Patents

Literature

37results about How to "Improve cathode performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

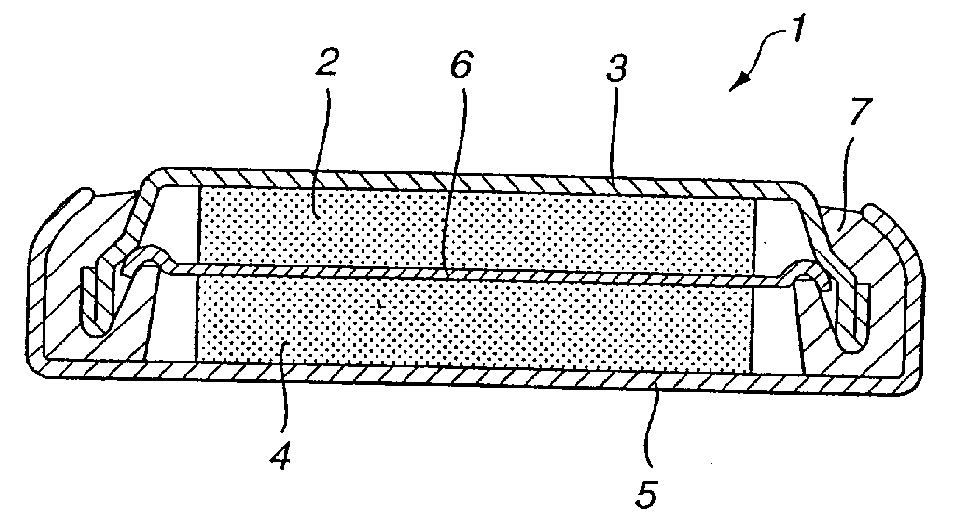

Low temperature electrochemical cell

InactiveUS20070218364A1Improve electronic performanceImprove performanceOrganic electrolyte cellsNon-aqueous electrolyte accumulator electrodesCelsius DegreeRoom temperature

