Novel mixed super capacitor

A supercapacitor, a new type of technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve problems such as expensive, large-scale commercial application restrictions, and narrow charge and discharge potential range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

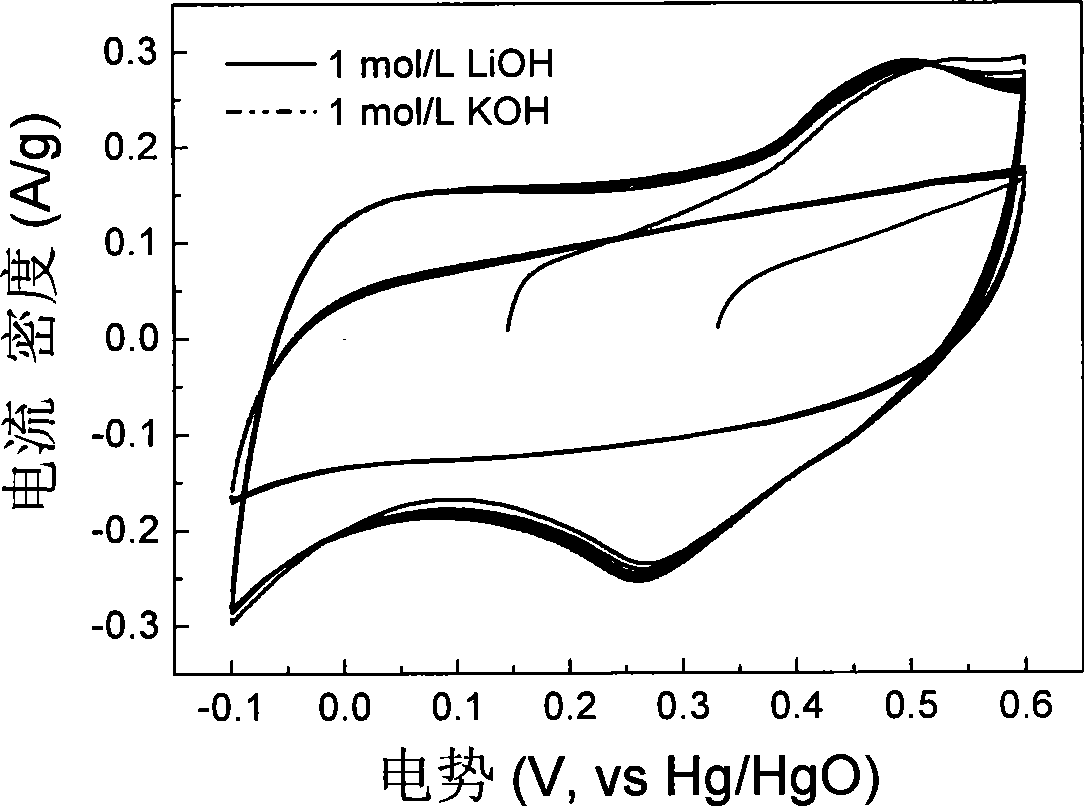

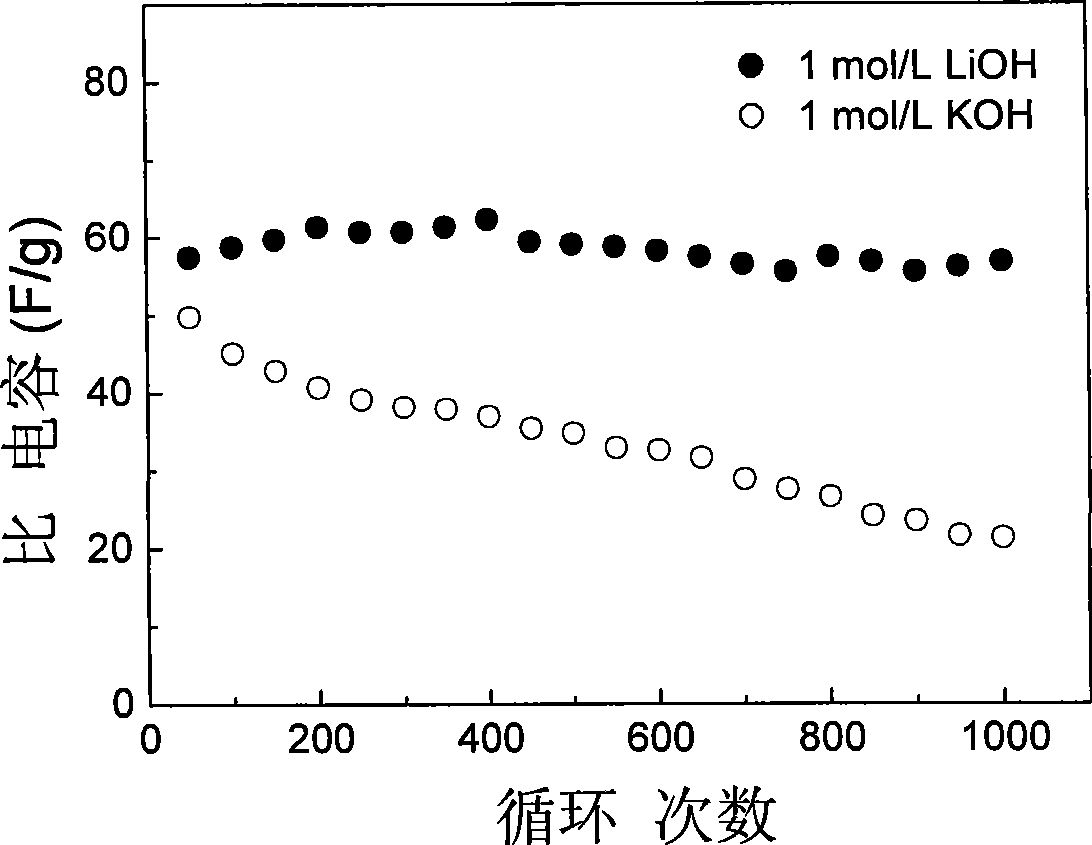

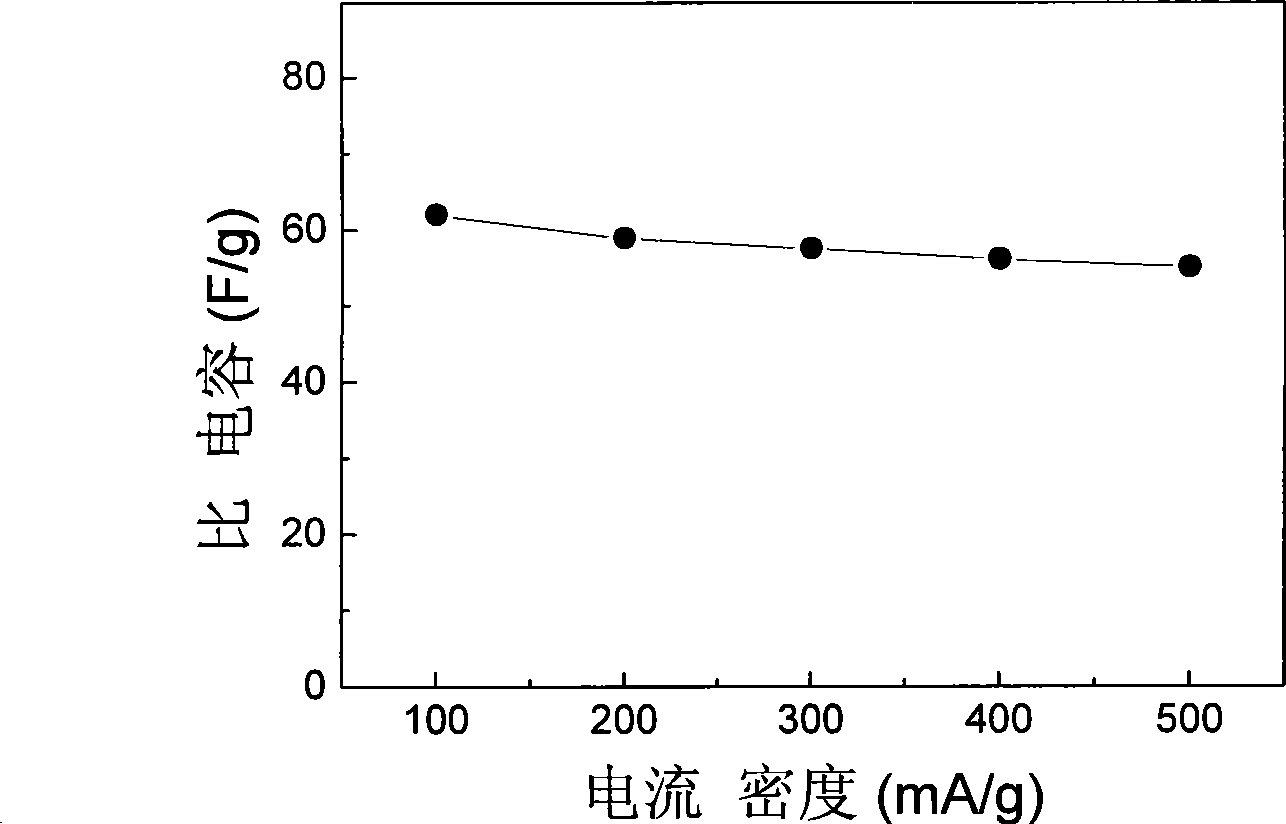

[0024] Embodiment 1: The hybrid supercapacitor of the present invention is made up of a positive electrode sheet, a negative electrode sheet, a diaphragm between the two, and an alkaline electrolyte with ion conductivity, and is characterized in that: the positive electrode active material of the capacitor is Nano MnO 2 The electrode material, the negative electrode active material is porous activated carbon, the diaphragm is a polypropylene film, and the electrolyte is LiOH aqueous solution with a concentration of 1 mol / liter to 3 mol / liter.

[0025] The production of the positive electrode sheet: manganese acetate (MnAc 2 4H 2 O) and citric acid (C 6 h 8 o 7 ·H 2 O) as a raw material, ground in a mortar, a low-heat