Method for preparing ferrum electrode material of ferro-nickel rechargeable secondary battery

A secondary battery and iron electrode technology, applied in the field of preparation of rechargeable graphene-modified iron electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

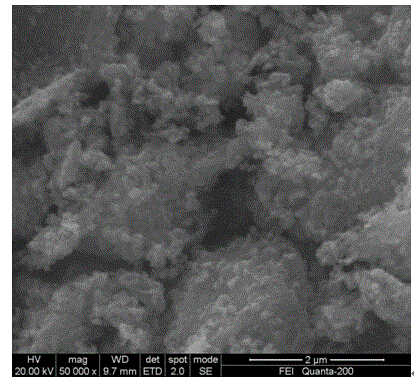

Image

Examples

Embodiment 1

[0024] Weigh 9.6g FeCl 3 ·6H 2 O and 23.9g of sodium oleate were dissolved in a mixed solvent consisting of 20ml of absolute ethanol, 40ml of deionized water and 50ml of n-hexane, and kept in a constant temperature water bath at 85°C for 2h. Let it stand, and take the upper layer of reddish-brown iron-based oleate with a separatory funnel. Another 20 mg of heat-expandable graphene sheet was taken, added into a mixed solvent composed of 15 ml of oleylamine and 20 ml of toluene, and ultrasonicated for 12 hours. The mixture was centrifuged at 5000rpm to obtain oleylamine-modified graphene nanosheets. Dissolve 2g of iron-based oleate and 20mg of oleylamine-modified graphene nanosheets in 50ml of xylene, heat in a water bath at 80°C for 15min, then transfer to a reaction kettle, and react at 150°C for 10h. The product was washed with alcohol and water, and dried to obtain the iron electrode precursor composite of graphene sheets, which was heat-treated in a tube furnace at a rat...

Embodiment 2

[0026] Weigh 8.7g FeCl 3 ·6H 2 O and 55.6g of sodium oleate were dissolved in a mixed solvent consisting of 30ml of absolute ethanol, 60ml of deionized water and 100ml of n-hexane, and kept in a constant temperature water bath at 85°C for 2h. Let it stand, and take the upper layer of reddish-brown iron-based oleate with a separatory funnel. Another 10 mg of heat-expandable graphene sheet was taken, added into a mixed solvent composed of 10 ml of oleylamine and 20 ml of toluene, and ultrasonicated for 12 hours. The mixture was centrifuged at 5000rpm to obtain oleylamine-modified graphene nanosheets. Dissolve 2g of iron-based oleate and 10mg of oleylamine-modified graphene nanosheets in 50ml of xylene, heat in a water bath at 80°C for 15min, then transfer to a reaction kettle, and react at 150°C for 10h. The product is washed with alcohol and water, and dried to obtain an iron-electrode composite of graphene sheets without heat treatment.

Embodiment 3

[0028] Weigh 9.6g FeCl 3 ·6H 2 O and 24.8g of potassium oleate were dissolved in a mixed solvent composed of 20ml of absolute ethanol, 40ml of deionized water and 50ml of n-hexane, and kept in a constant temperature water bath at 75°C for 4h. Let it stand, and take the upper layer of reddish-brown iron-based oleate with a separatory funnel. Another 20 mg of heat-expandable graphene sheet was taken, added into a mixed solvent composed of 15 ml of oleylamine and 20 ml of toluene, and ultrasonicated for 12 hours. The mixture was centrifuged at 5000rpm to obtain oleylamine-modified graphene nanosheets. Weigh 1g of iron-based oleate, mix with 20mg of heat-expandable graphene sheets and 100ml of xylene, heat in a water bath at 80°C for 15min, then transfer to a reaction kettle, and react at 150°C for 12h. The product was washed with alcohol and water, and dried to obtain the iron electrode precursor composite of graphene sheets, which was heat-treated in a tube furnace at a rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com