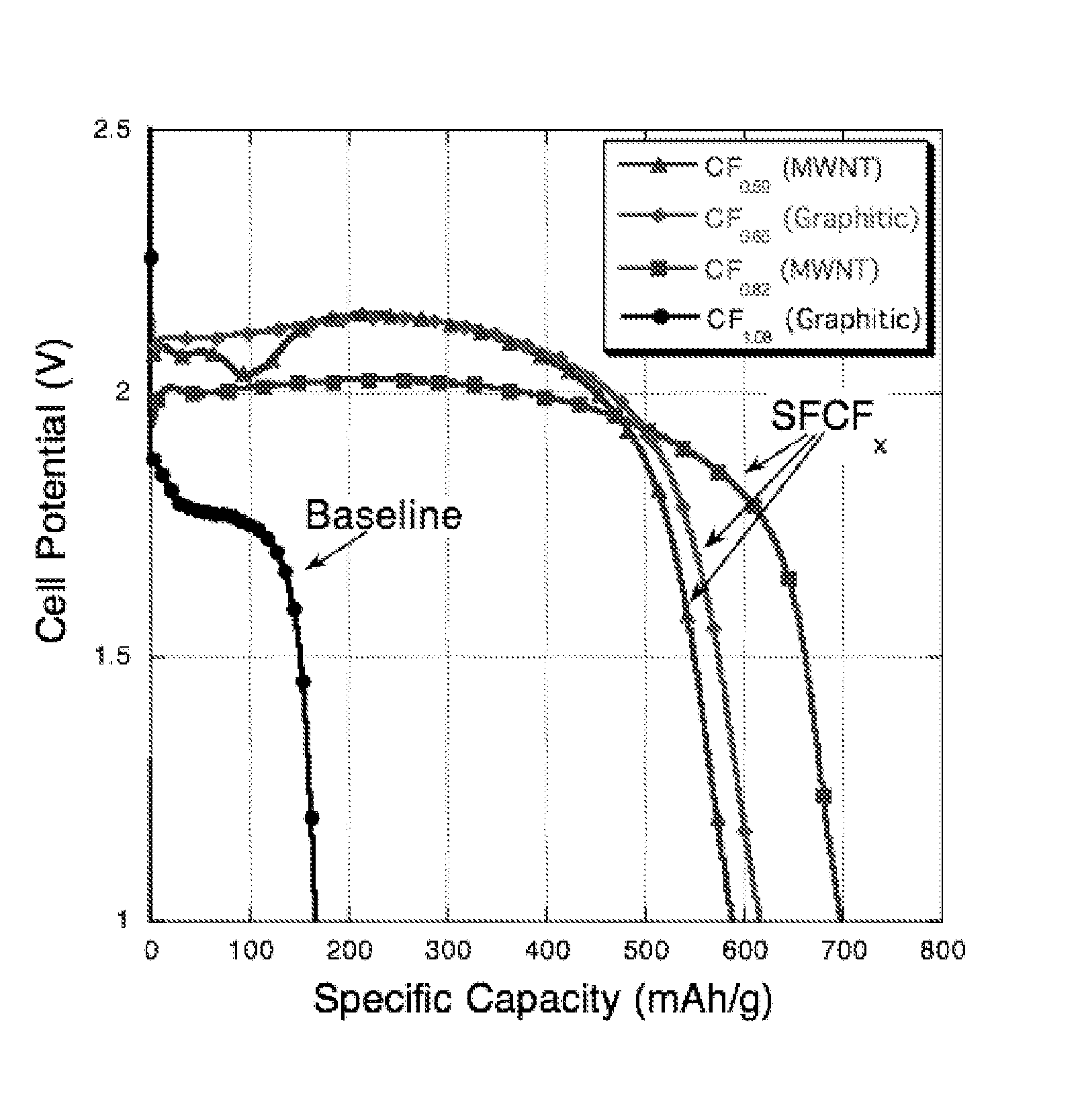

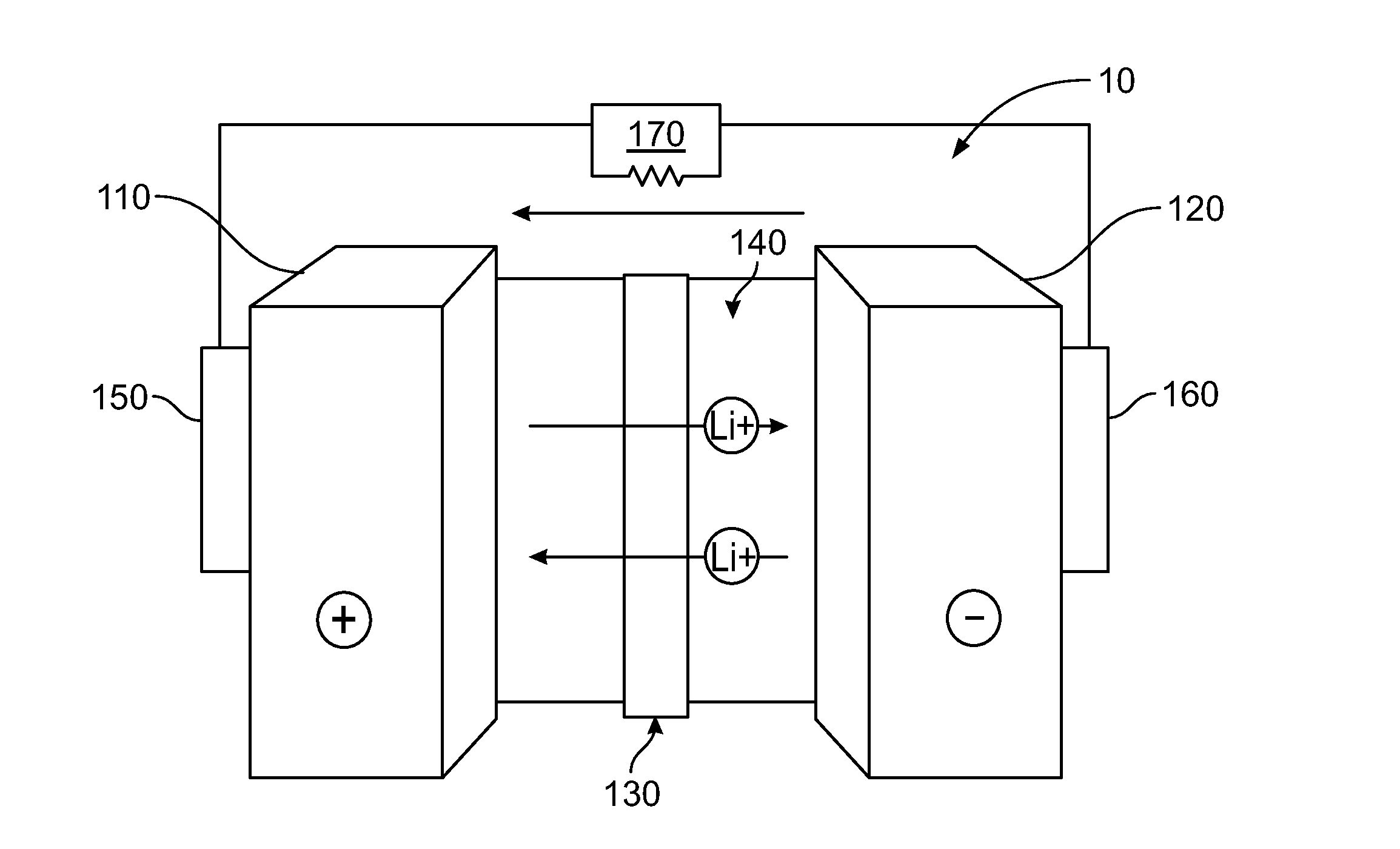

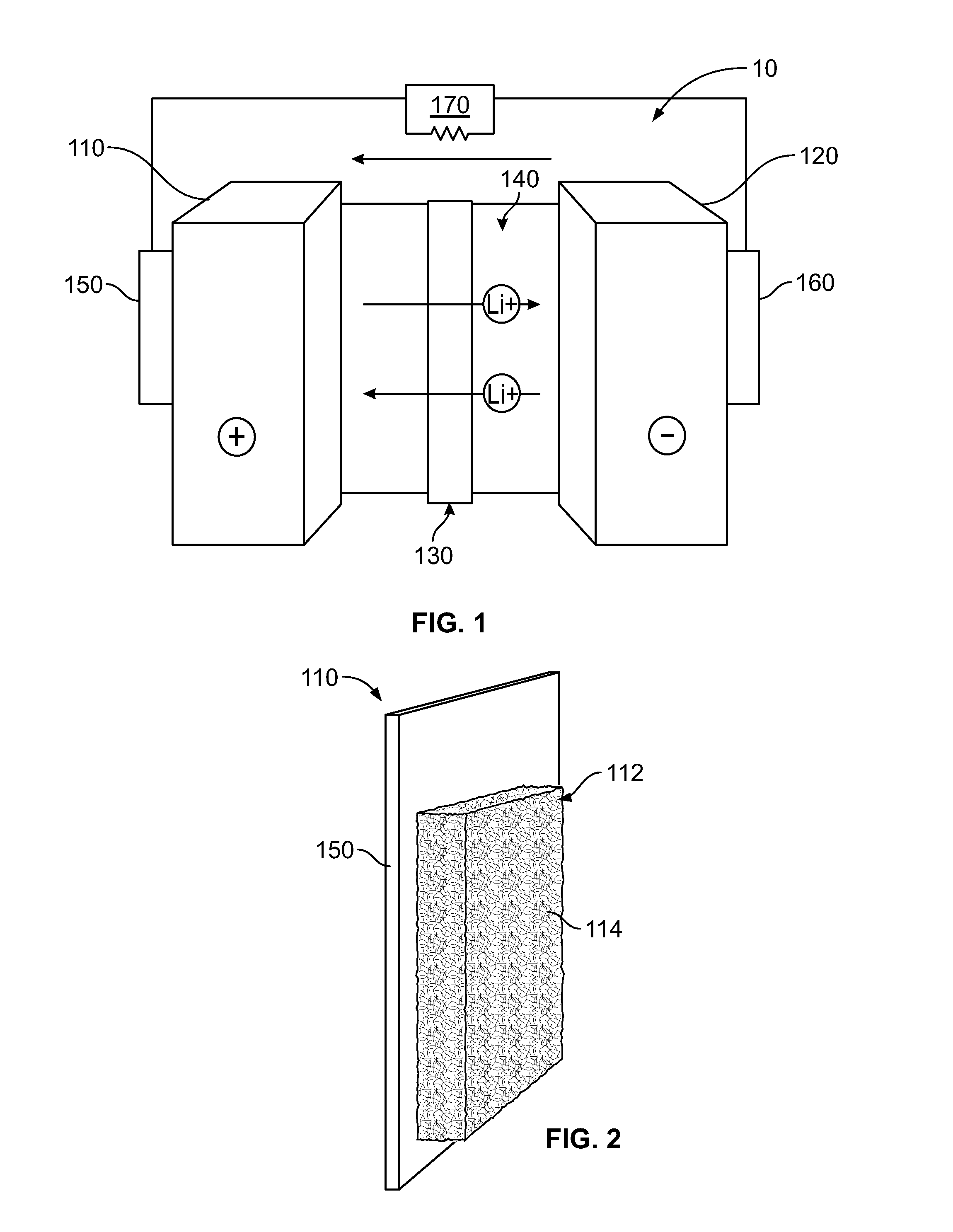

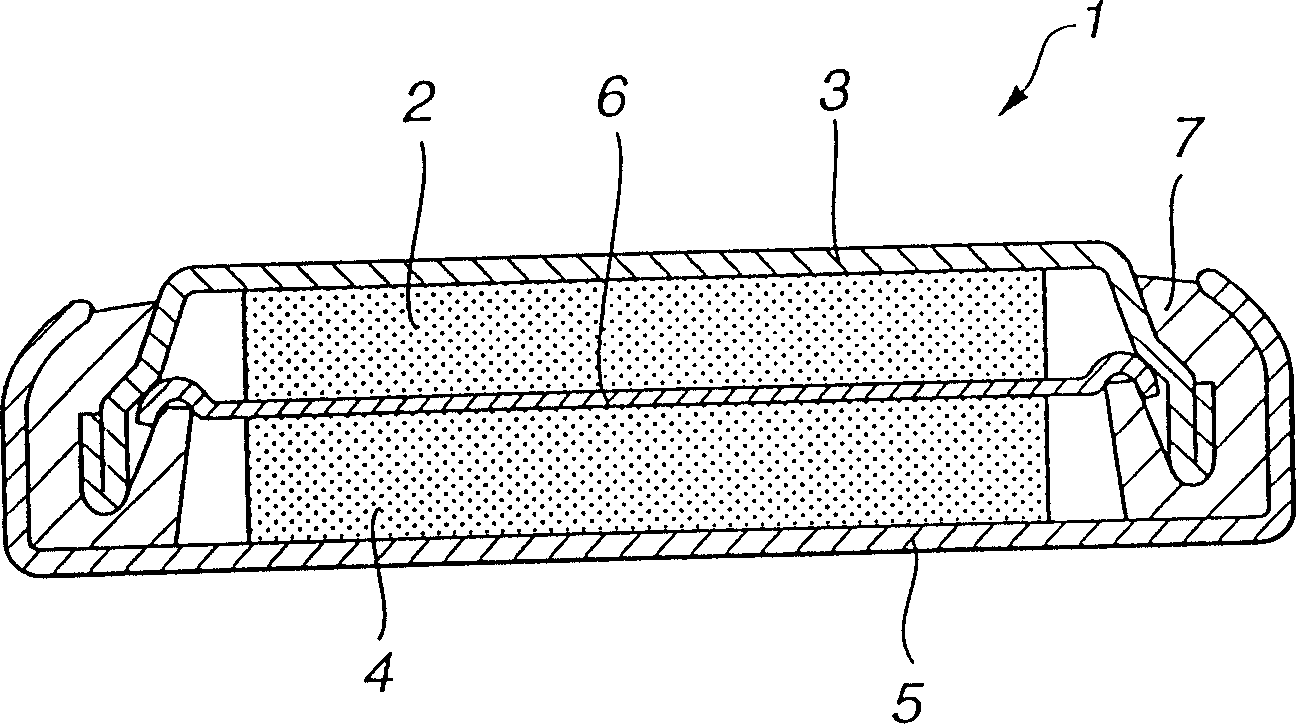

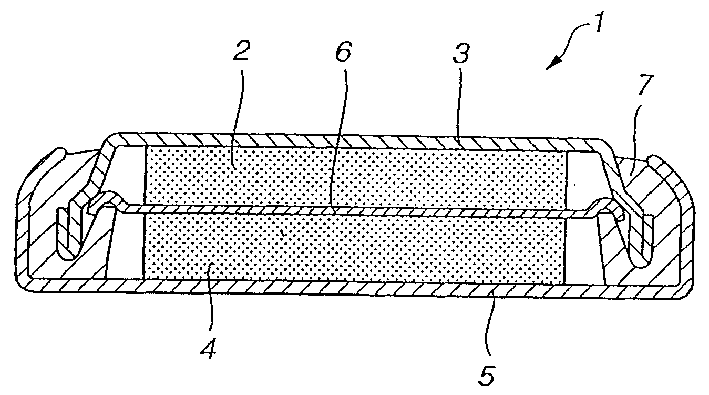

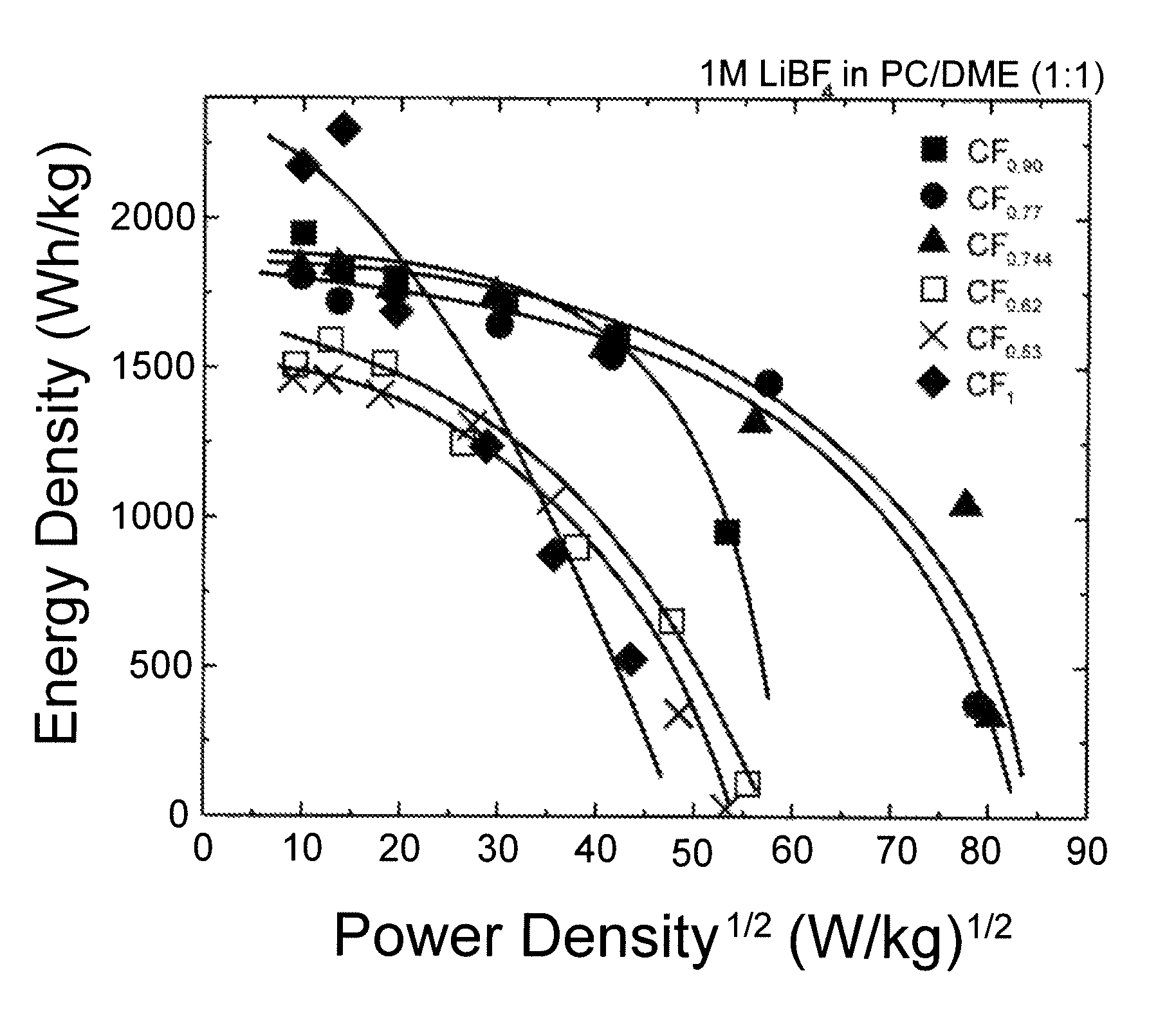

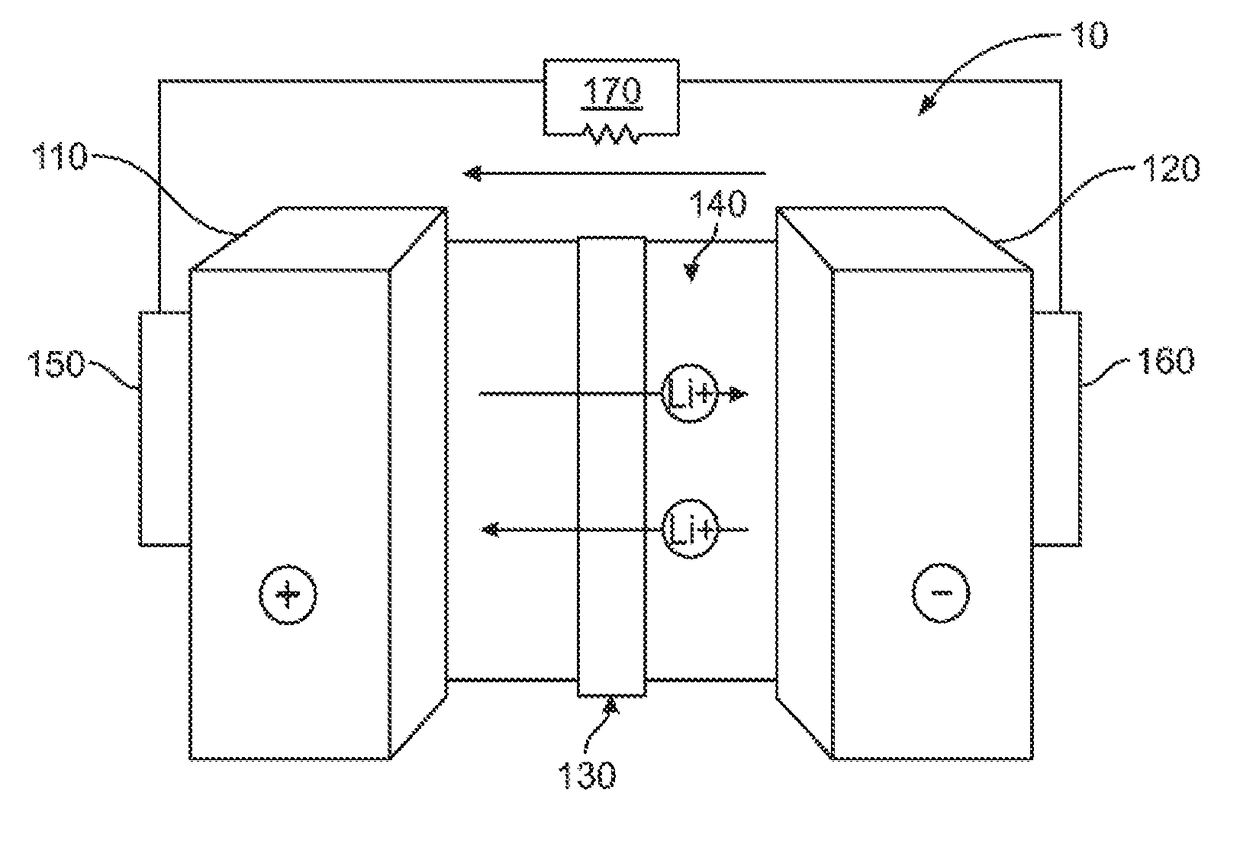

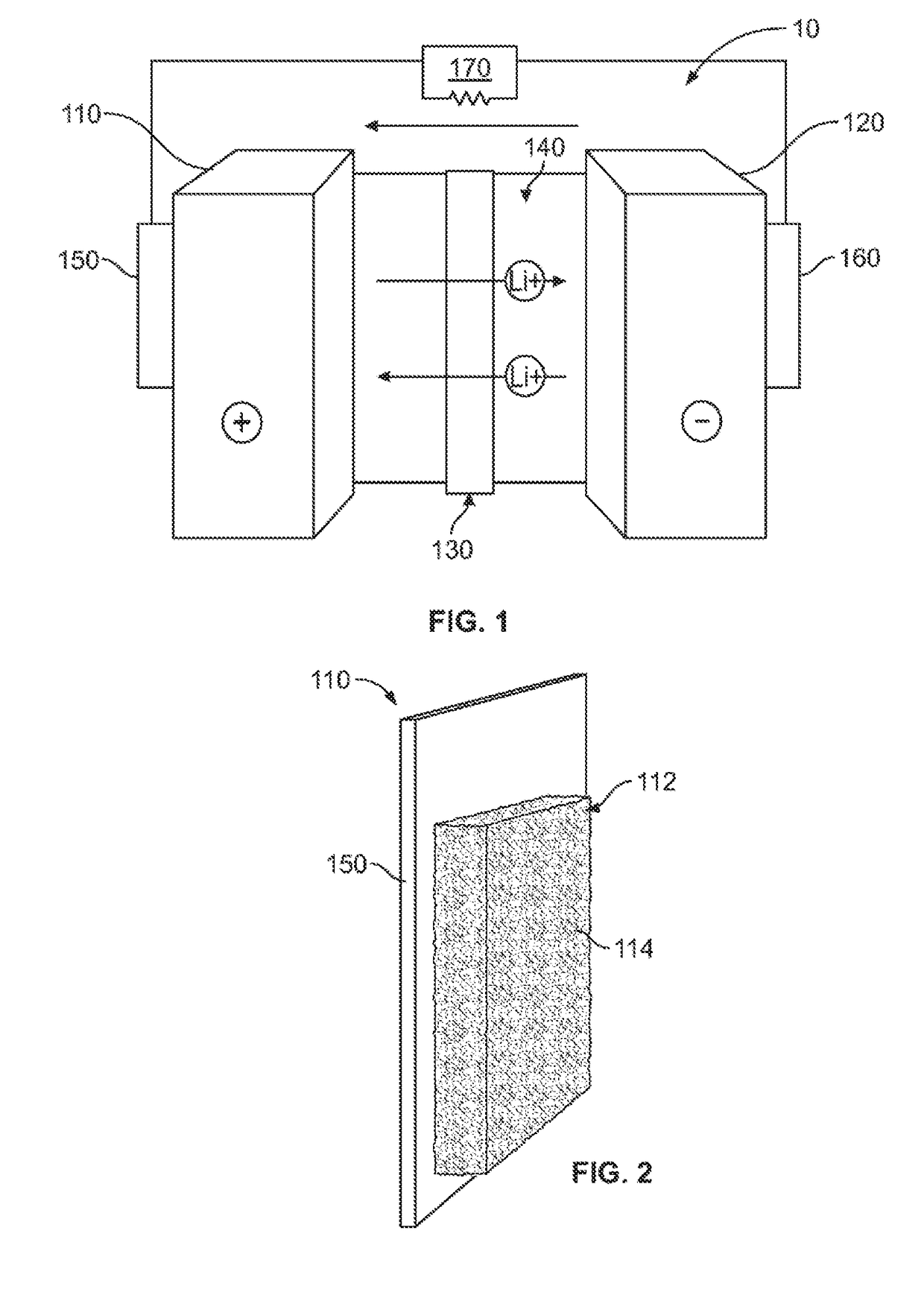

The present invention provides electrochemical cells providing good electronic performance at low temperatures. Electrochemical cells of the present invention include lithium batteries capable of providing useful specific capacities under significant discharge rates for temperatures as low as −60 degrees Celsius. The present invention also provides methods for making electrochemical cells including a room temperature predischarge step preceding low temperature operation that enhances the performance of batteries having subfluorinated carbonaceous positive electrode active materials at low temperatures.

