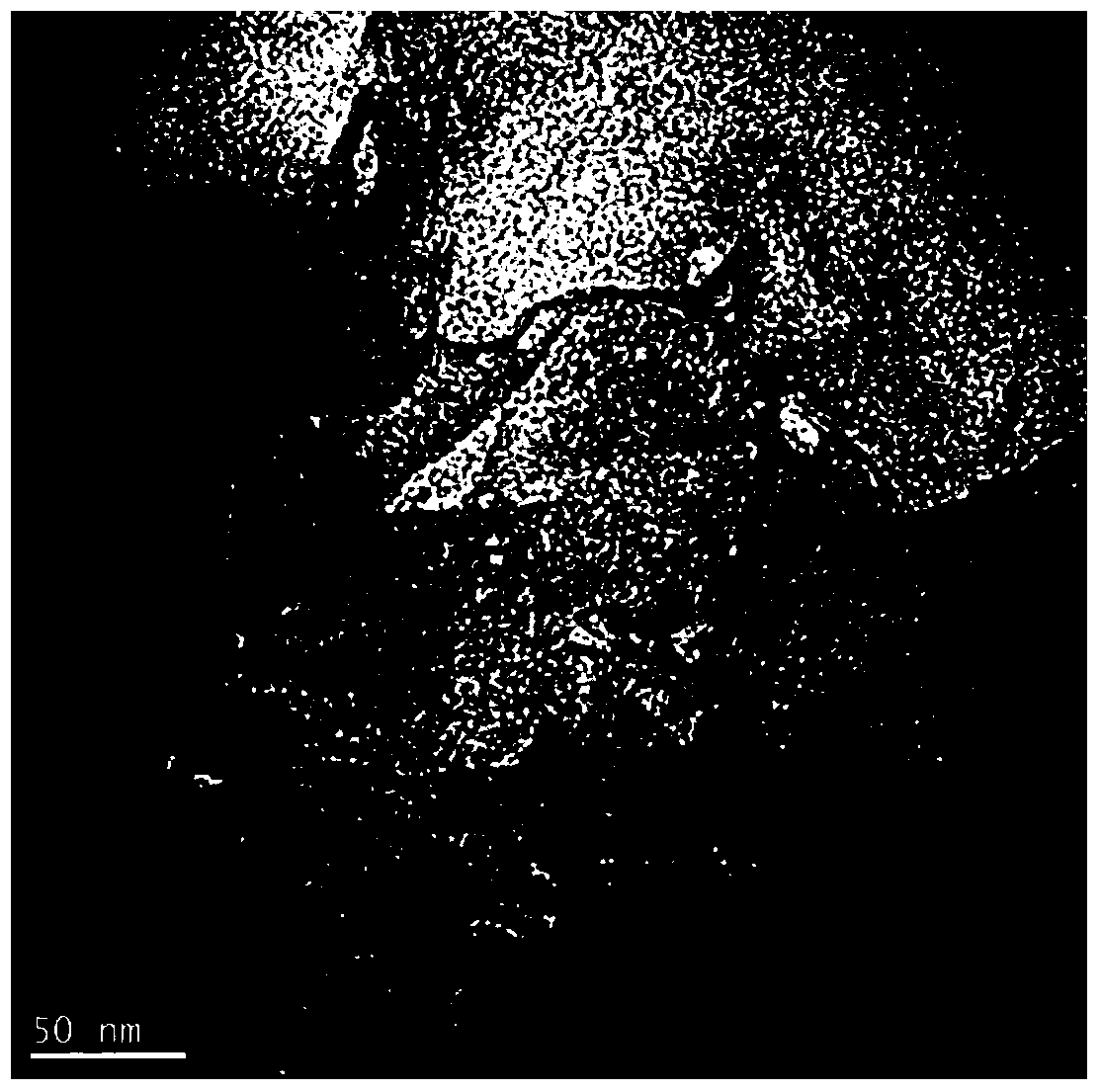

[0066] Detected by a transmission electron microscope, the pore diameter of the porous graphene obtained by the present invention is about 5-45 nm. The obtained porous graphene is tested by nitrogen adsorption, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com