solid-state reaction occurs, and a precursor is obtained. The precursor is calcined in an air atmosphere at 300°C for 10 hours, and then subjected to 2mol / L H 2 SO 4 The solution was acidified for 2 hours, washed and dried to obtain nano-MnO 2 Material. N...

Embodiment 2

[0026] Embodiment two: this embodiment is basically the same as embodiment 1, the difference is: with the manganese chloride (MnCl 2 4H 2 O) and ammonium bicarbonate (NH 4 HCO 3 ) as a raw material, ground in a mortar, a low-heat solid-state reaction occurs, and a precursor (MnCO 3 with NH 4 Cl mixture), the precursor was calcined at 350°C in an air atmosphere for 10 hours, and then subjected to 2mol / LH 2 SO 4 The solution was acidified for 2 hours, washed and dried to obtain nano-MnO 2 Material. The nanometer MnO obtained by this method is used in the positive electrode 2 Material production, negative electrode, electrolyte and separator are all the same as in Example 1, and the manufacturing process of the electrode is also the same as in Example 1, forming nano-MnO 2 / Activated carbon supercapacitor. The charge-discharge cycle life of the capacitor at a voltage range of 0.5-1.5V and a current density of 500mA / g is as follows: Figure 4 shown. After 5000 cycles, ...

Embodiment 3

[0027] Embodiment three: the present embodiment is basically the same as embodiment 1, the difference is: with the manganese chloride (MnCl 2 4H 2 O) and ammonium oxalate ((NH 4 ) 2 C 2 o 4 ·H 2 O) as a raw material, ground in a mortar, a low-heat solid-phase reaction occurs. The solid-phase reaction product was dissolved in water to remove soluble matter, and the manganese oxalate precursor was obtained after drying. The precursor was calcined in air at 400°C for 10 hours, and then subjected to 2mol / L H 2 SO 4 The solution was acidified for 2 hours, washed and dried to obtain nano-MnO 2 Material. The nanometer MnO obtained by this method is used in the positive electrode 2 Material production, negative electrode, electrolyte and separator are all the same as in Example 1, and the manufacturing process of the electrode is also the same as in Example 1, forming nano-MnO 2 / Activated carbon supercapacitor. The energy-power relationship (Ragone diagram) of the capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com