Owner:CALIFORNIA INST OF TECH +2

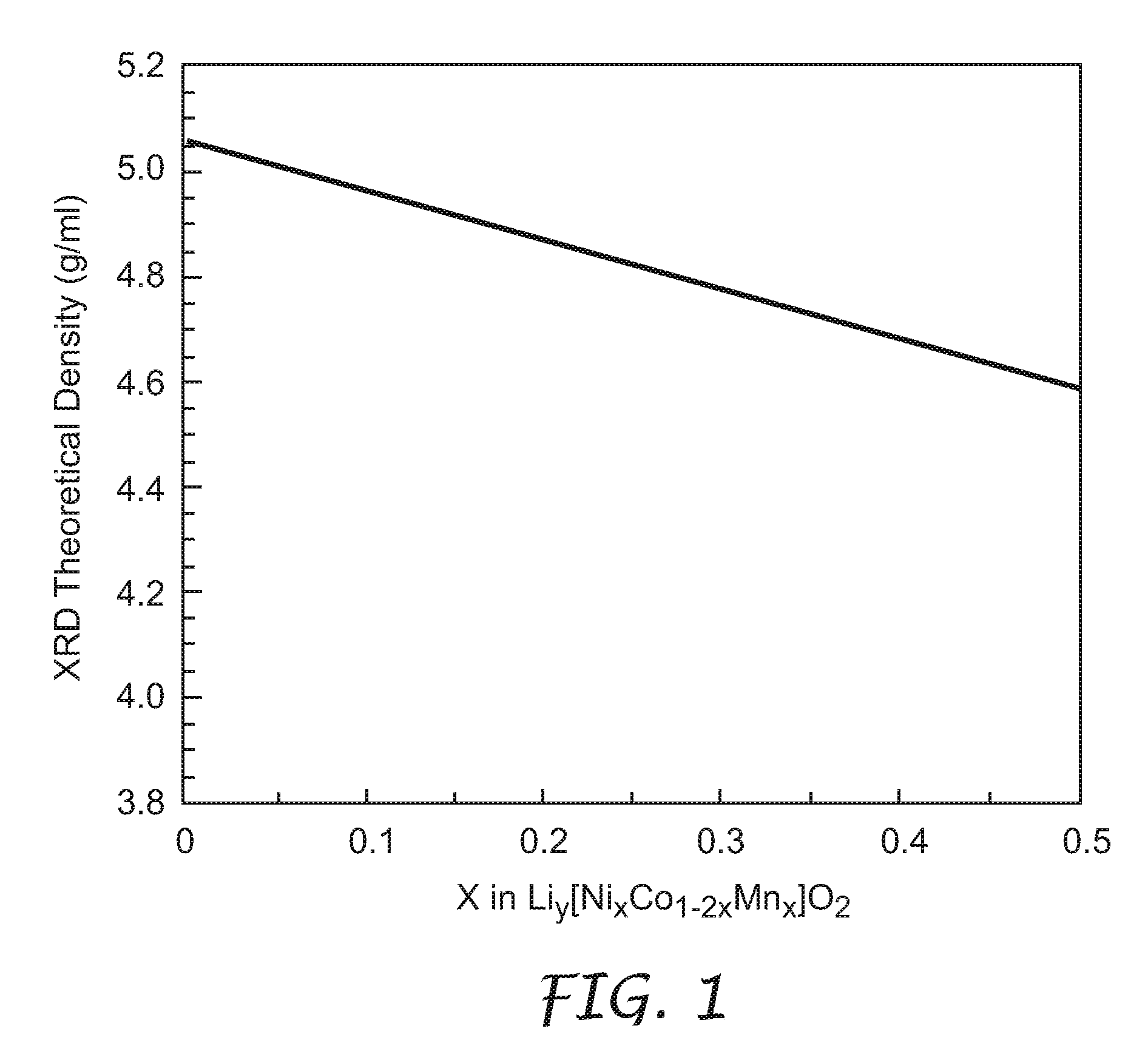

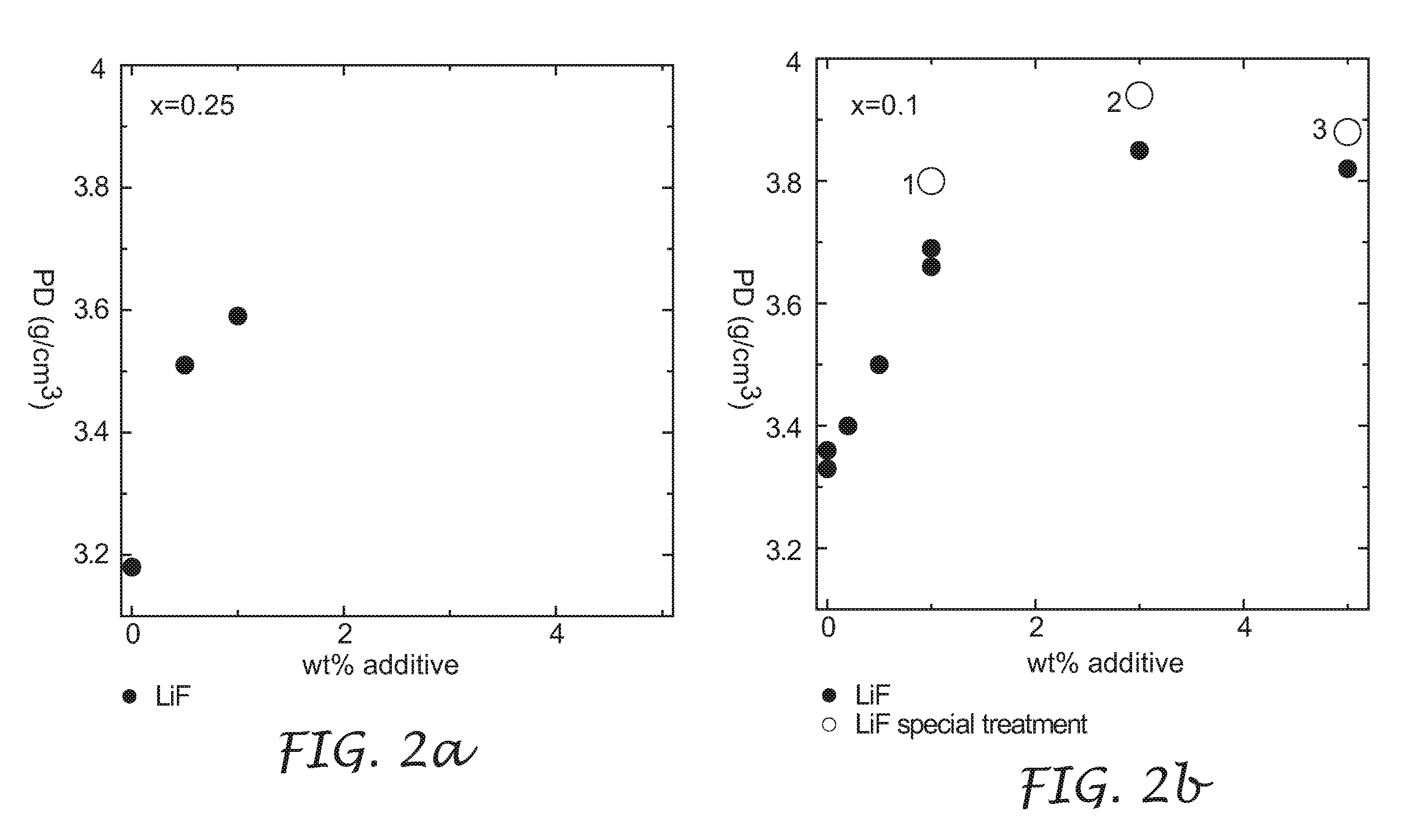

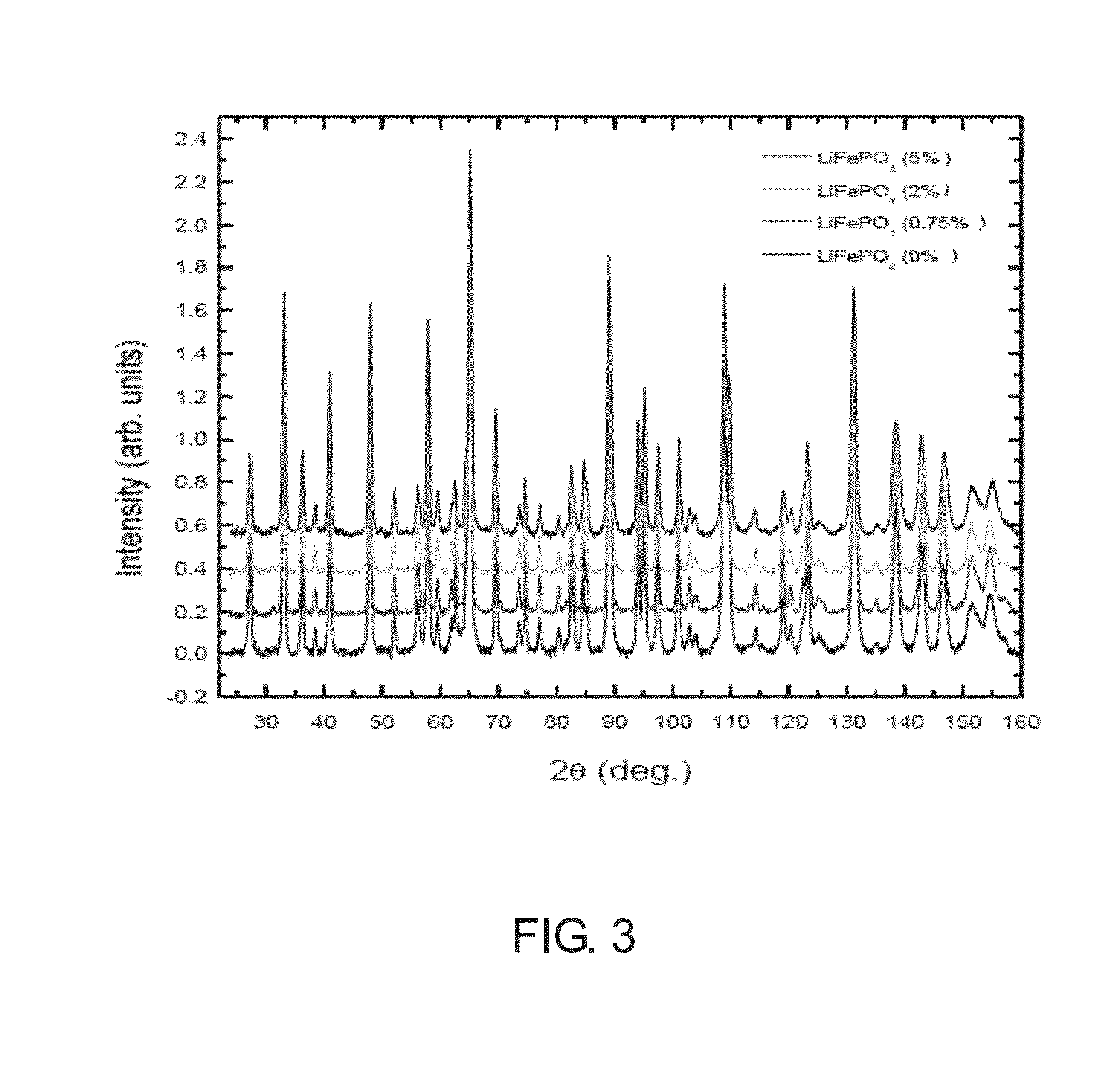

Method of producing lithium ion cathode materials

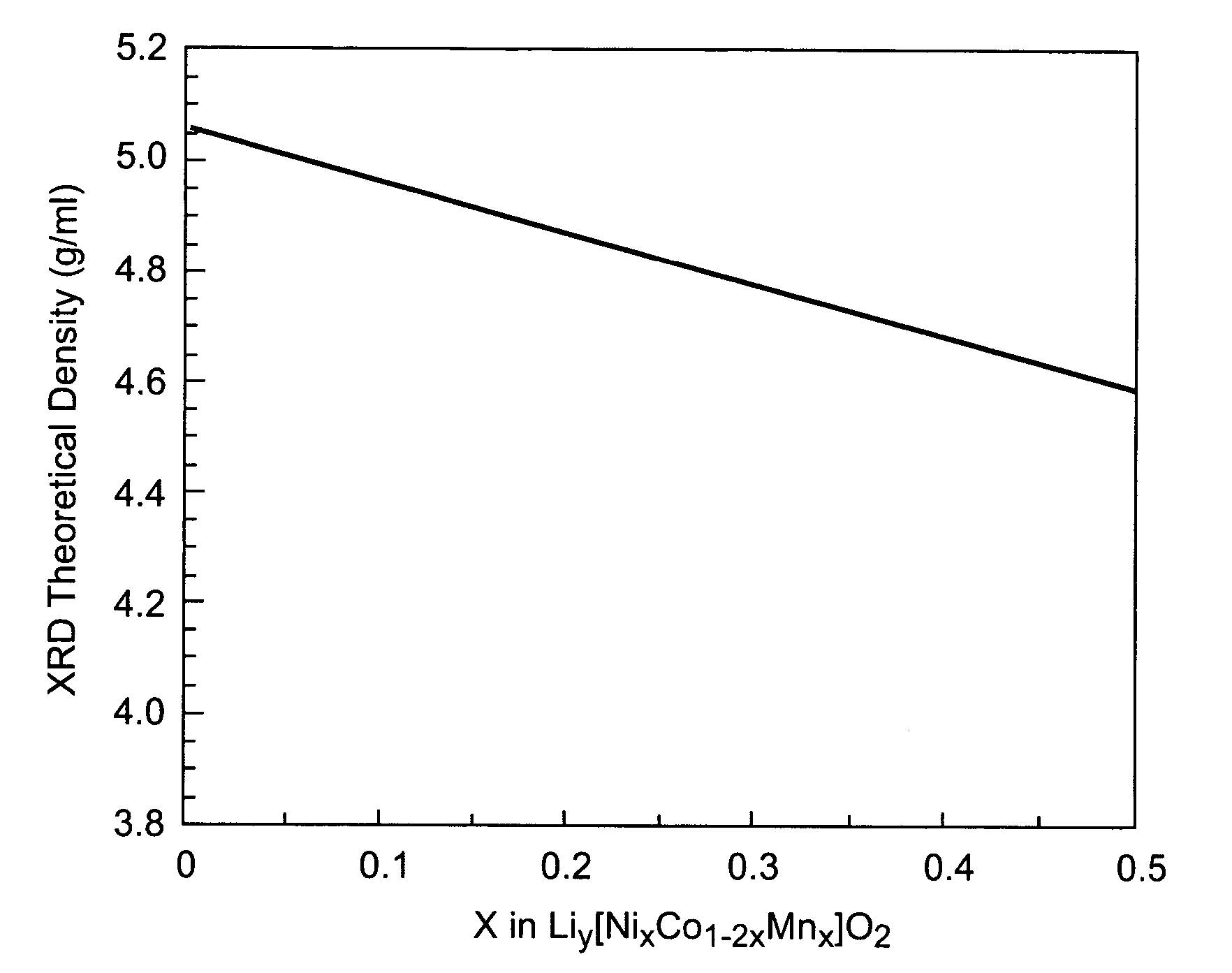

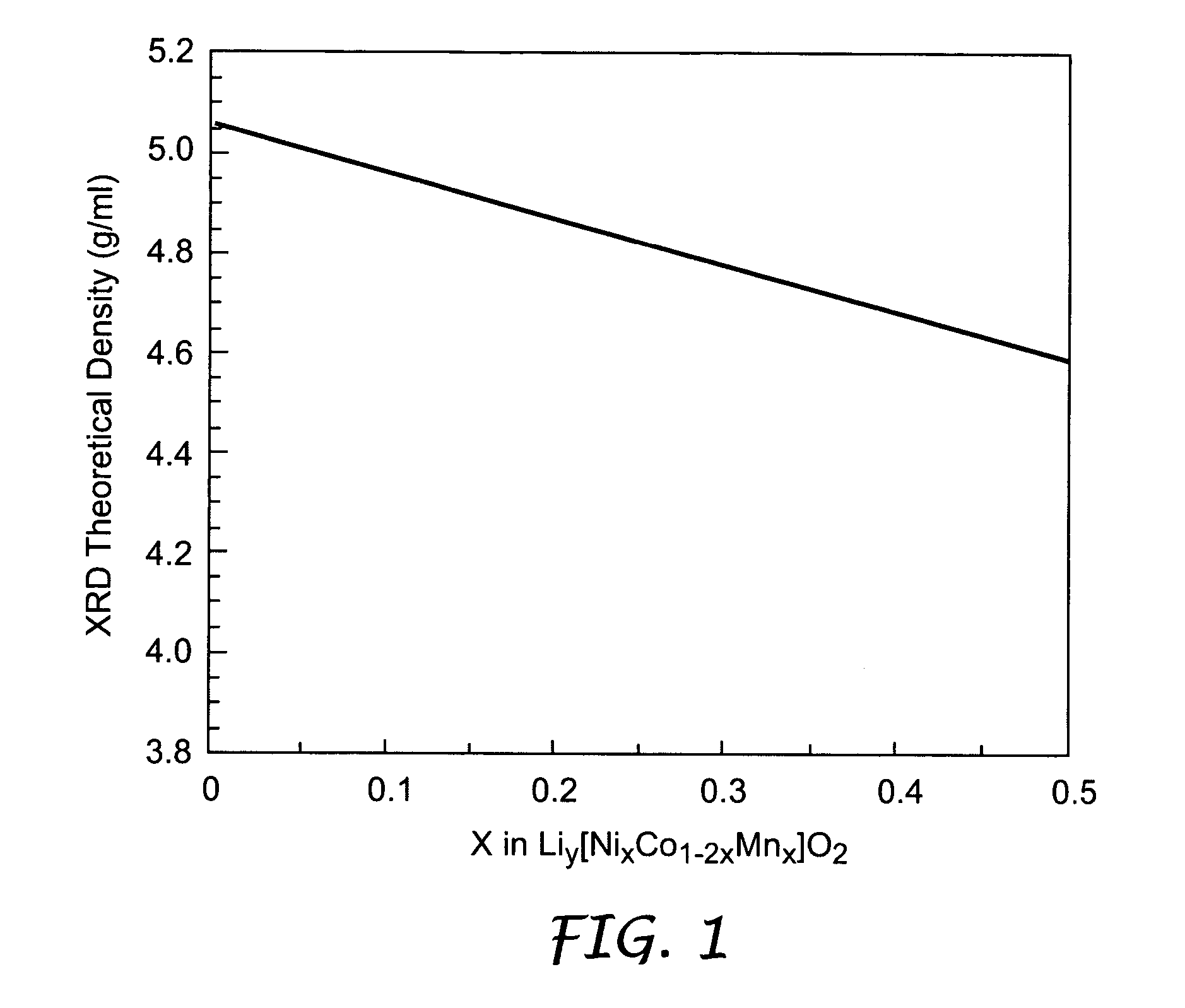

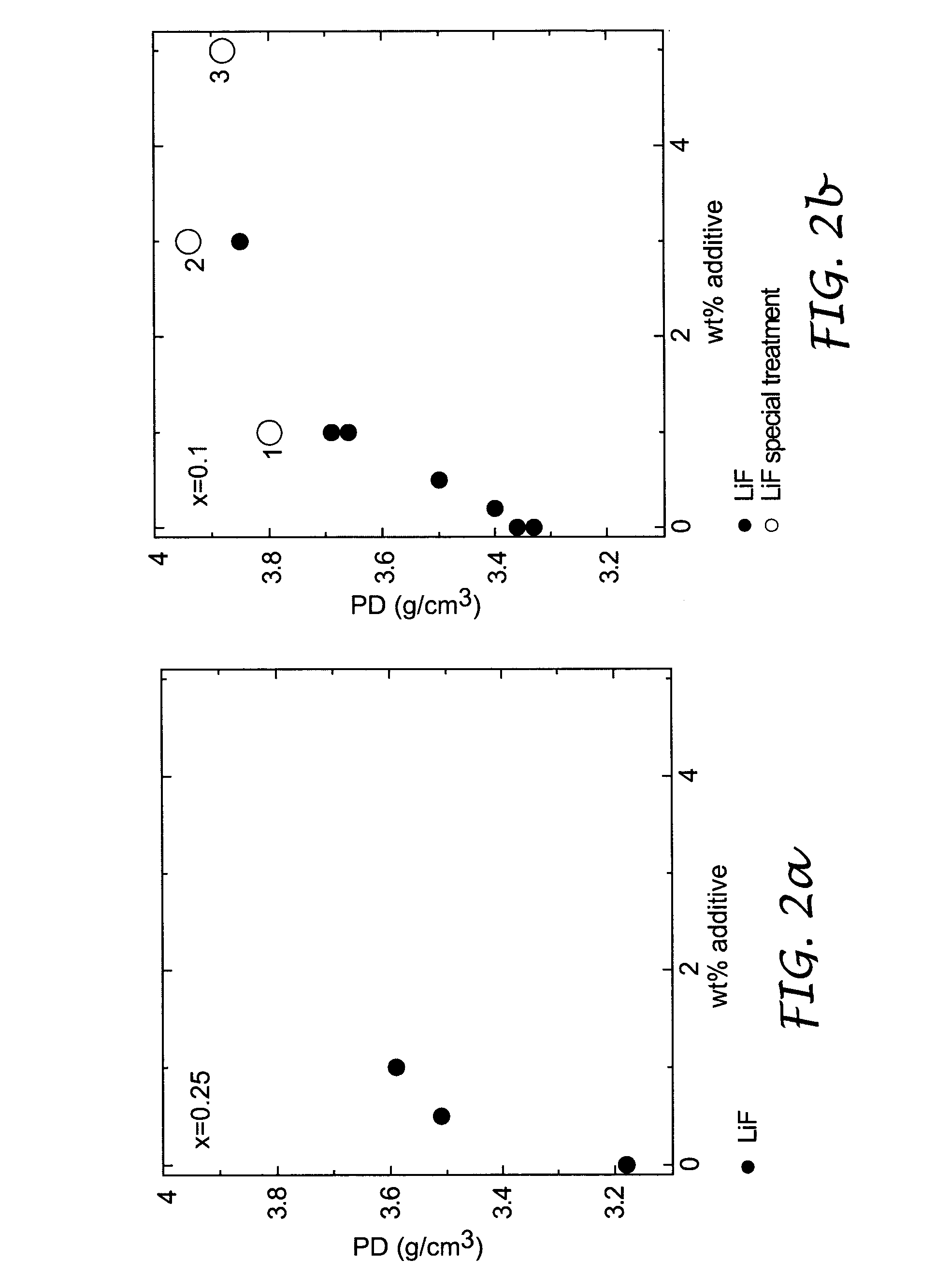

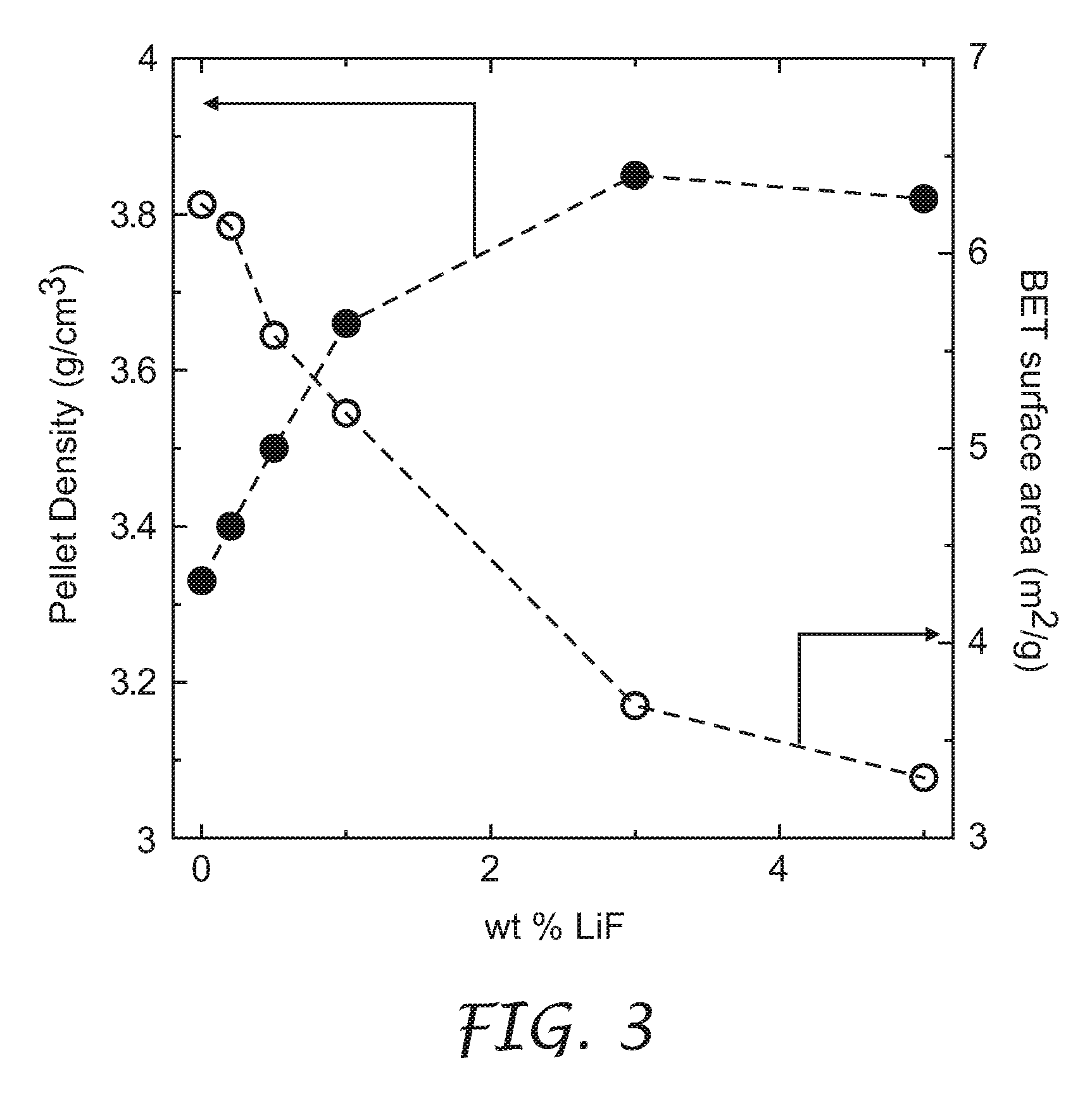

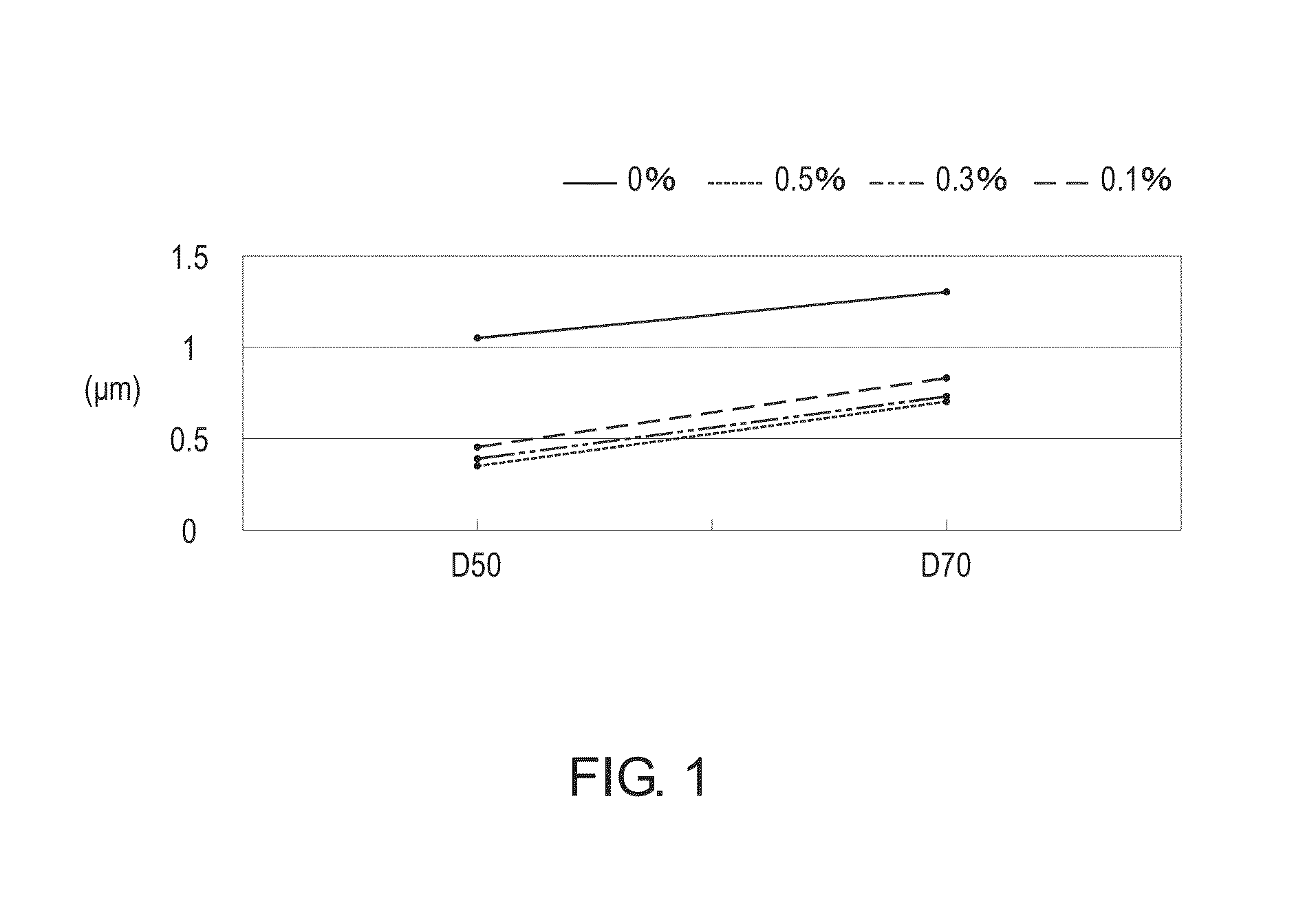

InactiveUS7556655B2High densityReduce irreversible capacityElectrode manufacturing processesPrimary cellsFluorideBoron

A method of producing Liy[NixCo1−2xMnx]O2 wherein 0.025≦x≦0.5 and 0.9≦y≦1.3. The method includes mixing [NixCo1−2xMnx]OH2 with LiOH or Li2CO3 and one or both of alkali metal fluorides and boron compounds, preferably one or both of LiF and B2O3. The mixture is heated sufficiently to obtain a composition of Liy[NixCo1−2xMnx]O2 sufficiently dense for use in a lithium-ion battery cathode. Compositions so densified exhibit a minimum reversible volumetric energy characterized by the formula [1833-333x] measured in Wh / L.

Owner:3M INNOVATIVE PROPERTIES CO

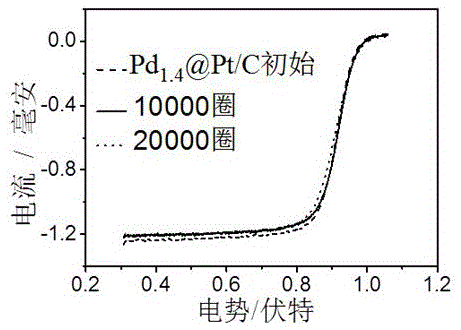

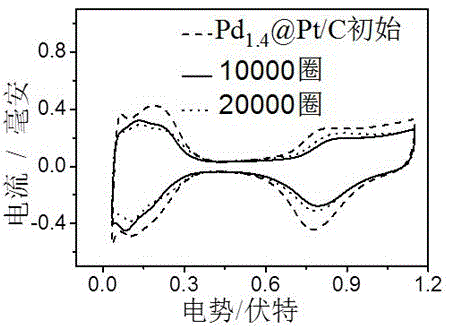

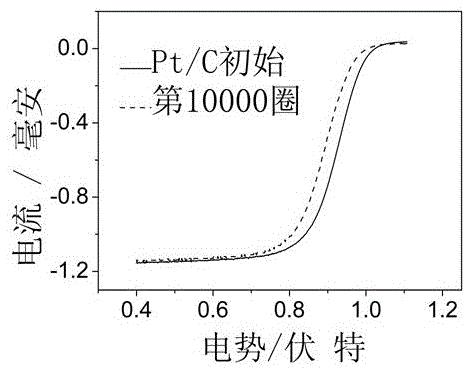

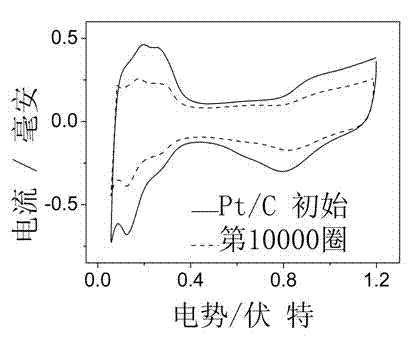

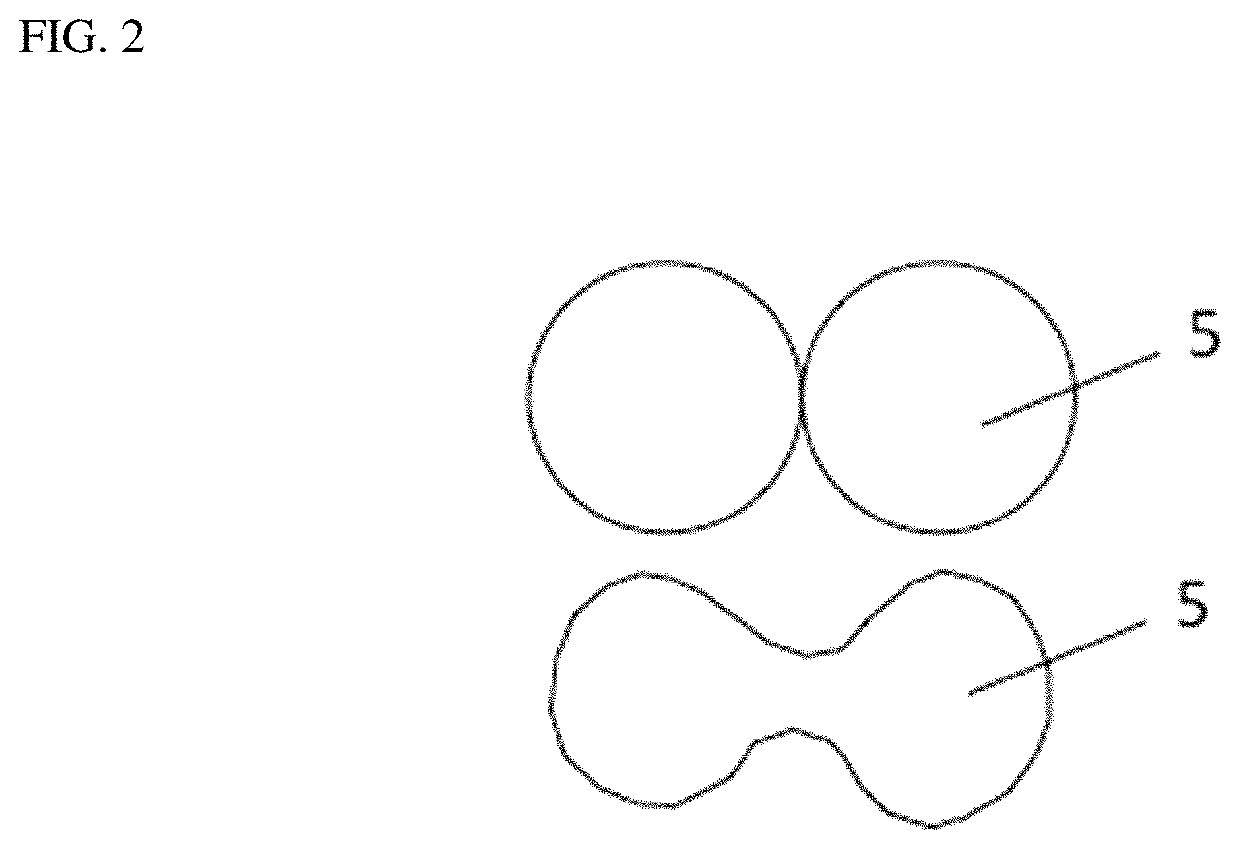

Pdx@Pt/C core-shell structure cathode catalyst for fuel cell and preparation method of Pdx@Pt/C core-shell structure cathode catalyst

ActiveCN105633425AEasy to prepareSolve resource problemsMaterial nanotechnologyCell electrodesPrimary cellAniline

The invention discloses a Pdx@Pt / C core-shell structure cathode catalyst for a fuel cell and a preparation method of the Pdx@Pt / C core-shell structure cathode catalyst. The method comprises the following steps: (1) adding a palladium precursor and a conductive carrier to N,N-dimethyl formamide or ethanol, carrying out ultrasonic mixing, and then adding borane.N,N-diethyl aniline or sodium borohydride, reacting at a room temperature for 0.5-1.5h, carrying out centrifugal washing and vacuum drying and then obtaining a carbon-supported Pd catalyst, namely Pd / C; and (2) ultrasonically dispersing the Pd / C prepared in the step (1) into a formic acid solution with the concentration of 1-5ml formic acid / 20ml water, adding a water solution of a platinum compound at the atomic ratio of Pt to Pd being 1 to 1 or 1 to 2 or 1 to 3, reacting at the room temperature for 2-6h, and carrying out centrifugal washing and vacuum drying to obtain the product. The catalyst with high catalytic activity and stability is prepared by a primary cell reaction principle; the catalyst is lower than a pure Pt catalyst in cost; the preparation method is simple, convenient, mild in condition and easy to operate; and the problem that a high temperature and a surfactant are required for preparation of the core-shell structure catalyst by a conventional chemical reduction method is solved.

Owner:WUHAN UNIV

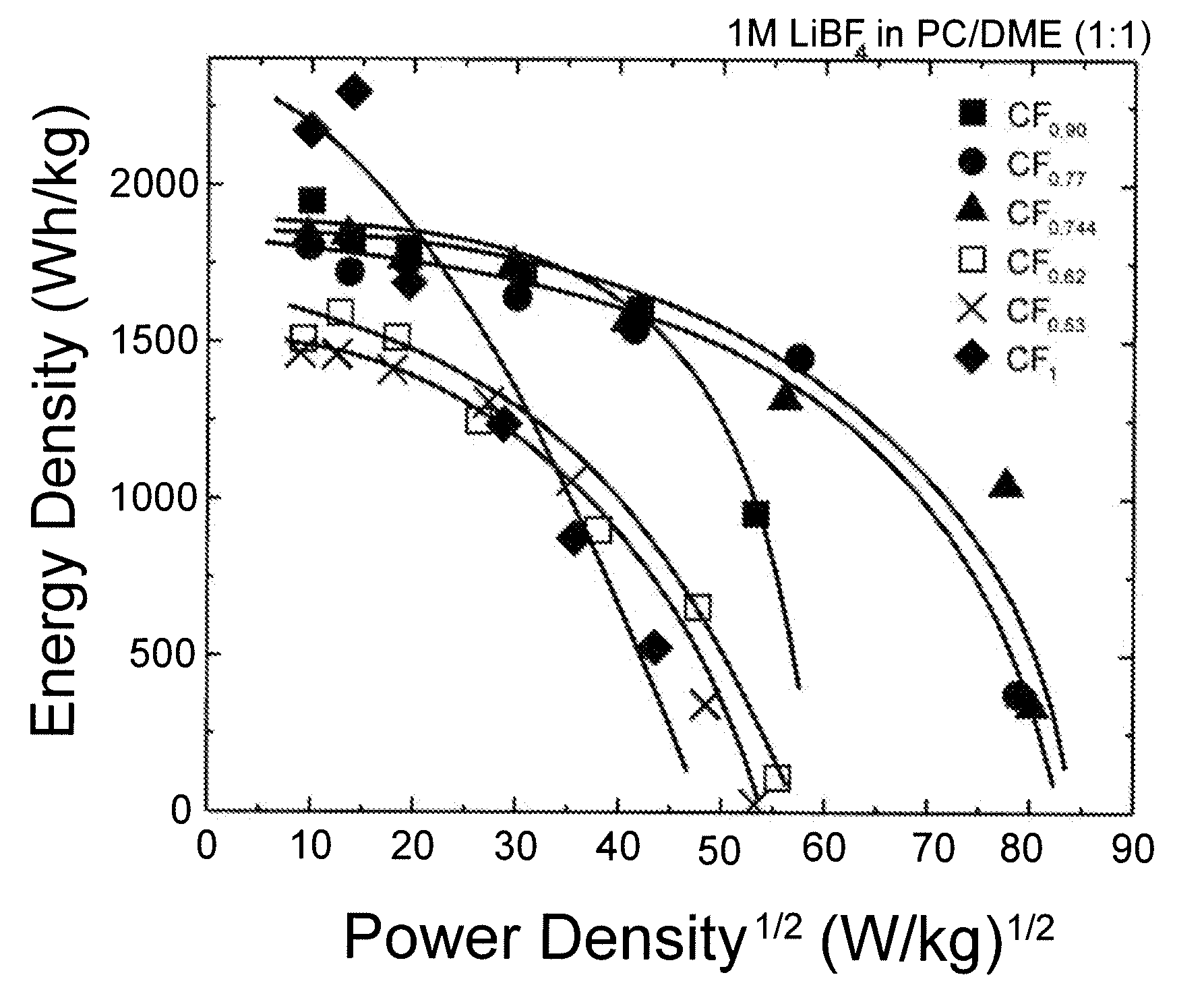

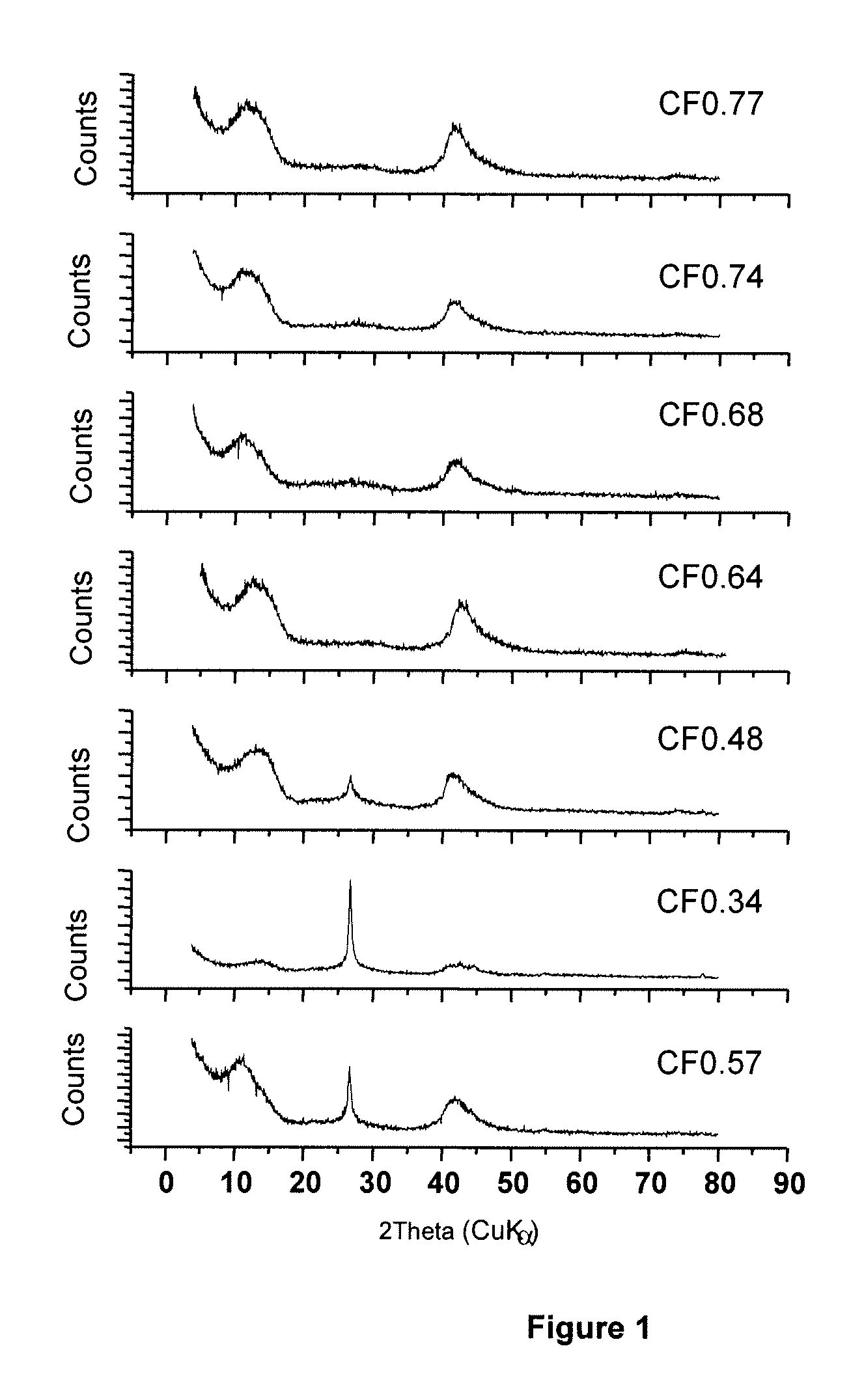

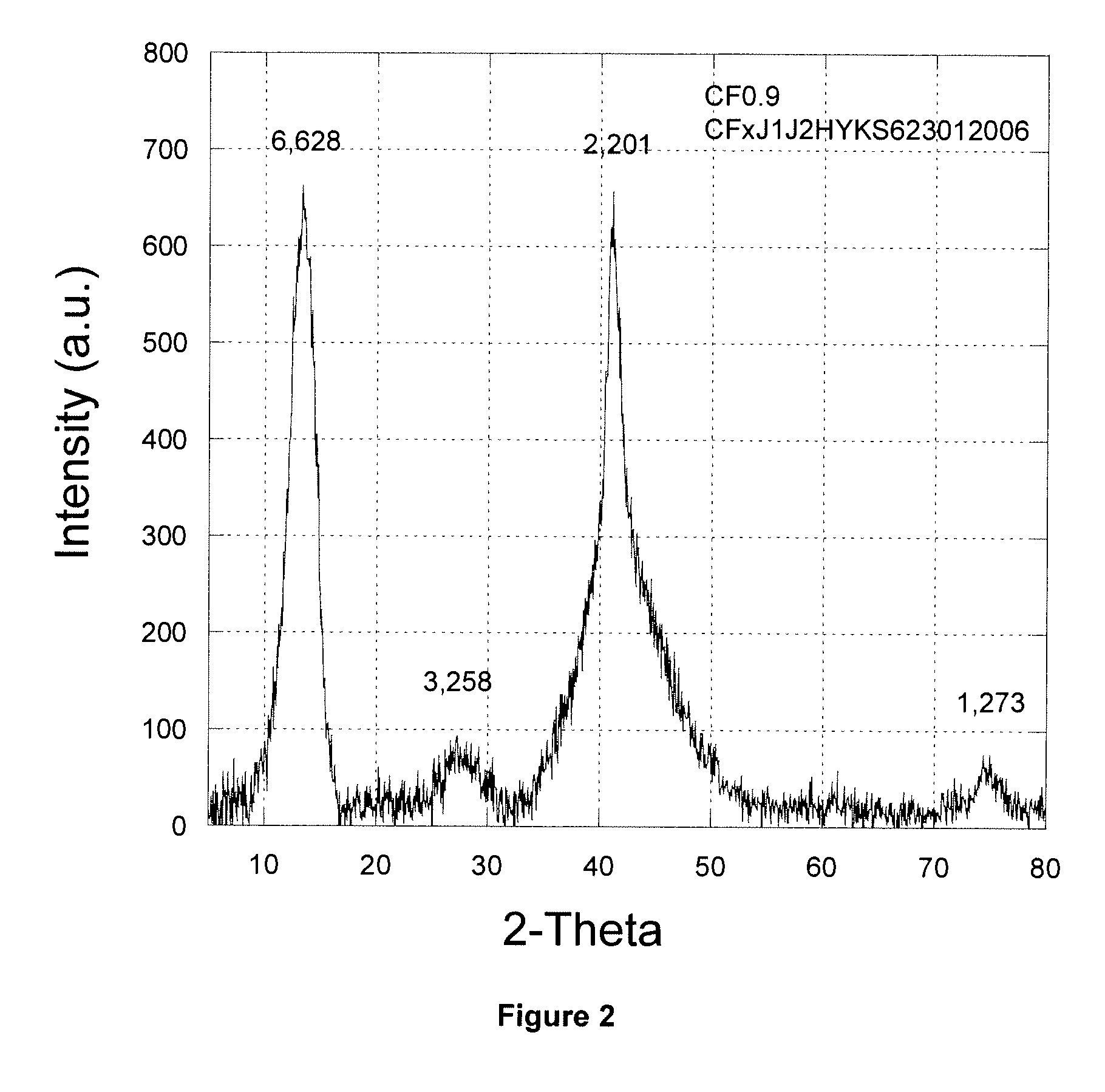

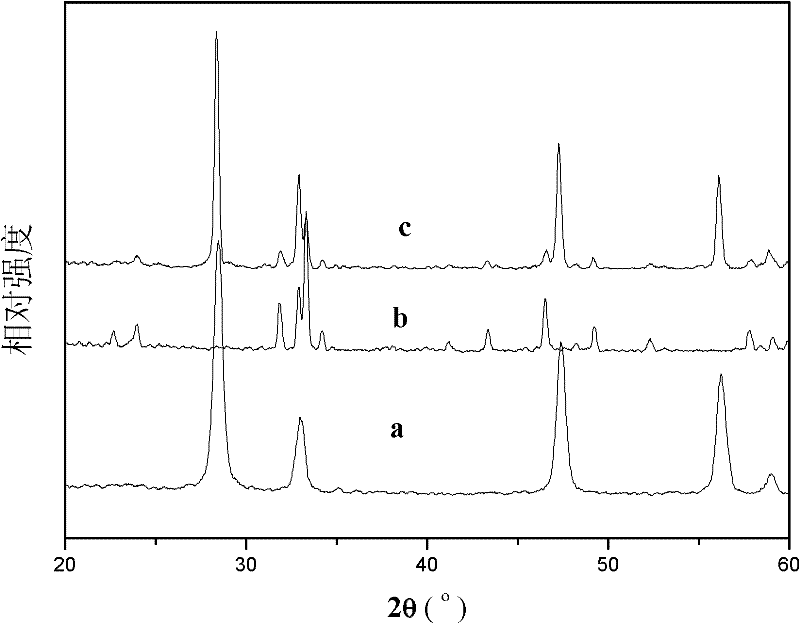

Electrochemistry of carbon subfluorides

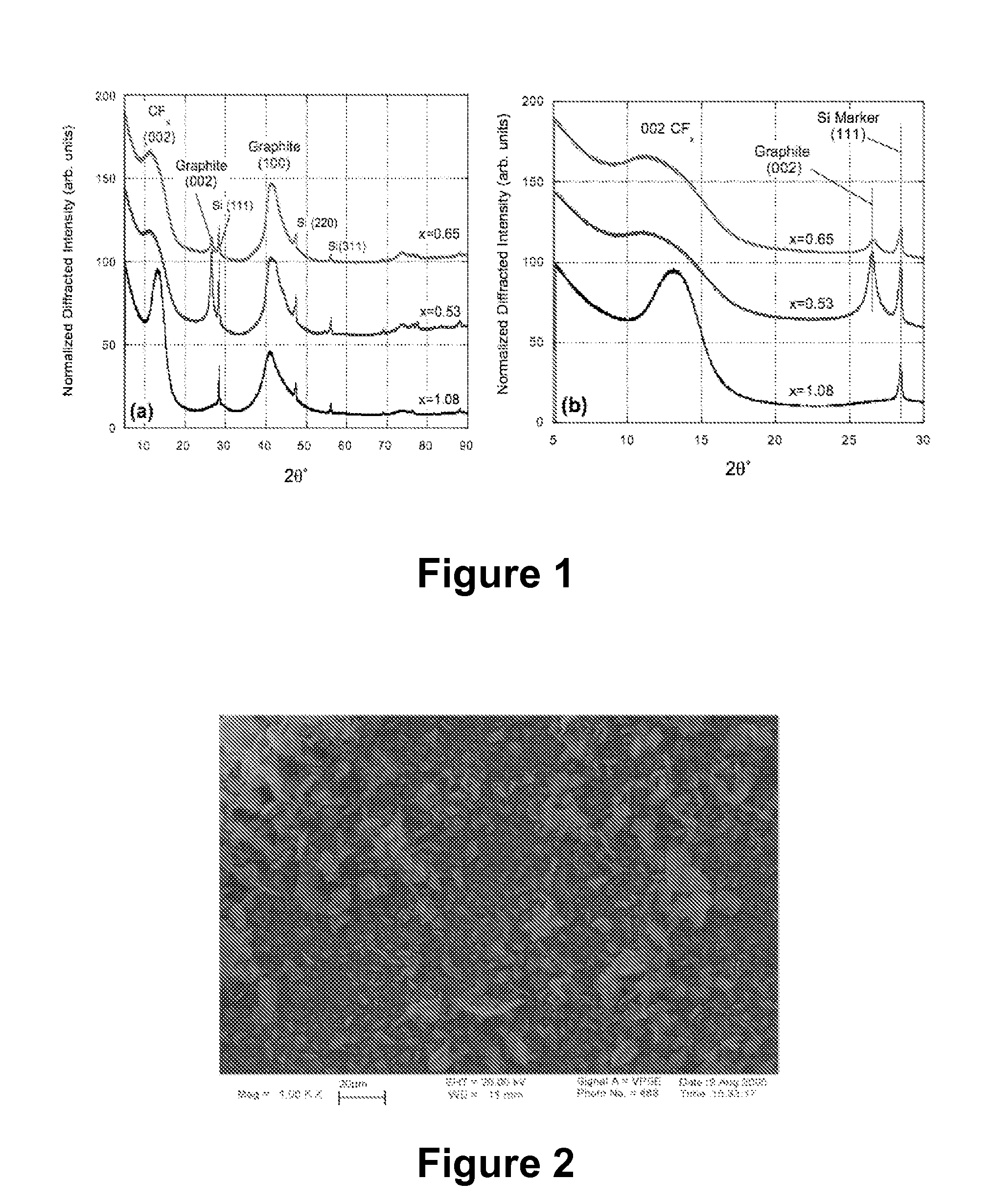

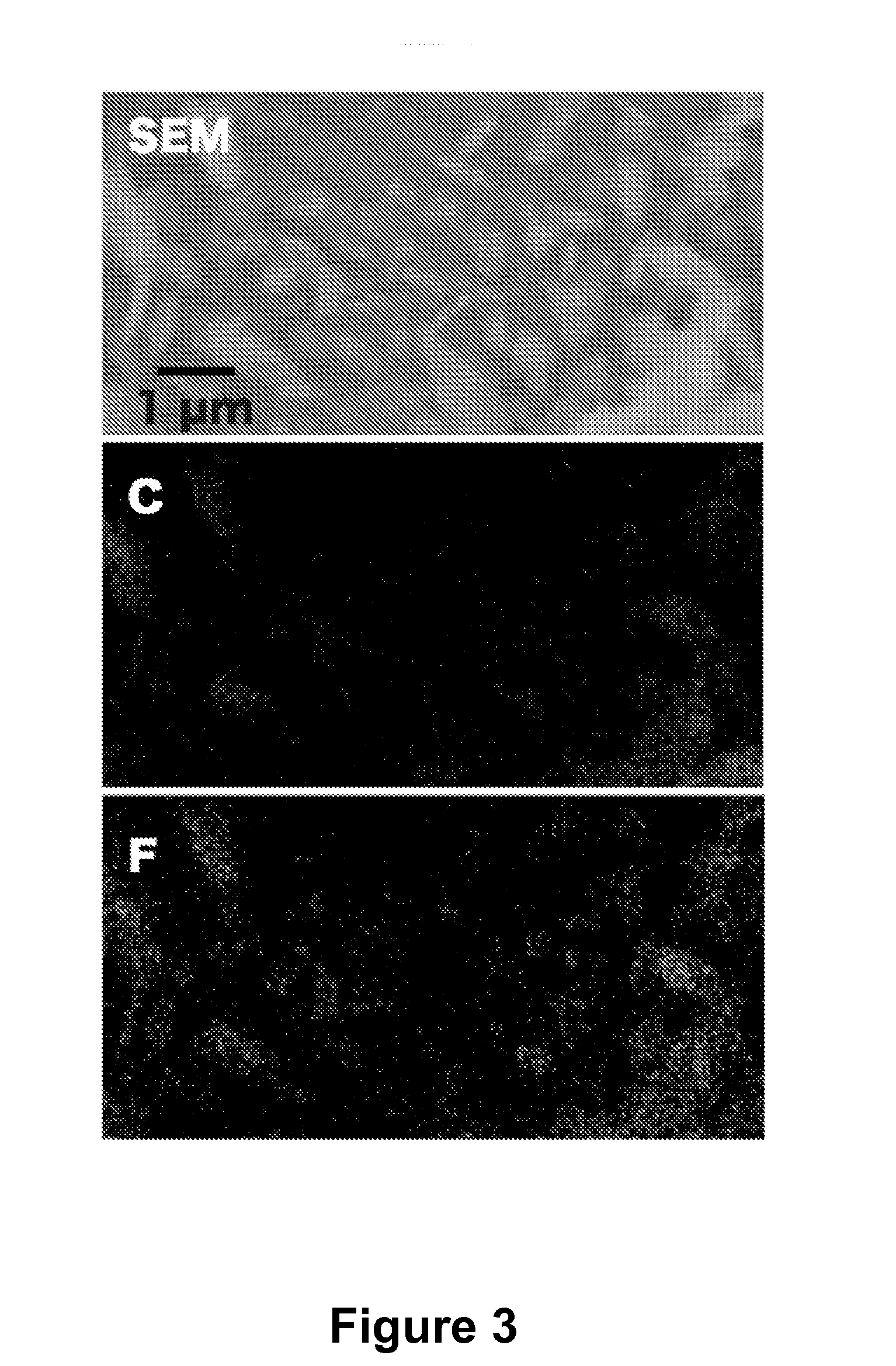

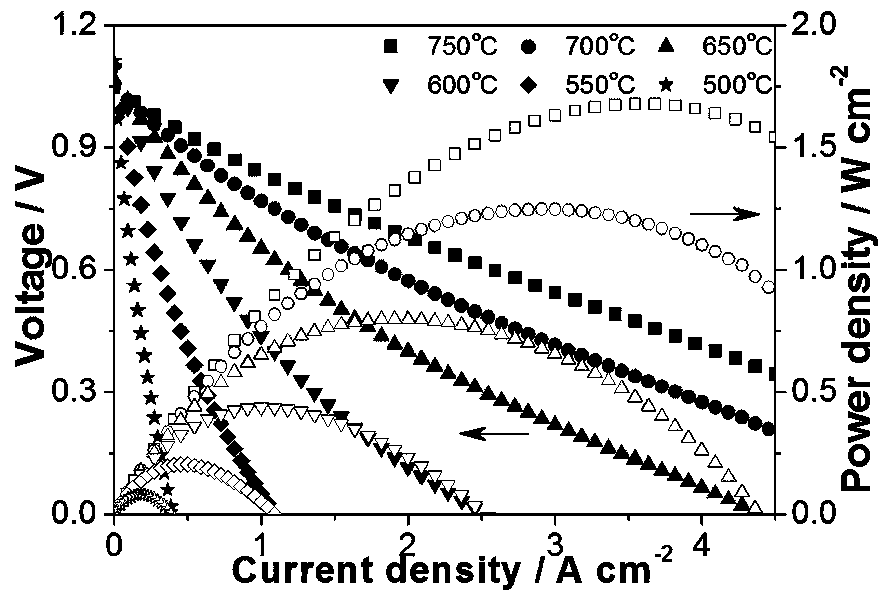

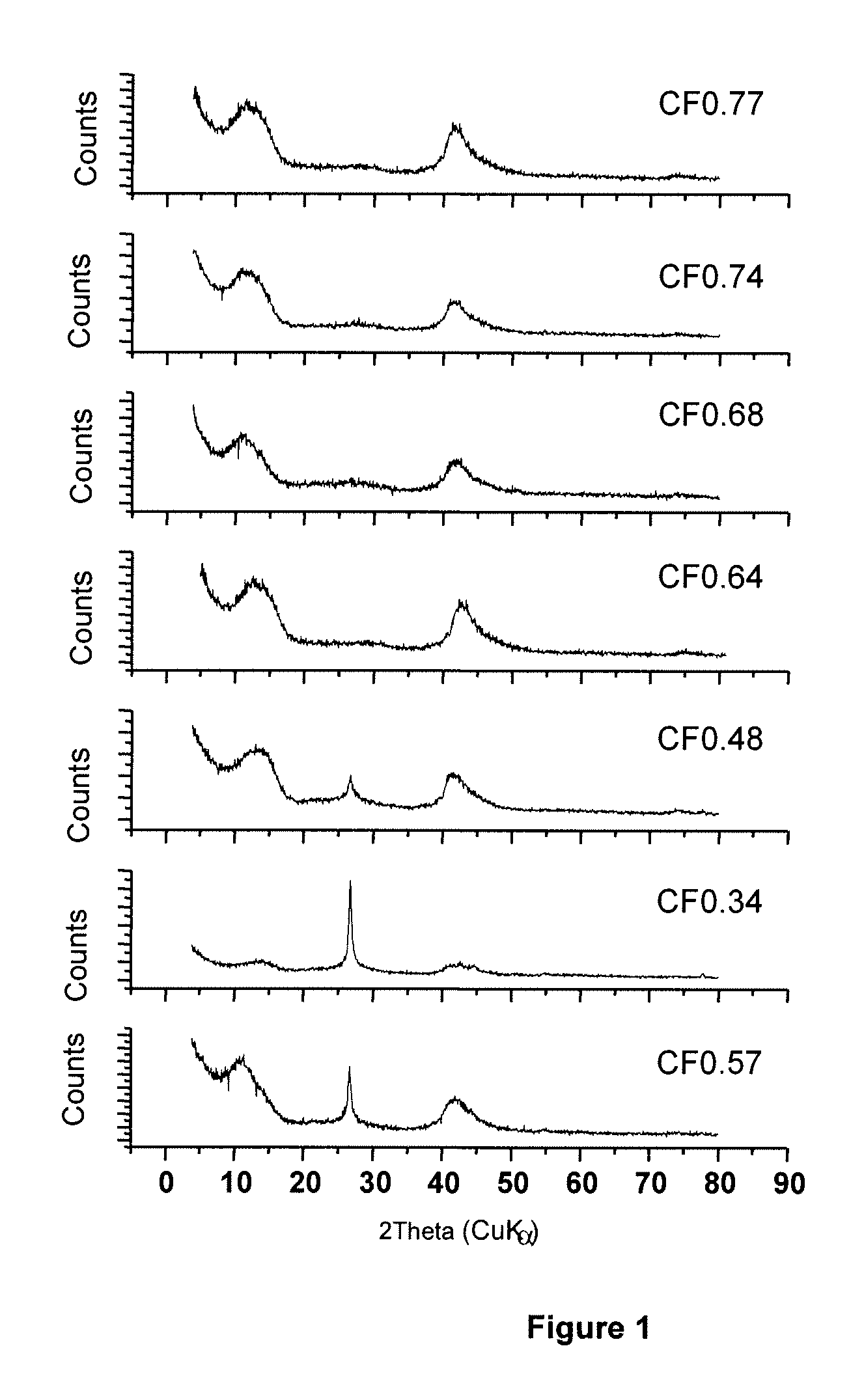

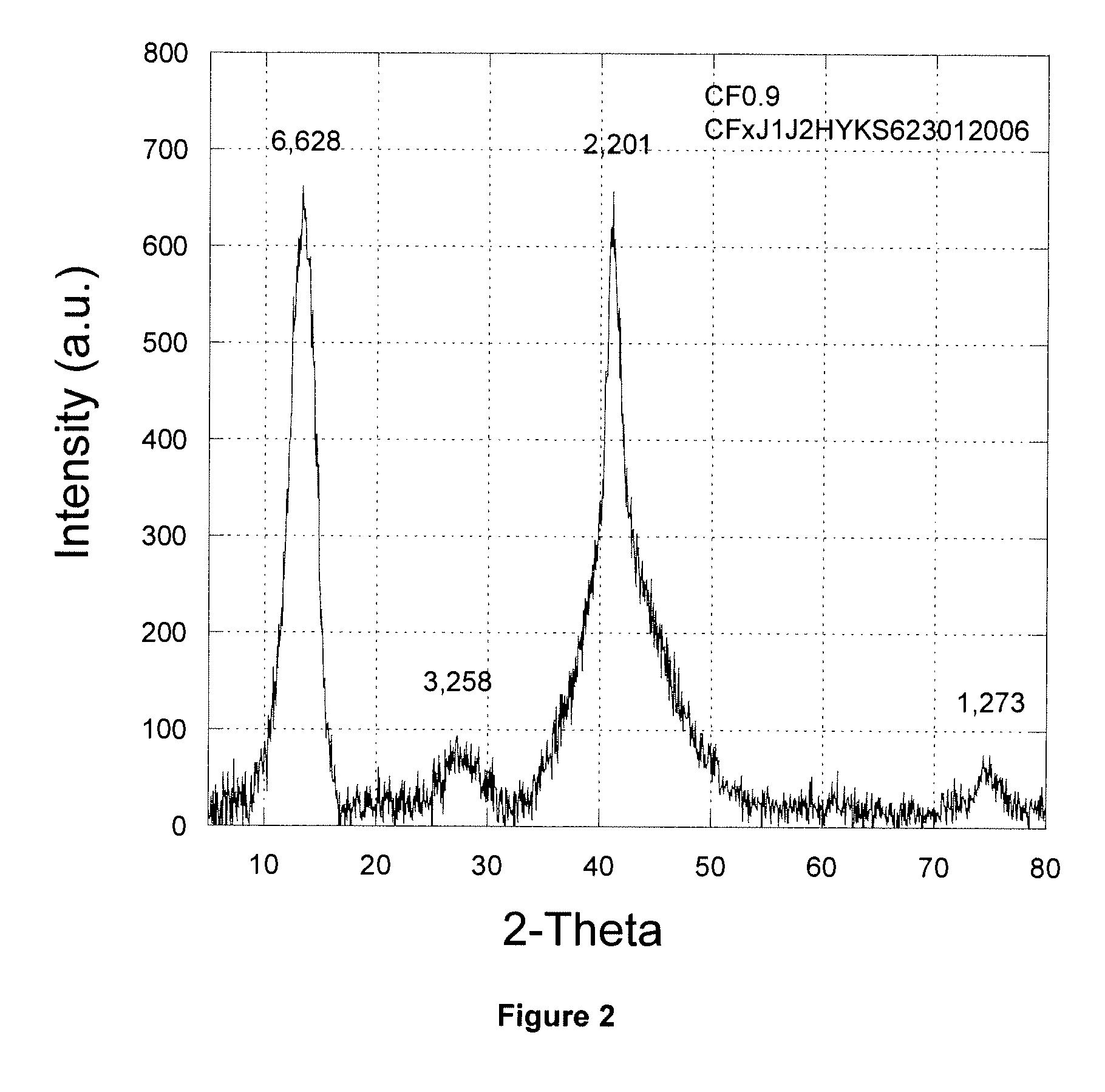

ActiveUS20070231697A1Improve cathode performanceImprove battery performanceNon-aqueous electrolyte cellsElectrode carriers/collectorsChemical compositionHigh rate

Subfluorinated carbonaceous materials obtained through direct fluorination of graphite or coke particles are provided. One set of subfluorinated carbonaceous materials has an average chemical composition CFx in which 0.63<x≦0.95, 0.66<x≦0.95 or 0.7<x≦0.95. The subfluorinated carbonaceous materials are capable of electrochemical performance superior to commercial CF at relatively high rates of discharge.

Owner:CALIFORNIA INST OF TECH +2

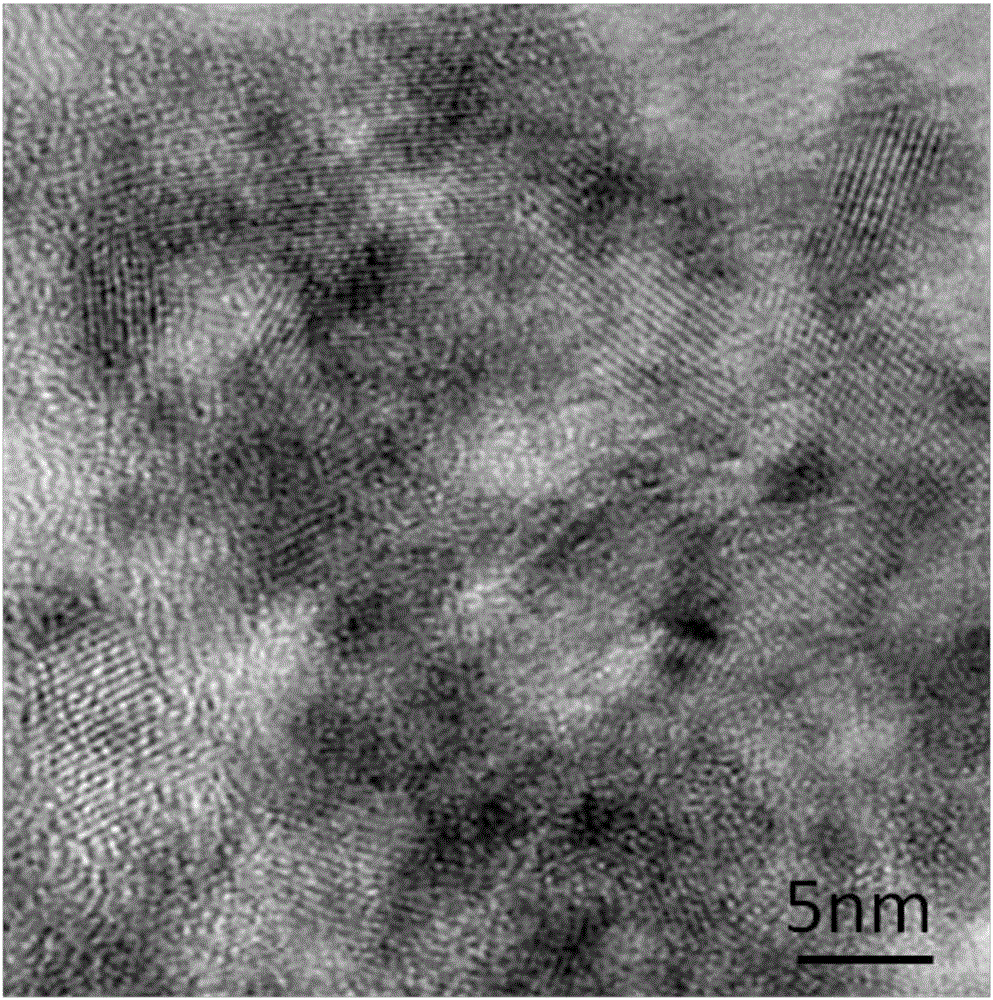

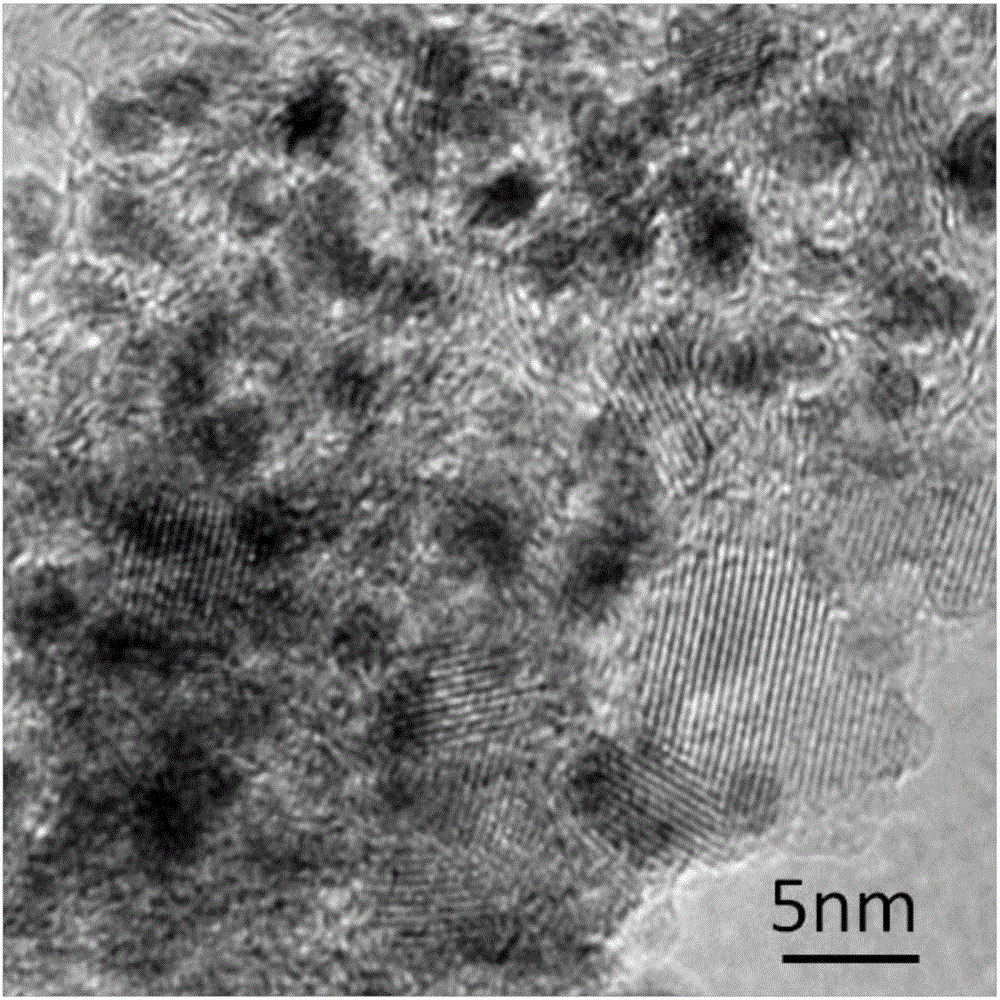

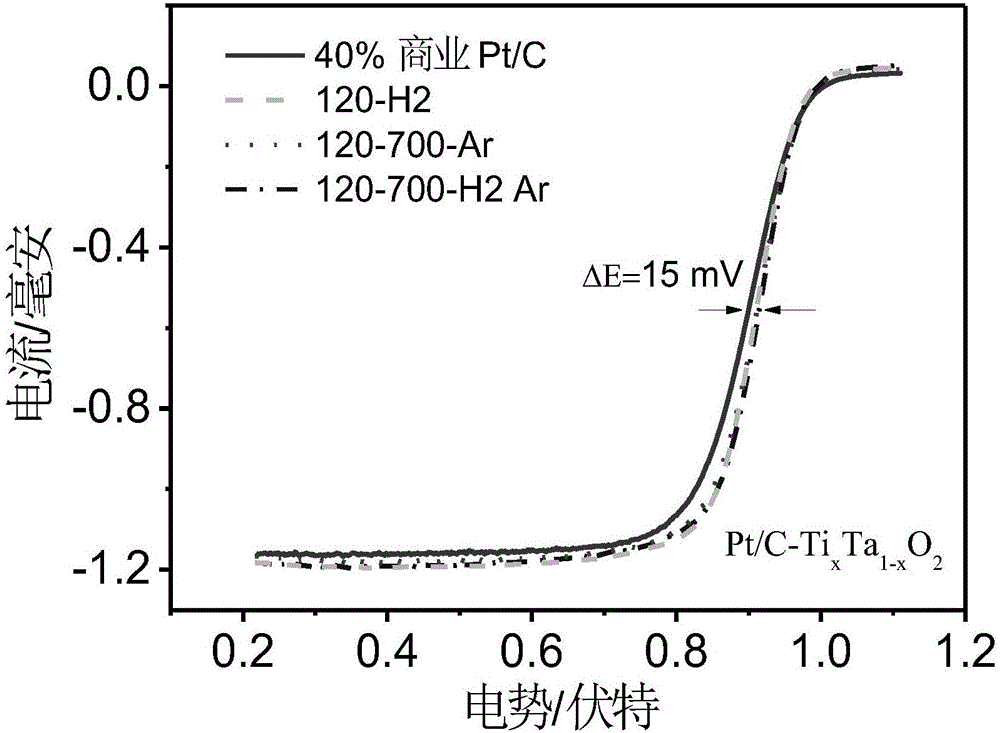

Composite oxide carbon carrier-loaded nano Pt catalyst and preparation method and application thereof

ActiveCN106505214AImprove hydrophilicityImprove conductivityMaterial nanotechnologyCell electrodesHigh surfaceComposite oxide

The invention discloses a Pt-based fuel cell cathode catalyst of a transition metal element doped with TiO2 and a carbon compound with high specific surface area as a carrier, and a preparation method of the Pt-based fuel cell cathode catalyst. The method comprises the steps of adding a Ti compound and a transition metal M precursor to water, adding carbon with high specific surface area, carrying out ultrasonic mixing evenly and then obtaining a composite oxide carbon carrier C-Ti<x>M<1-x>O<2> by using a hydrothermal method; and mixing a platinum compound water solution with the C-Ti<x>M<1-x>O<2> and obtaining a composite oxide carbon carrier-loaded nano Pt catalyst, namely a Pt / C-Ti<x>M<1-x>O<2> catalyst by adopting an impregnation method. Compared with commercial Pt / C, the prepared Pt / C-Ti<x>M<1-x>O<2> catalyst has higher catalytic activity and stability due to interaction between a metal and the carrier; the preparation method is simple and convenient, mild in condition and easy to operate; the problems of high surface Pt agglomeration degree and poor stability of the catalyst prepared by adopting a conventional impregnation method are solved; and the composite oxide carbon carrier-loaded nano Pt catalyst is a powder catalyst suitable for a proton exchange membrane fuel cell.

Owner:WUHAN UNIV

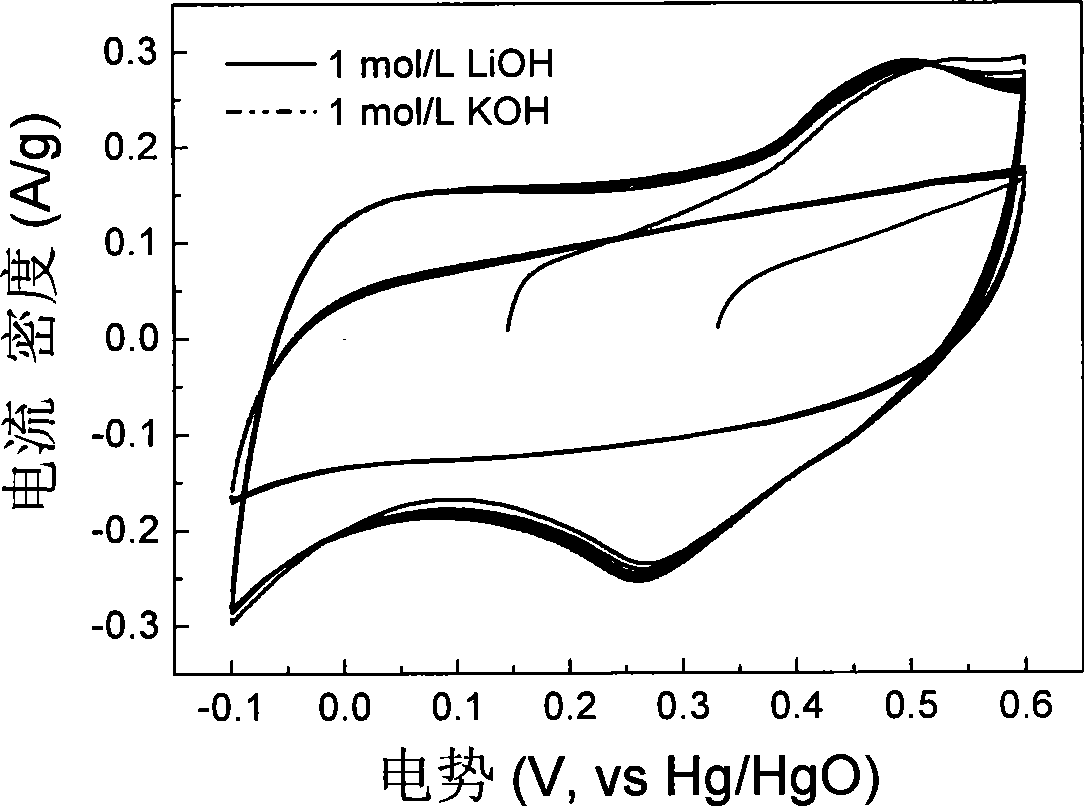

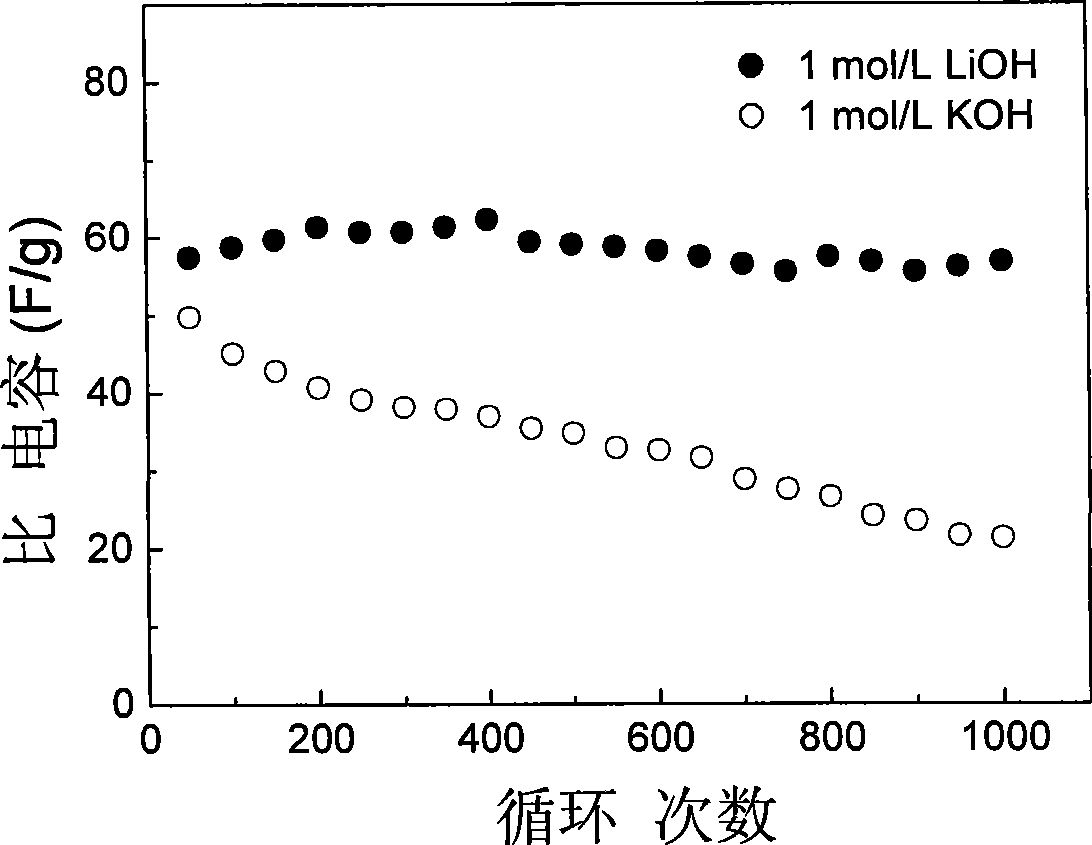

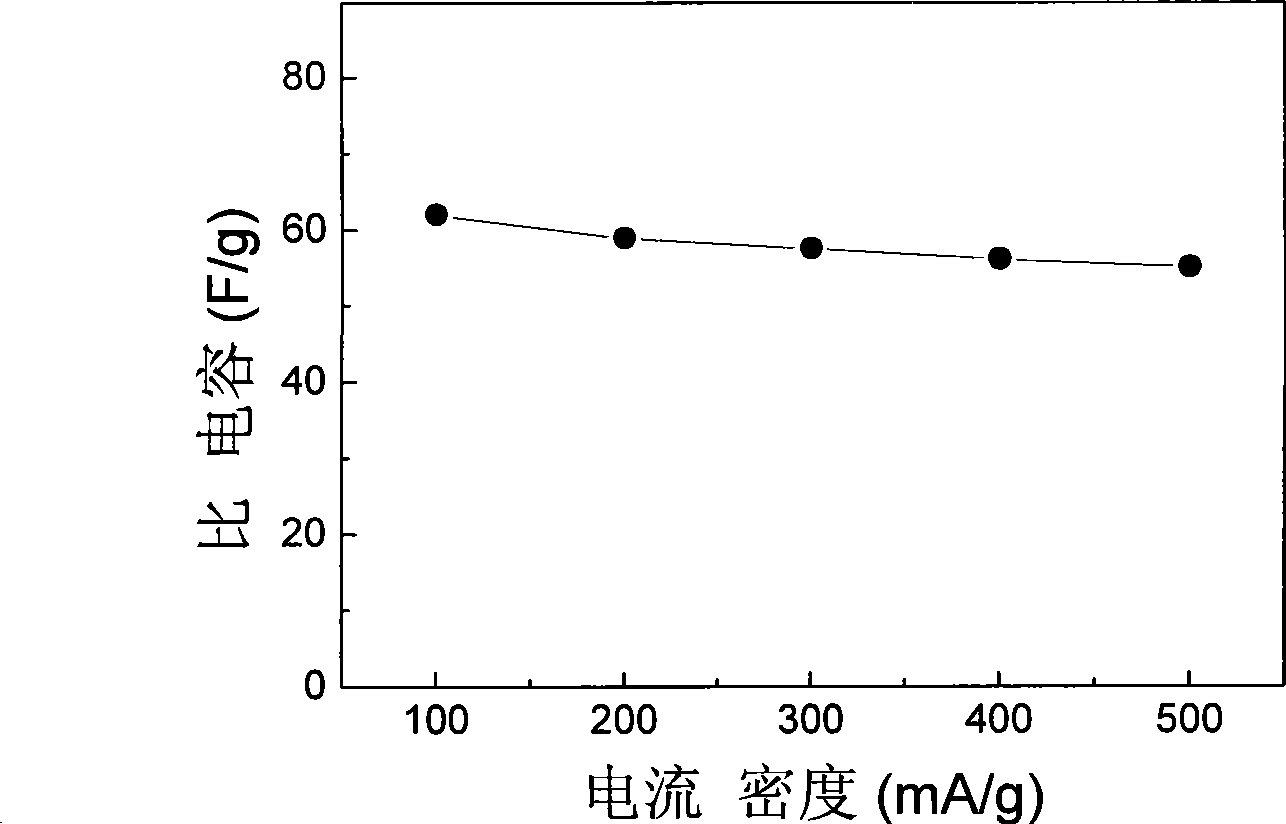

Novel mixed super capacitor

InactiveCN101399120AIncrease energy densityImprove power densityReduction and oxidation devicesCapacitanceHigh rate

The invention relates to a novel mixed super capacitor which adopts a nano MnO2 electrode as a positive electrode, an activated carbon electrode as a negative electrode and alkaline lithium hydroxide water solution as electrolyte. The positive electrode stores energy by a Faraday oxidation reduction mechanism, and the negative electrode stors energy by a double electrode layer mechanism. When the lithium hydroxide electrolyte is adopted, the reaction mechanism of the nano MnO2 electrode is different from the reaction mechanism in potassium hydroxide electrolyte or neutral water solution. Therefore, the nano MnO2 electrode has higher specific capacitance. The super capacitor has the advantages of perfect high energy intensity, high power intensity, high-rate charge and discharge performance, long circulation service life, low cost and no environmental damages and can be applied to large power charge and discharge occasions.

Owner:SHANGHAI UNIV

Method of producing lithium ion cathode materials

InactiveUS20090230349A1High densityReduce irreversible capacityElectrode manufacturing processesCobalt compoundsLithium-ion batteryAlkali metal

A method of producing Liy[NixCo1−2xMnx]O2 wherein 0.025≦x≦0.5 and 0.9≦y≦1.3. The method includes mixing [NixCo1−2xMnx]OH2 with LiOH or Li2CO3 and one or both of alkali metal fluorides and boron compounds, preferably one or both of LiF and B2O3. The mixture is heated sufficiently to obtain a composition of Liy[NixCo1−2xMnx]O2 sufficiently dense for use in a lithium-ion battery cathode. Compositions so densified exhibit a minimum reversible volumetric energy characterized by the formula [1833−333x] measured in Wh / L.

Owner:3M INNOVATIVE PROPERTIES CO

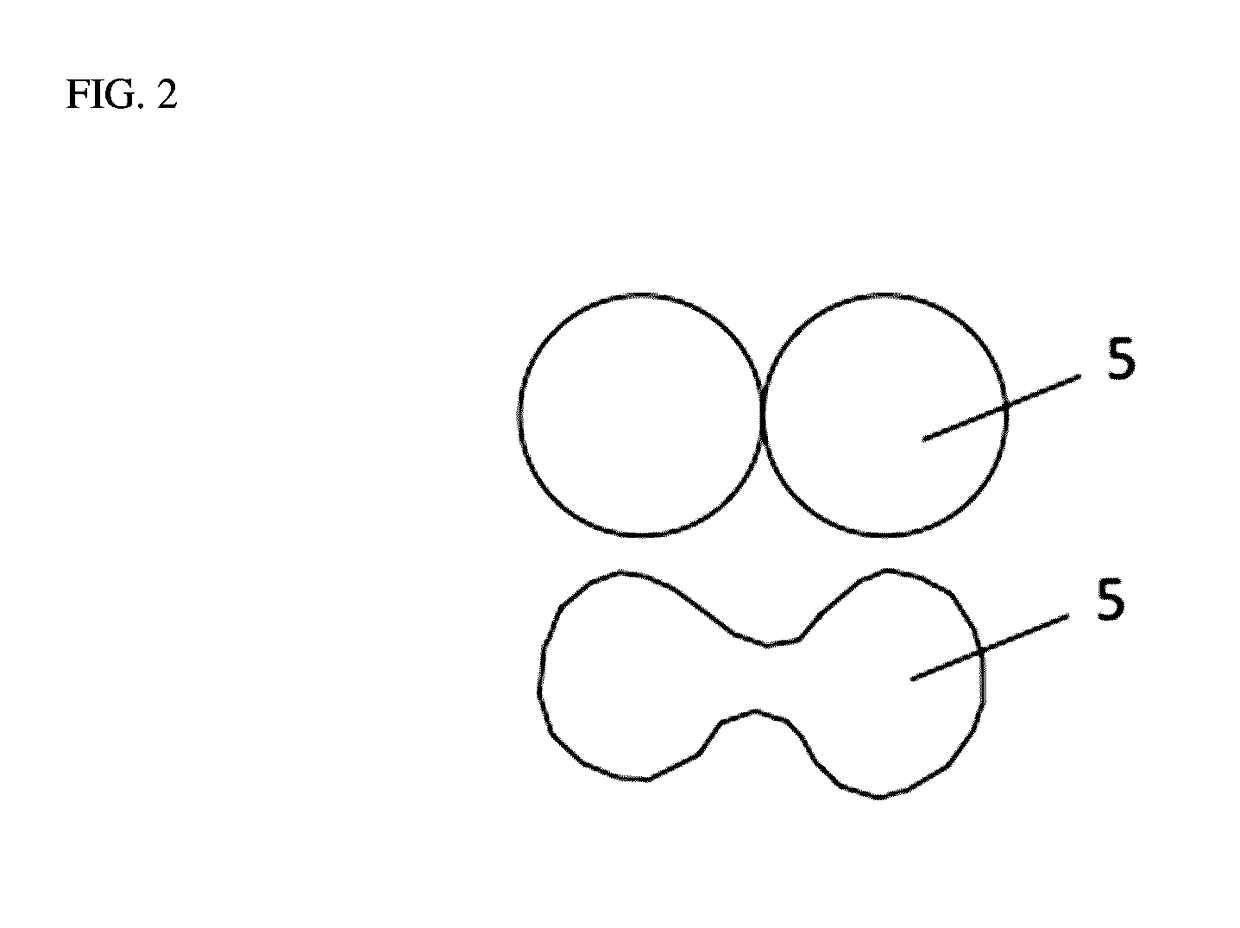

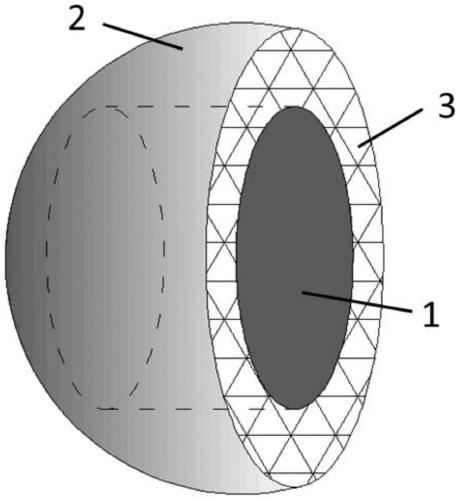

Lithium battery cathode

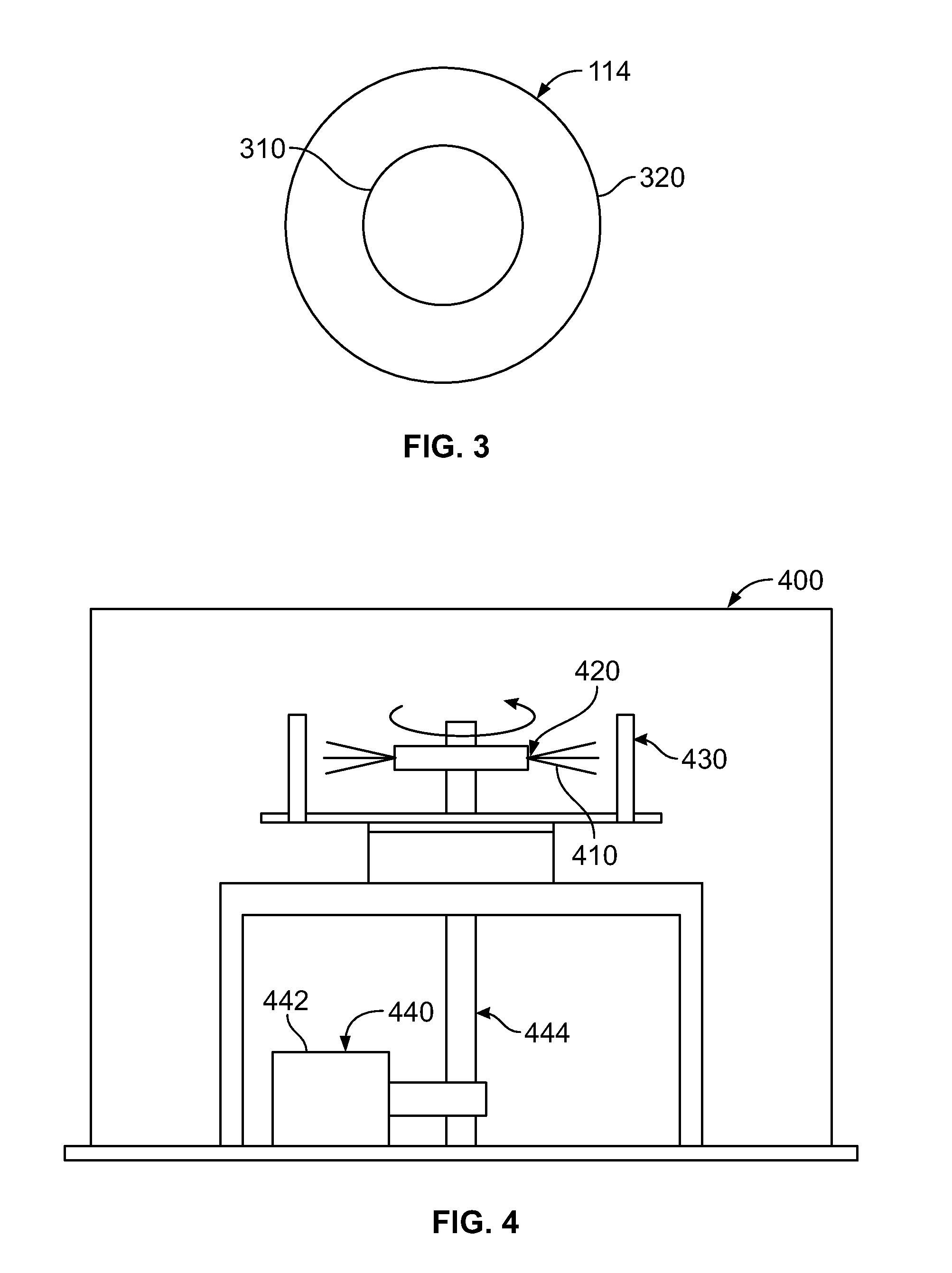

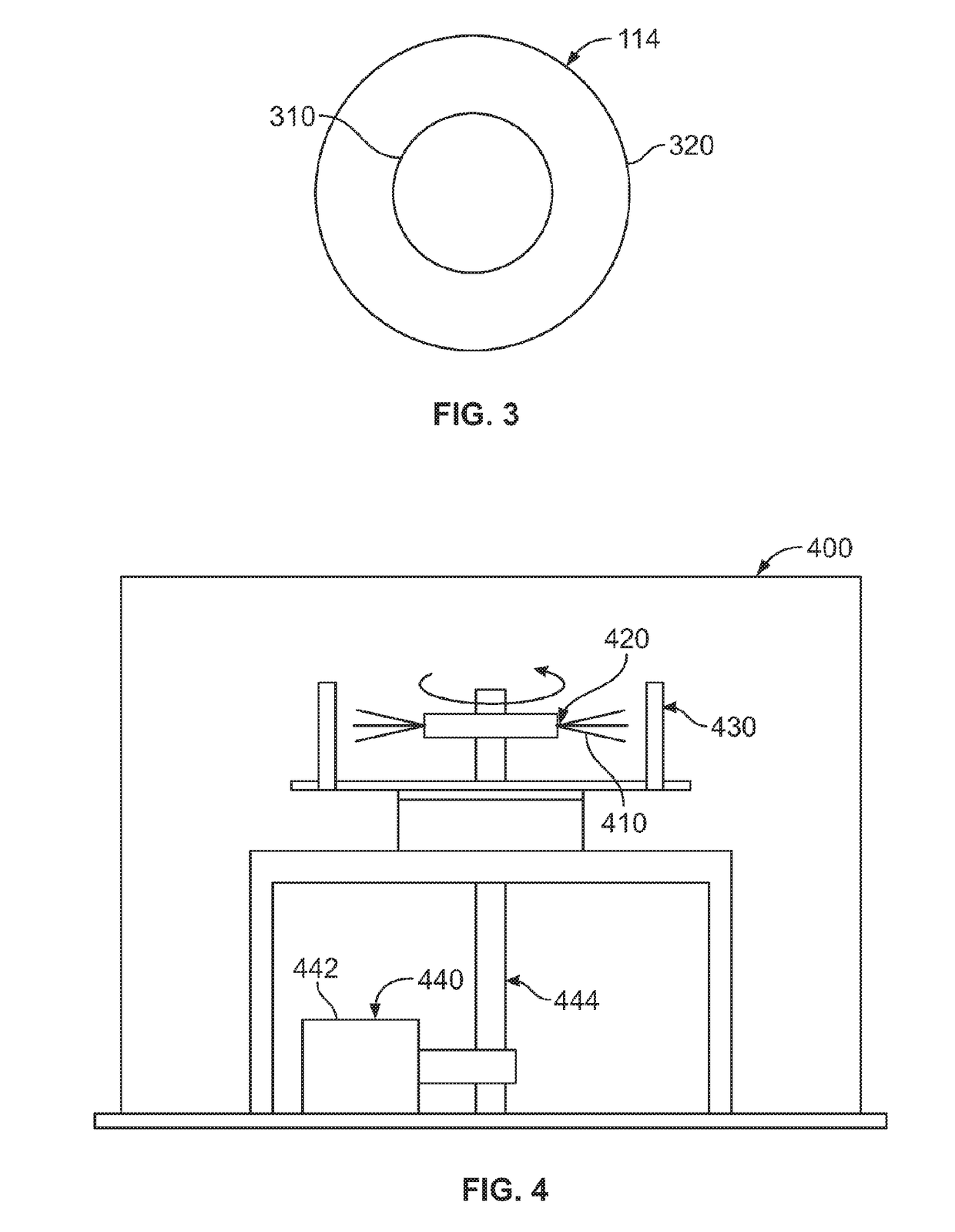

ActiveUS20150118565A1Prevents cathode degradationPrevents capacity cycling lossElectrode thermal treatmentConfectioneryElectrical batteryLithium electrode

A novel lithium battery cathode, a lithium ion battery using the same and processes and preparation thereof are disclosed. The battery cathode is formed by force spinning. Fiber spinning allows for the formation of core-shell materials using material chemistries that would be incompatible with prior spinning techniques. A fiber spinning apparatus for forming a coated fiber and a method of forming a coated fiber are also disclosed.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

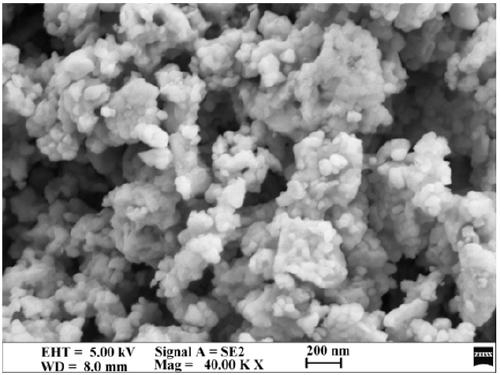

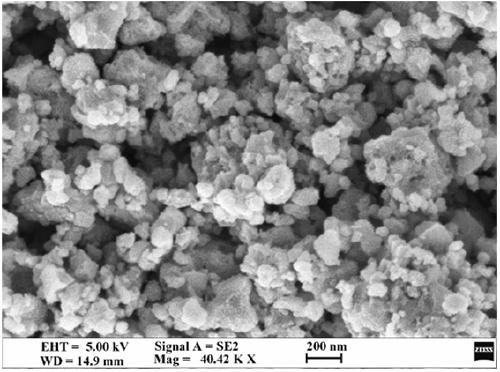

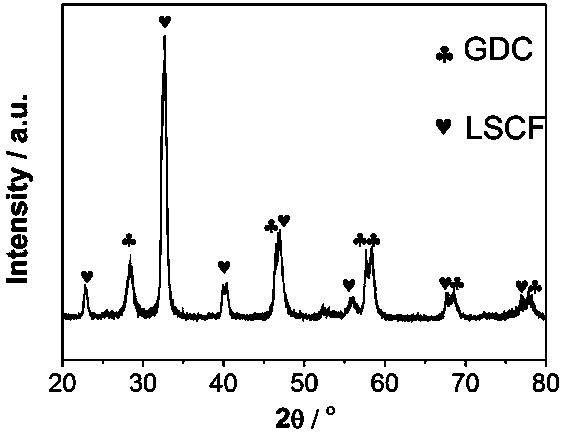

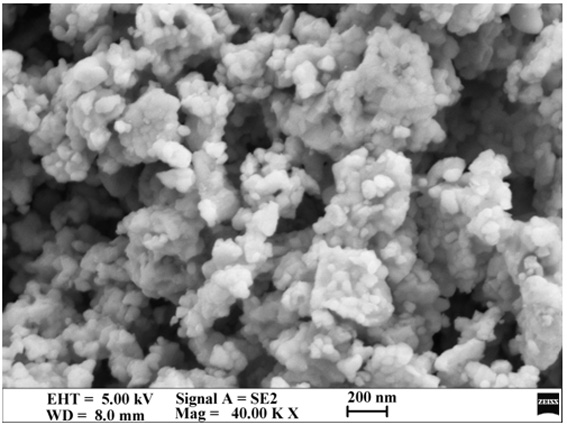

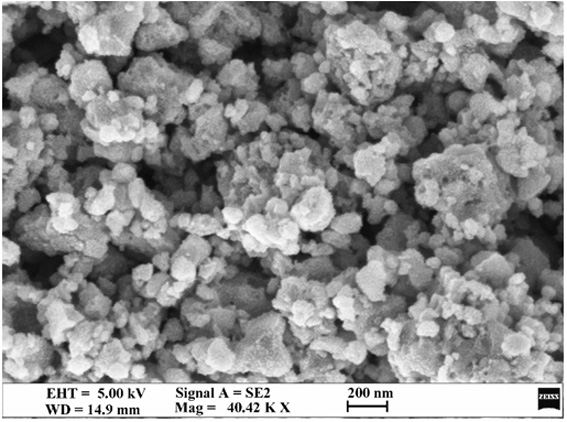

Preparation method of composite cathode material for fuel cell

ActiveCN111146456AIncrease the reaction areaImprove cathode performanceMaterial nanotechnologyCell electrodesComposite cathodeFuel cells

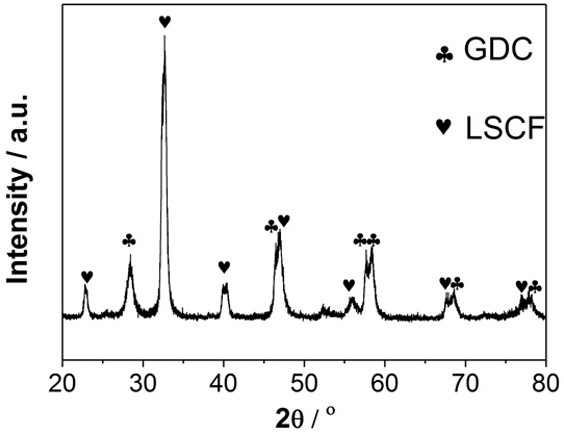

The invention discloses a preparation method of a composite cathode material for a fuel cell, and belongs to the technical field of preparation of fuel cell electrode materials. The performance of LaxSr<1-x>CoyFe<1-y>O<3-delta> (x is 0-1, and y is 0-1) is compositely enhanced through GdzCe<1-z>O2 (z is 0-1). The cathode particles obtained by the invention greatly improve the original structure, and can show significant high catalytic activity. The preparation raw materials are simple and easy to obtain, the process is stable, and the requirement of industrial production can be met.

Owner:FUZHOU UNIV

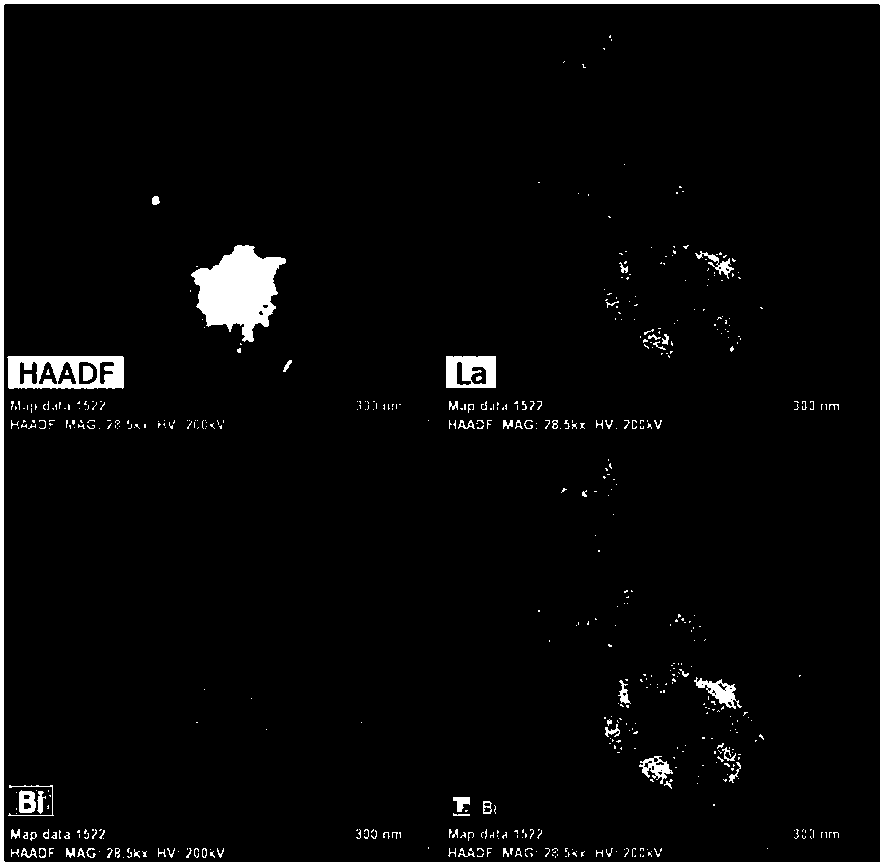

Method for preparing high-performance fuel cell nanocomposite cathode material

InactiveCN109449453AImprove performanceImprove electrochemical performanceMaterial nanotechnologyCell electrodesMaterials preparationFuel cells

The present invention discloses a method for preparing a high-performance fuel cell nanocomposite cathode material, and belongs to the technical field of fuel cell catalytic material preparation. Thefeed stocks comprise: doped bismuth oxide, a complexing agent, La(NO3)3.6H2O, Sr(NO3)2, Mn(NO3)2 and ammonium hydroxide. The molar ratio of La(NO3)3.6H2O, Sr(NO3)2, and Mn(NO3)2 is (0.4-0.9): (0.1-0.6): (0.8-1.2); and the complexing agent is a mixture of citric acid and EDTA. The high-performance fuel cell nanocomposite cathode is successfully obtained by modifying the doped bismuth oxide by usinga sol-gel method. The composite cathode particles obtained by using the method disclosed by the present invention can reach a nanometer size and can exhibit remarkable high catalytic activity; and the feed stocks in the present invention is simple and available, the process is stable, and the industrialized conditions are achieved.

Owner:FUZHOU UNIV

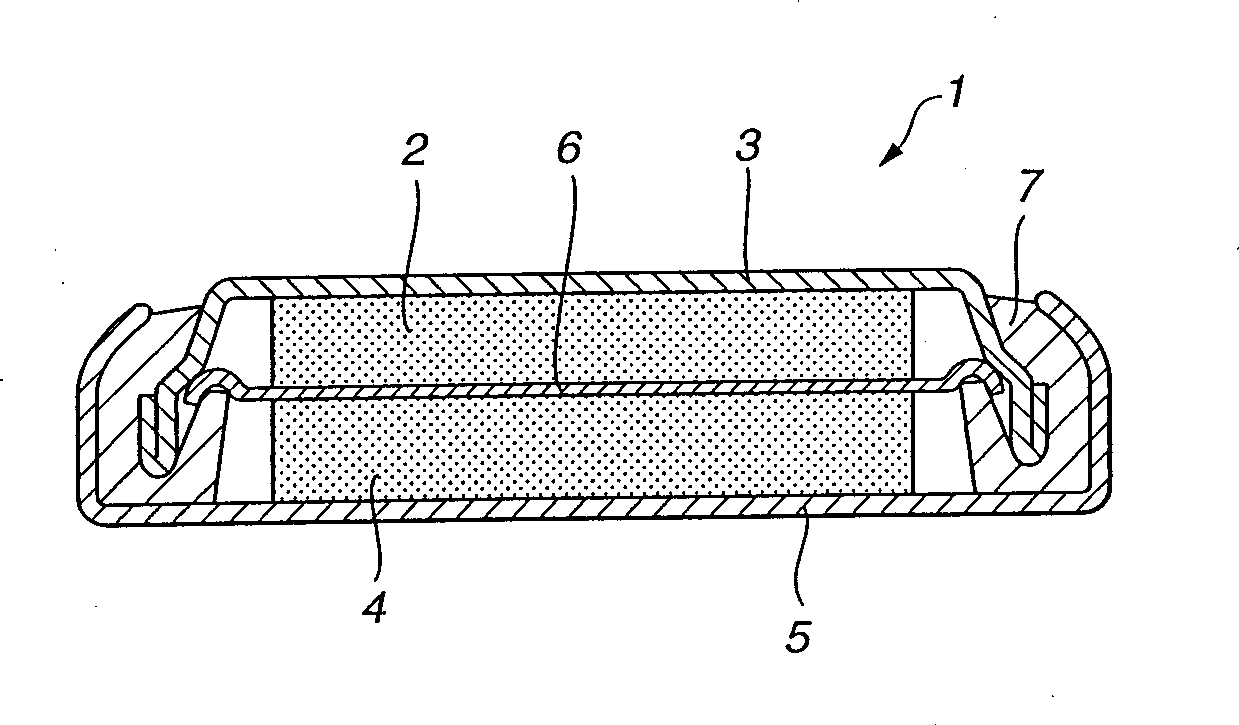

Method for producing cathode active material and method for manufacturing nonaqueous electrolyte cell

InactiveCN1189959CImprove cathode performanceImprove performanceElectrode manufacturing processesNon-aqueous electrolyte accumulatorsManganeseLithium manganese oxide

A method for producing a cathode active material which produces a spinel type lithium manganese oxide expressed by a general formula: Li1+xMn2-x-yMeyPO4, as the cathode active material, (here, x is expressed by a relation of 0<=x<=0.15 and y is expressed by a relation of 0 C01D 15 / 02 H01M 4 / 04 1 19 31 2001 / 10 / 23 1350339 2002 / 5 / 22 1189959 2005 / 2 / 16 2005 / 2 / 16 2005 / 2 / 16 Sony Corp. Japan Sakai Hideki Fukuba Shigeshi Takahashi Kimio wang jie 11038 The Patent Agency of the Chinese Council for the Promotion of International Trade (CCPIT) No.1 Waidajie, Fuxingmen, Beijing 100086 Japan 2000 / 10 / 23 323214 / 2000

Owner:SONY CORP

Electrochemistry of carbon subfluorides

ActiveUS8232007B2Improve cathode performanceHigh rateNon-aqueous electrolyte cellsElectrode carriers/collectorsHigh rateChemical composition

Subfluorinated carbonaceous materials obtained through direct fluorination of graphite or coke particles are provided. One set of subfluorinated carbonaceous materials has an average chemical composition CFx in which 0.63<x≦0.95, 0.66<x≦0.95 or 0.7<x≦0.95. The subfluorinated carbonaceous materials are capable of electrochemical performance superior to commercial CF at relatively high rates of discharge.

Owner:CALIFORNIA INST OF TECH +2

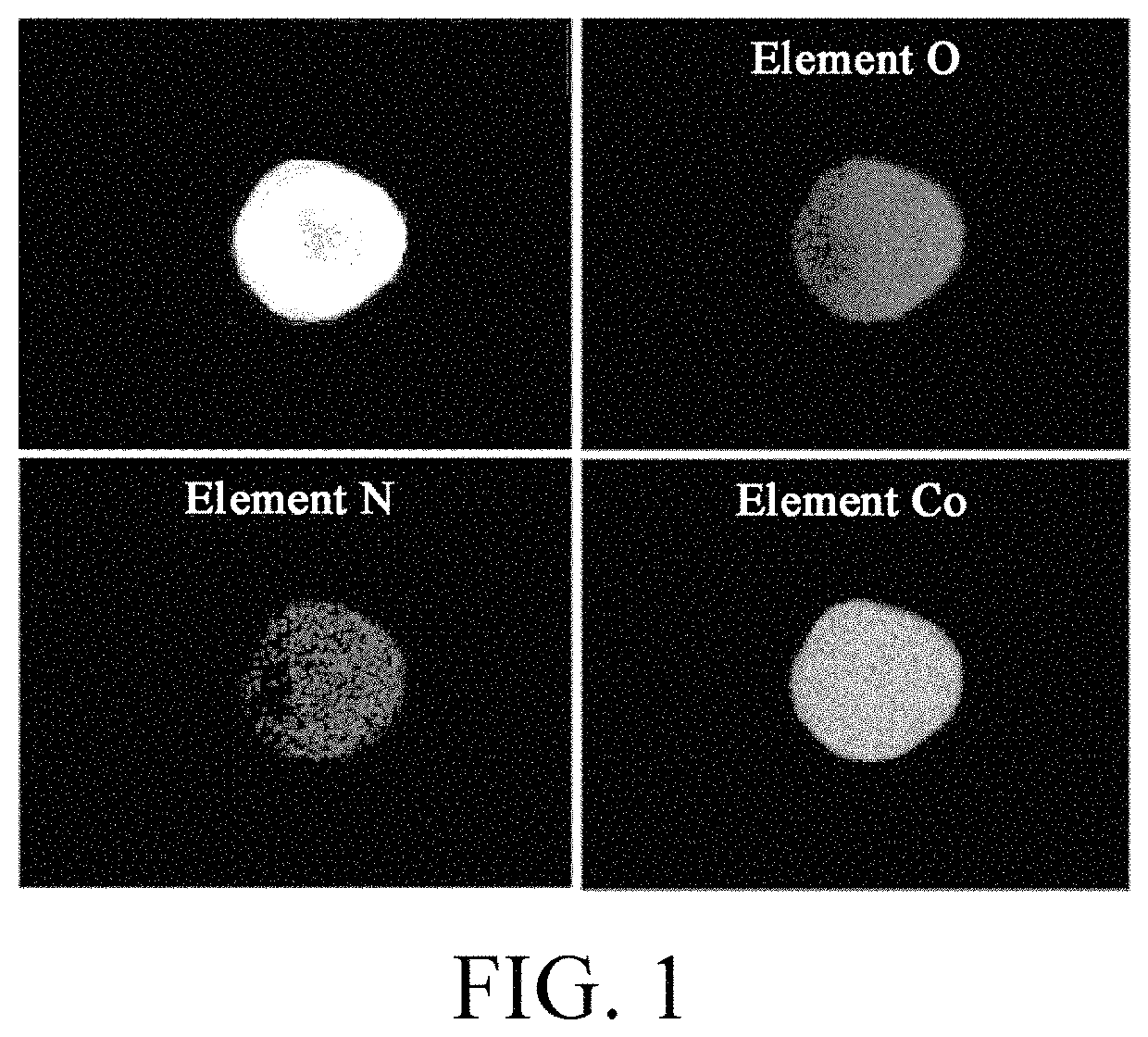

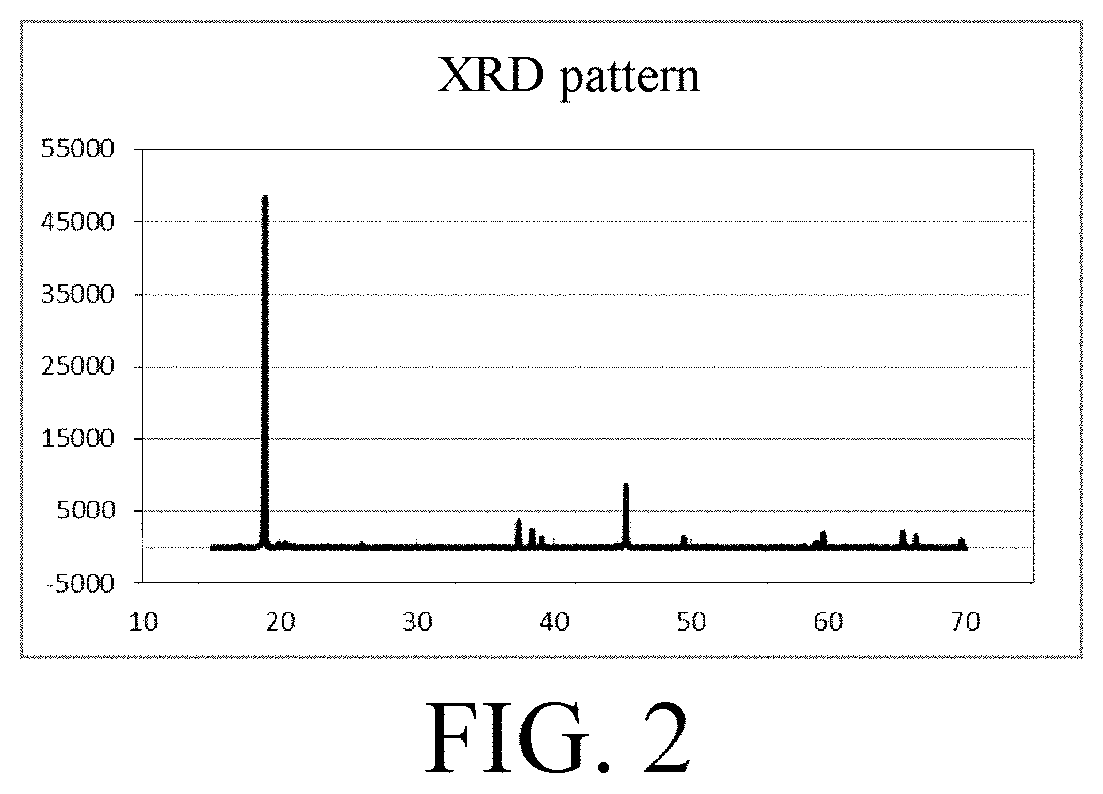

Metal oxide and synthesis of lithium ion battery

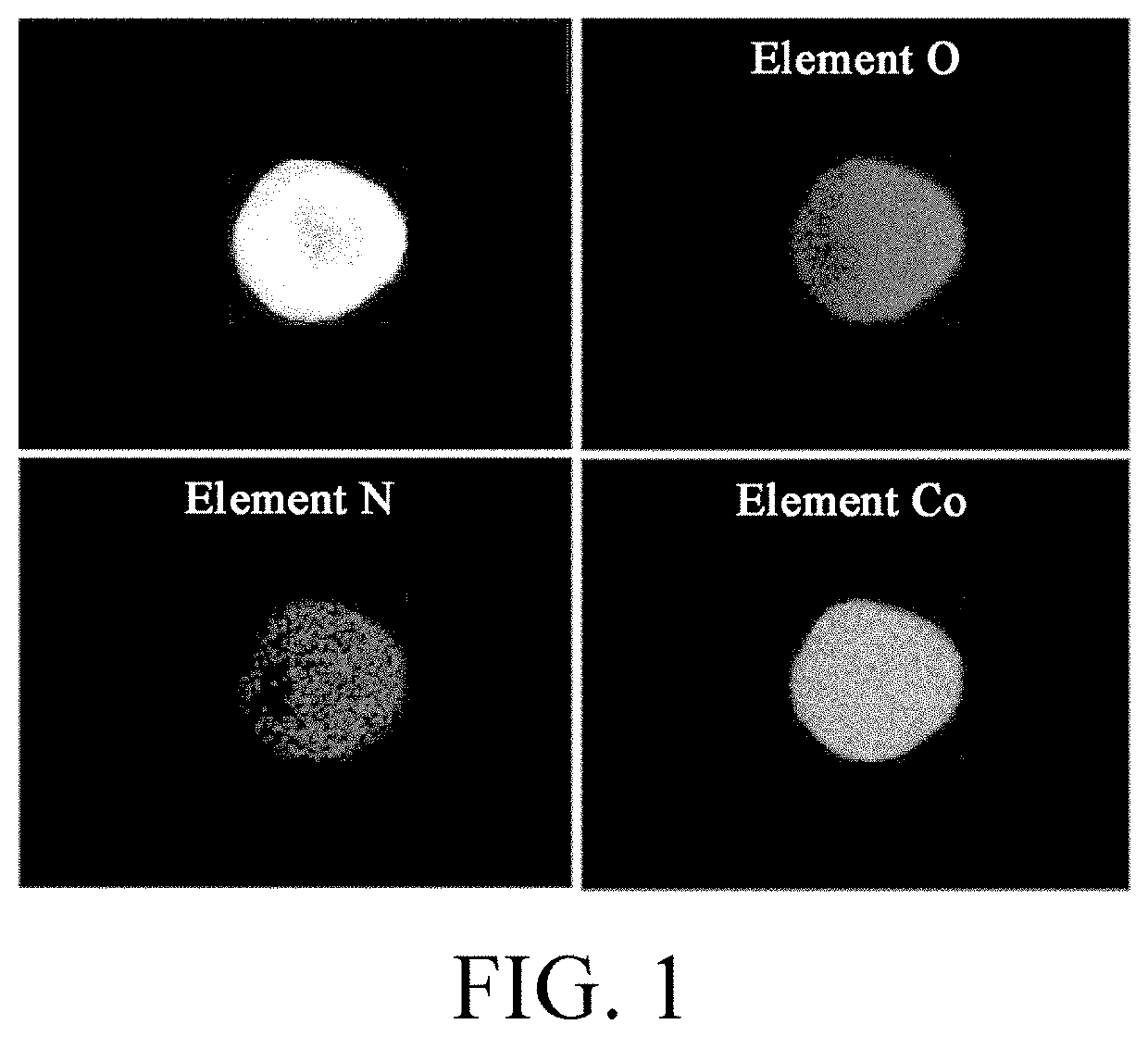

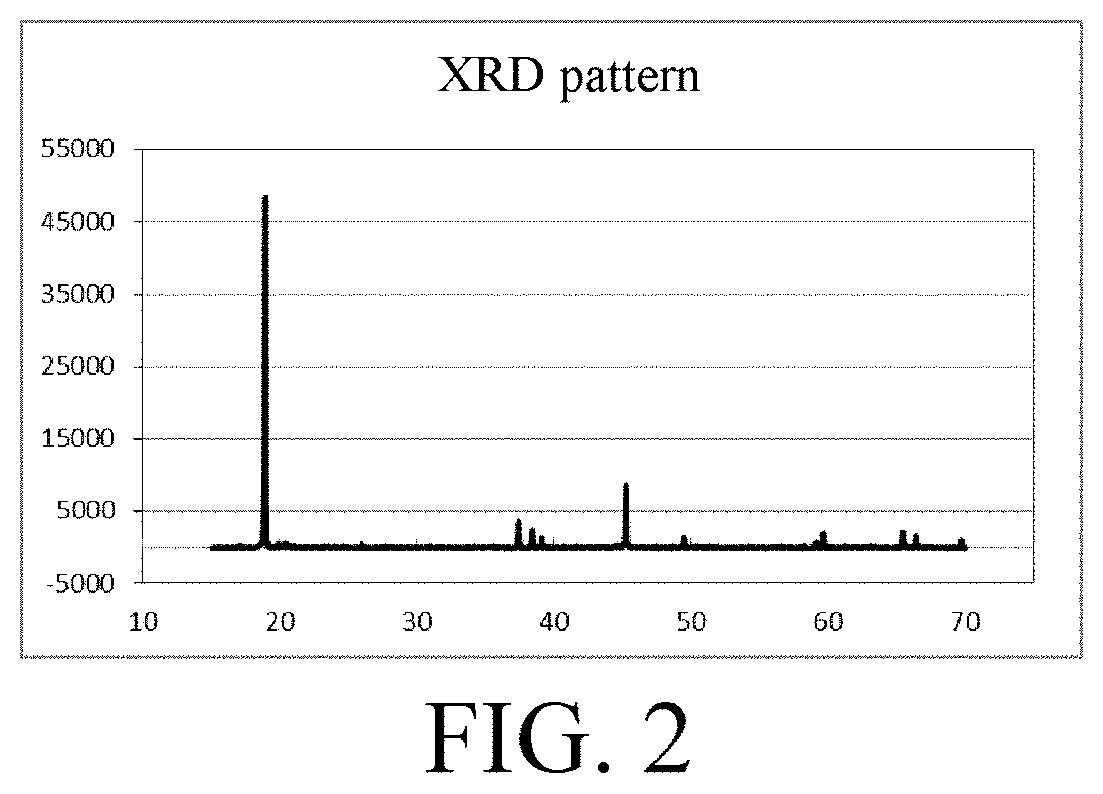

ActiveUS20190393501A1Achieve stabilityEasy to implementSecondary cellsPositive electrodesCharge dischargeHigh pressure

The present application relates to a metal oxide and synthesis of a lithium ion battery. Specifically, the present application selects a cobalt oxide compound, which uses Co3O4 as a main body, as a precursor of lithium cobalt oxide, and anion doping is performed in particles of Co3O4 to obtain a doped precursor for lithium cobalt oxide. The general formula of the precursor can be expressed as Co3(O1-yMy)4, where about 0<y<about 0.2, and wherein the anion M comprises at least one of F, P, S, Cl, N, As, Se, Br, Te, I or At. The lithium ion battery with a cathode made of lithium cobalt oxide material prepared by using the precursor presents good cycle stability in a high voltage charge-discharge environment.

Owner:NINGDE AMPEREX TECH

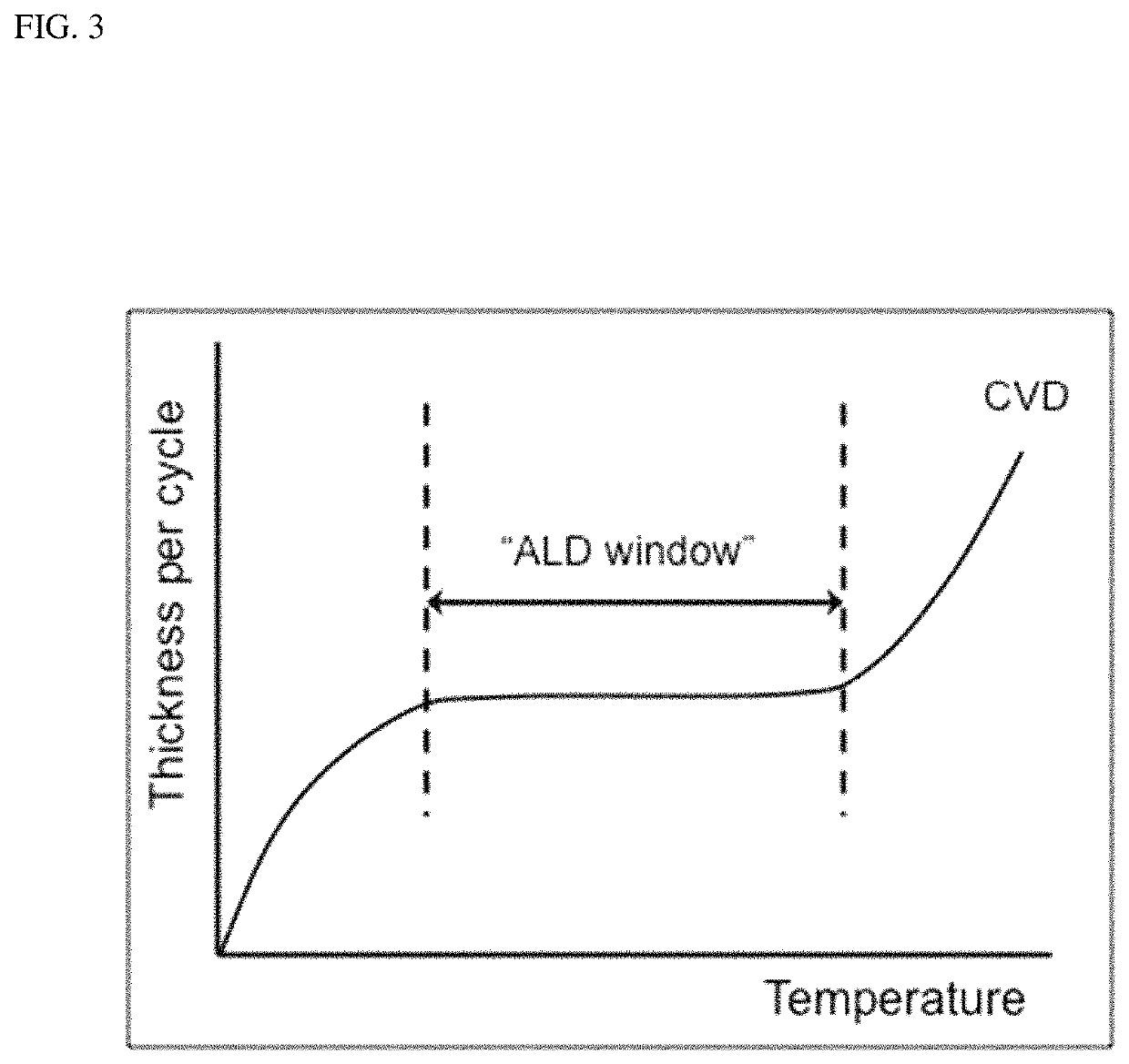

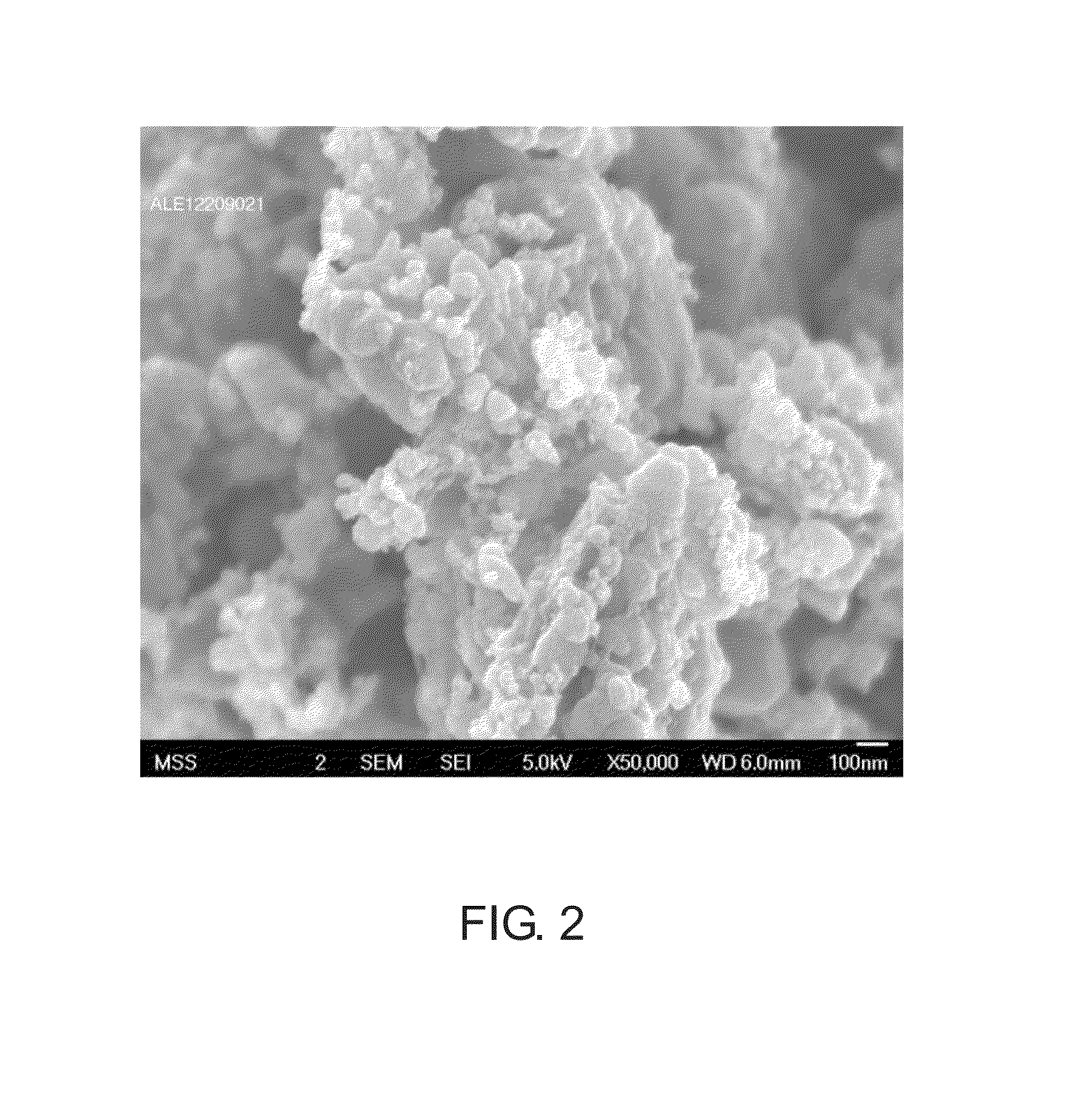

Dual conductor surface modified sofc cathode particles and methods of making same

ActiveUS20170170485A1Improve performanceSimplify the manufacturing processCell electrodesChemical vapor deposition coatingElectrical conductorFuel cells

A novel method to produce ALD films disposed on powders is disclosed. Examples include the formation of a cobalt doped zirconia (CDZ), hafnia, and cobalt doped hafnia (CDH) films on lanthanum strontium cobalt iron oxide (LSCF) powder for solid oxide fuel cell cathodes. The coated powders are sintered into porous cathodes that have utility for preventing the migration of cations in the powder to the surface of the sintered cathode and / or other performance enhancing attributes.

Owner:UNIVERSITY OF SOUTH CAROLINA +1

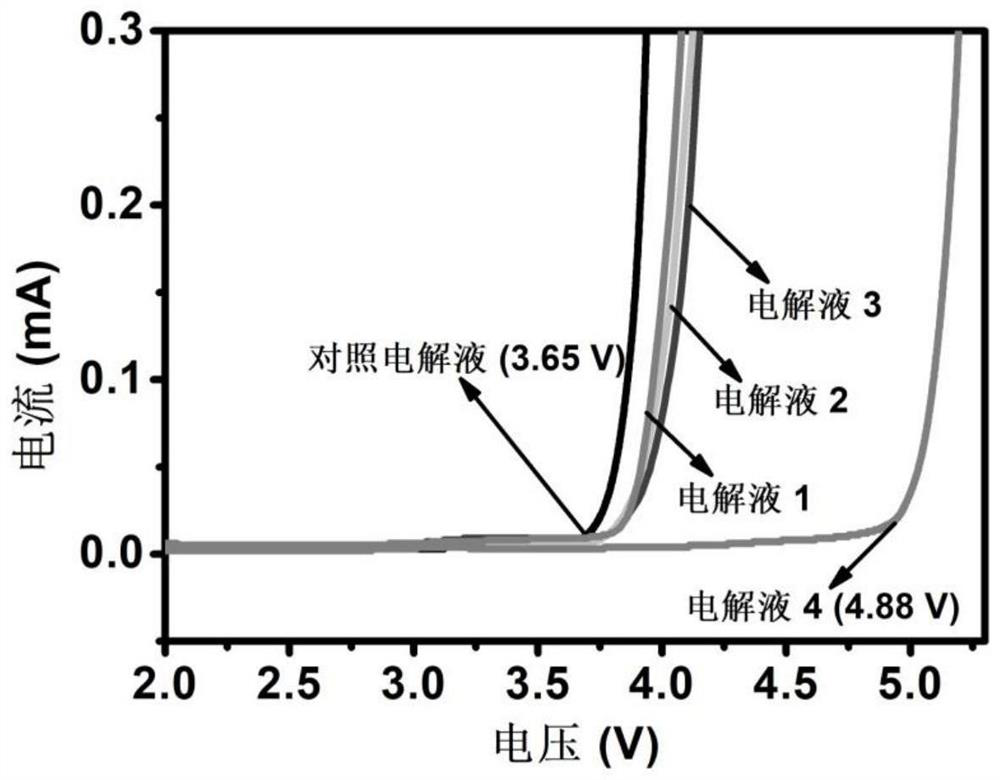

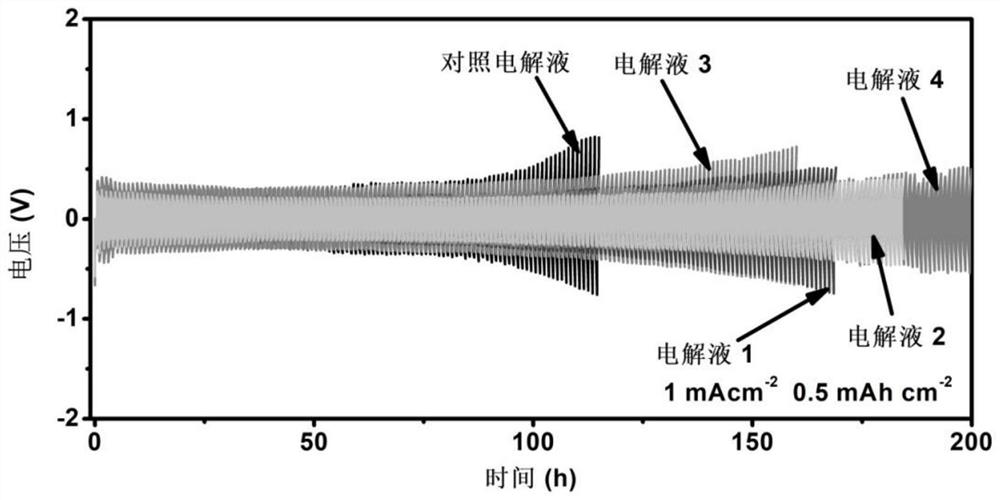

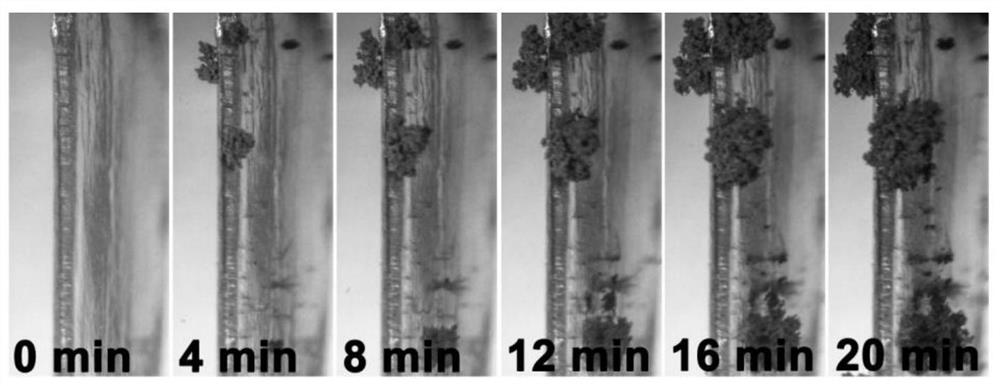

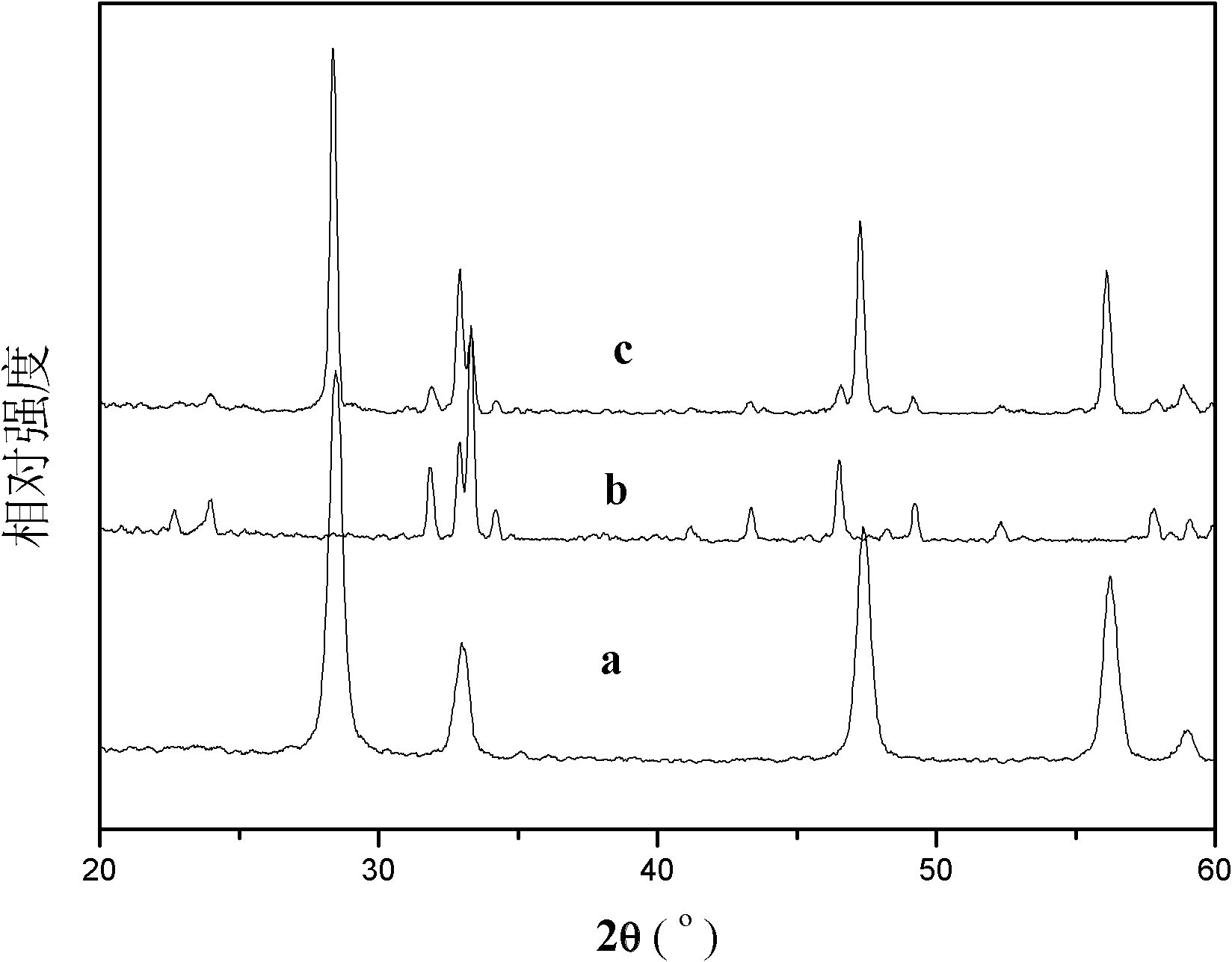

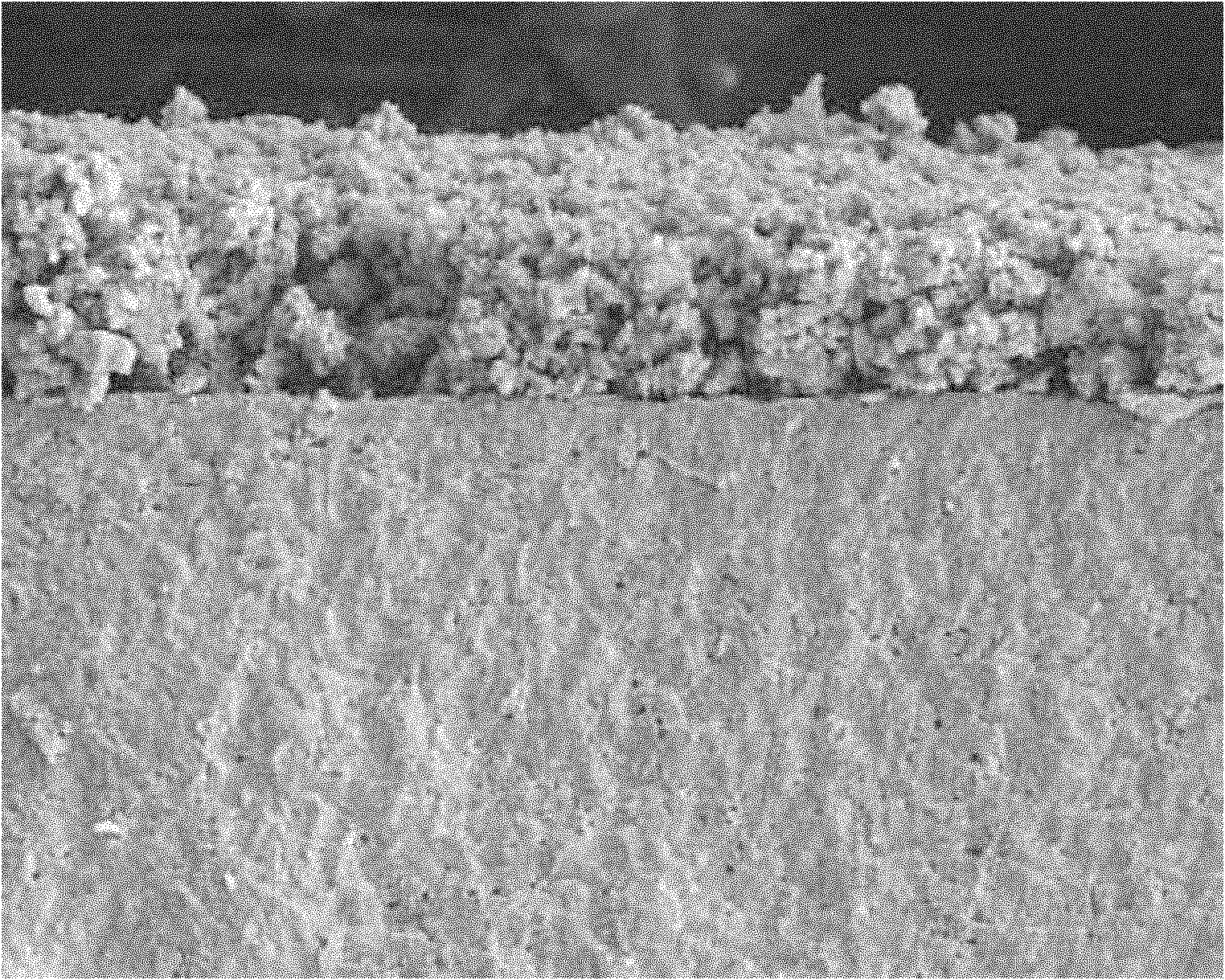

Electrolyte additive, electrolyte and sodium metal battery

ActiveCN113675470APriority restoreReduce decompositionSecondary cellsOrganic electrolytesElectrolytic agentBattery cell

In order to improve the oxidation resistance of an electrolyte, improve the overall coulombic efficiency of a battery, effectively inhibit the growth of sodium dendrites, improve the cycle stability of the battery and prolong the service life of the battery, the invention provides an electrolyte additive which comprises a benzene ring. The benzene ring has a first substituent group and a second substituent group; the first substituent group is fluorine; and the second substituent group is siloxane. Meanwhile, the invention also discloses an electrolyte containing the electrolyte additive and a sodium metal battery. According to the electrolyte provided by the invention, the oxidation resistance of the electrolyte is greatly improved, side reactions caused by oxygenolysis of the electrolyte in the discharge process are reduced, meanwhile, a negative electrode solid electrolyte membrane (SEI) and a positive electrode electrolyte interface membrane (CEI) of a sodium metal battery are optimized, the coulombic efficiency of the whole battery is improved, the growth of sodium dendrites is effectively inhibited, and the overall performance of the battery is improved.

Owner:HUNAN UNIV

Intermediate temperature solid oxide fuel battery composite cathode and preparation method thereof

InactiveCN101944617AIncreased mixed conductivityIncrease active areaCell electrodesDielectricComposite cathode

The invention discloses an intermediate temperature solid oxide fuel battery composite cathode and a preparation method thereof, and belongs to the field of chemical power solid oxide fuel battery materials. The invention solves the problem that the conventional cathode materials are not suitable for working under the condition of intermediate temperature. The composite cathode material is composed of Ca2Fe1.4Co0.6O5 and a solid dielectric which is Ce0.8Gd0.2O1.95 or Ce0.8Sm0.2O1.95. The method comprises the following steps of: 1, mixing the Ca2Fe1.4Co0.6O5 and the solid dielectric, adding terpilenol and uniformly mixing the three materials to obtain a mixed material; 2, coating the mixed material on the surface of the dielectric, and placing the dielectric in an oven for drying; and 3, sintering the dielectric to obtain the intermediate temperature solid oxide fuel battery composite cathode material on the surface of the dielectric. The cathode has the advantages of high electro-catalytic activity and low polarization resistance in the temperature range of 500 to 700 DEG C.

Owner:HEILONGJIANG UNIV

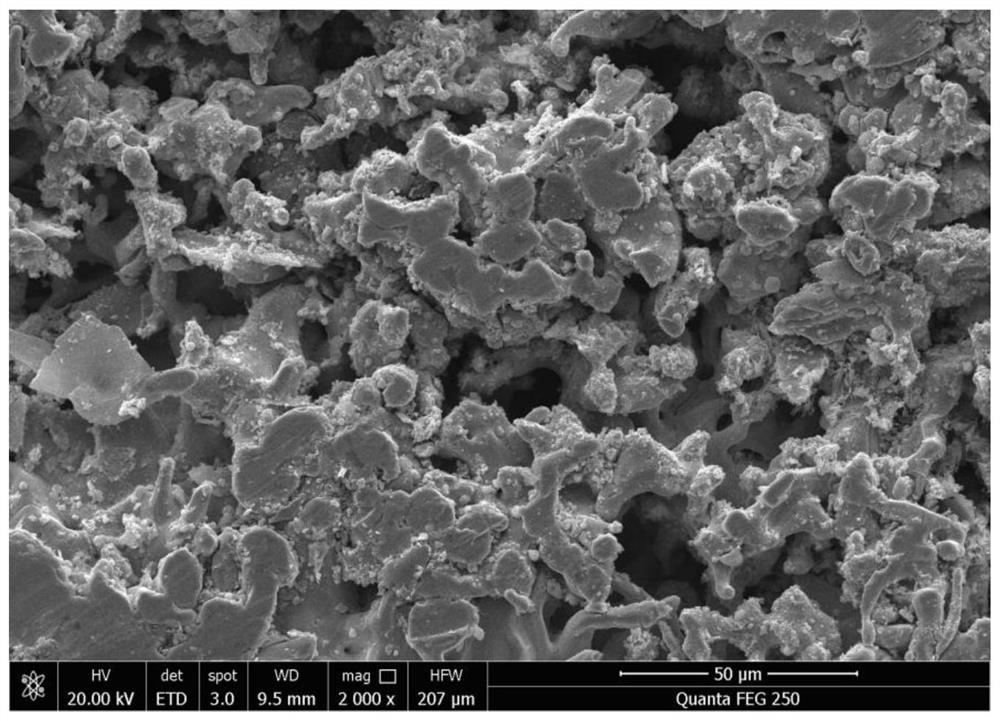

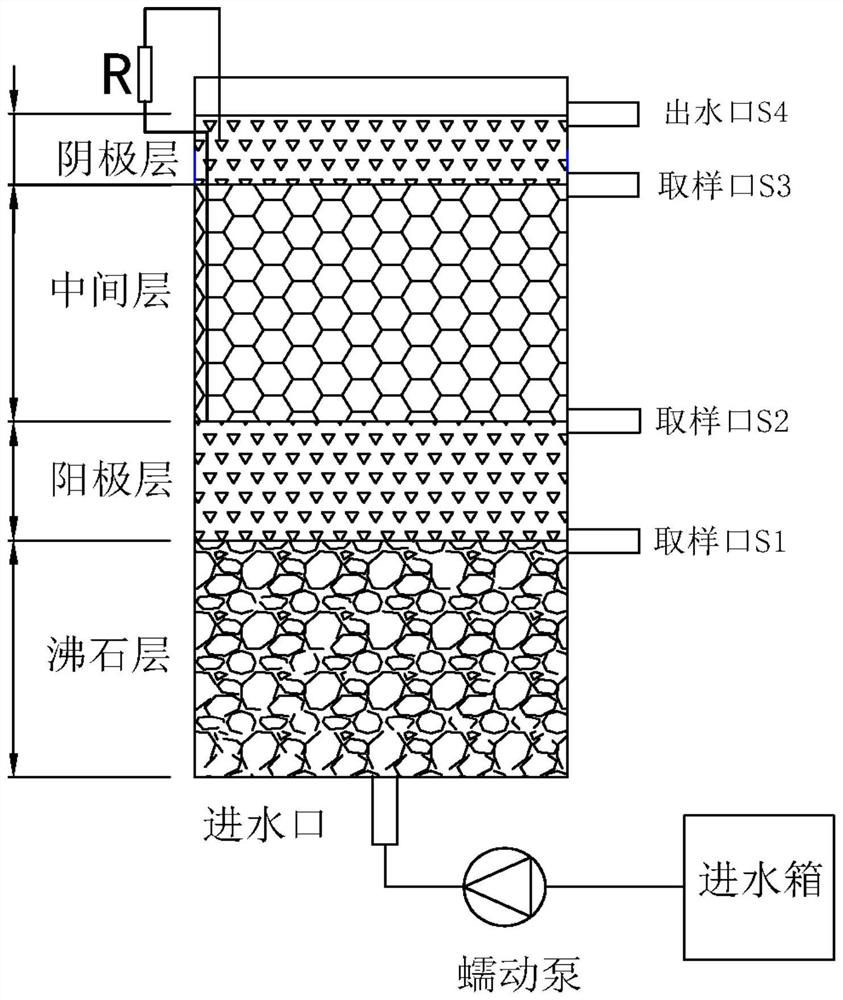

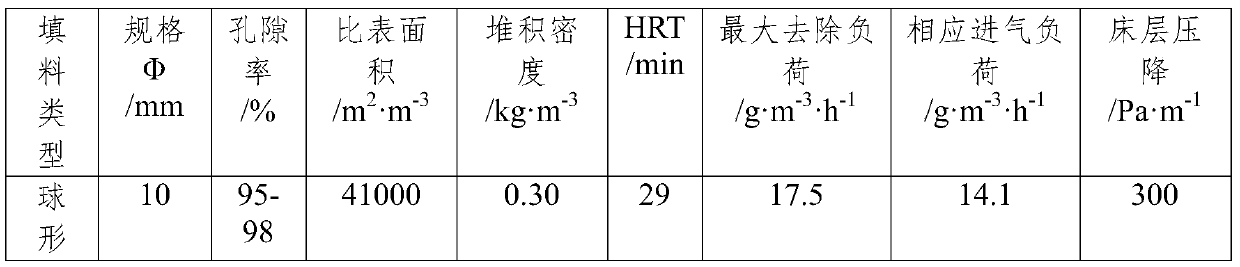

Foamed nickel and iron carbon combined biological filler and preparation method thereof

InactiveCN108996662ALarge biomassImprove conductivityTreatment by combined electrochemical biological processesTreatment with microorganism supports/carriersPolyesterStructural unit

The invention discloses a foamed nickel and iron carbon combined biological filler and a preparation method thereof. The foamed nickel and iron carbon combined biological filler includes foamed nickel, and iron carbon particles are wrapped in the foamed nickel; the foamed nickel has an ultrathin knitmesh flaky structure; an iron carbon particle matrix is cylindrical particles, and the outer surface of the matrix is covered with iron spicules fully. The preparation method of the foamed nickel and iron carbon combined biological filler comprises that the iron carbon particles are completely wrapped in the flaky foamed nickel, the product has a shape of sphere, and the foamed nickel is supported on the surface of the iron carbon particles by an iron needle-shaped net. The foamed nickel is prepared by an electrodeposition technology. The foamed nickel is a polyester polyurethane foamed plastic having pores opened by mechanical blasting, and the foamed plastic is composed of dodecahedral structural units with pentagonal windows. By adopting of the foamed nickel and iron carbon combined biological filler and the preparation method thereof, the energy consumption of the waste water and waste gas purification systems can be greatly reduced, the process treatment process does not involve secondary pollution, and the purification efficiency of degradation-resistant organic pollutants canbe fully improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

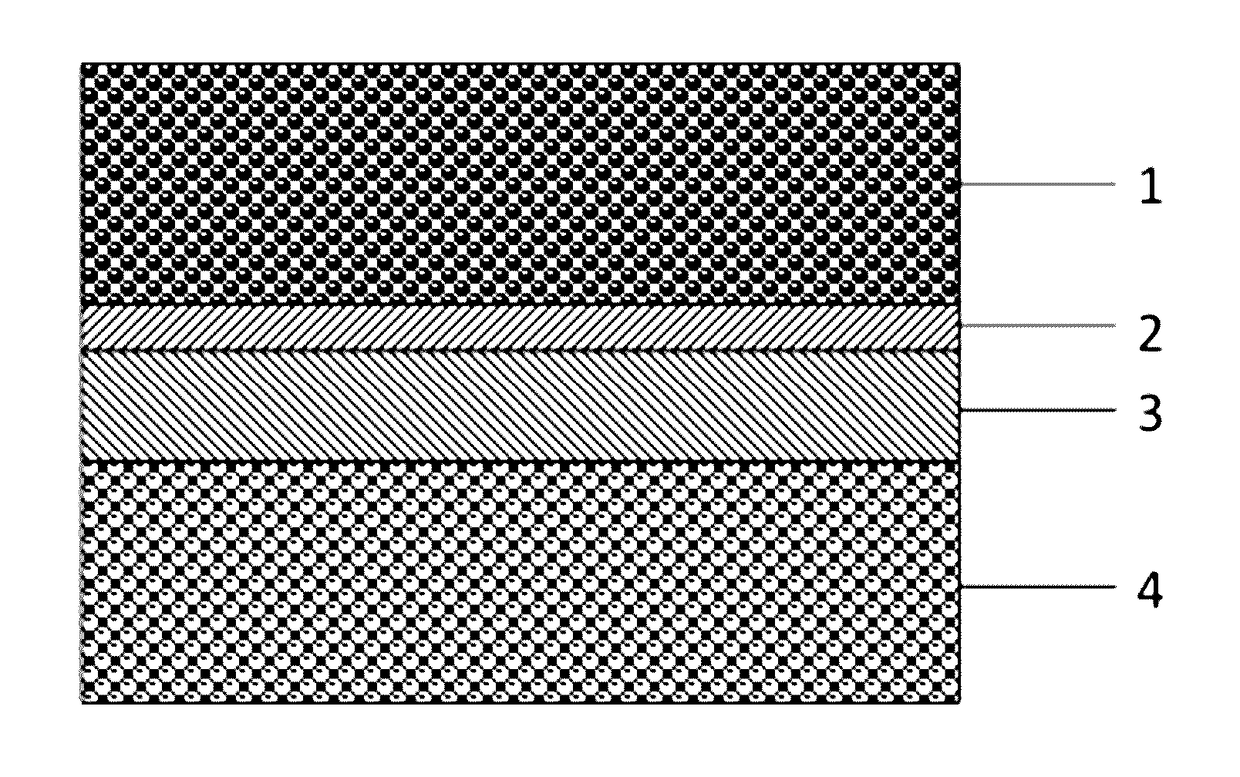

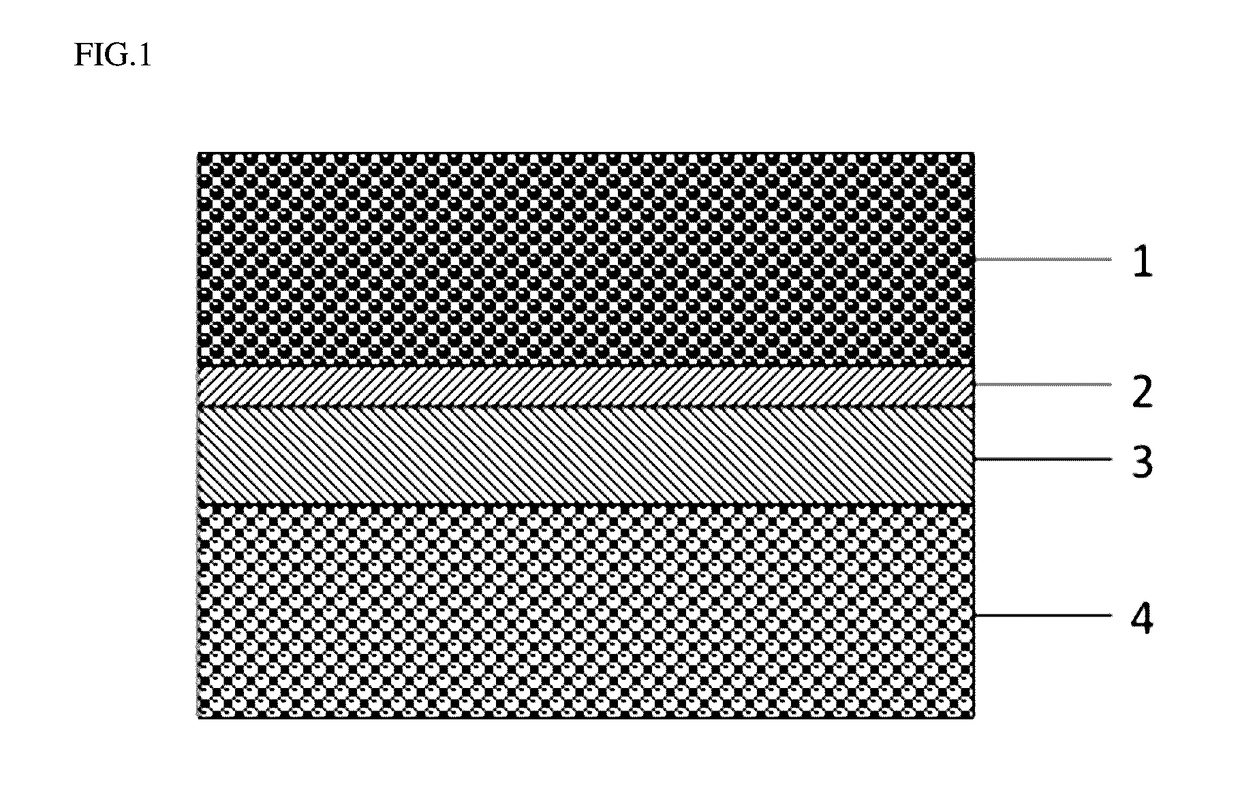

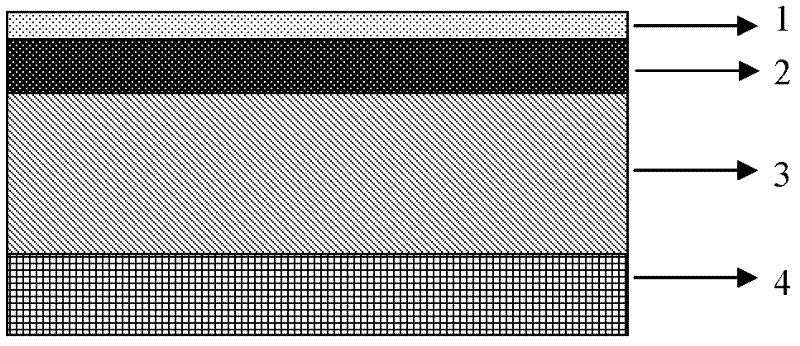

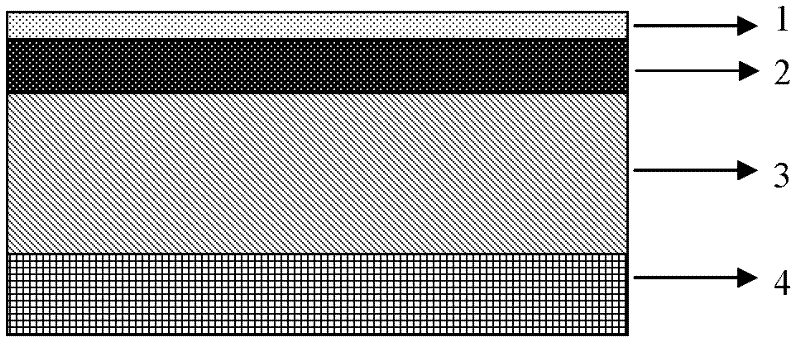

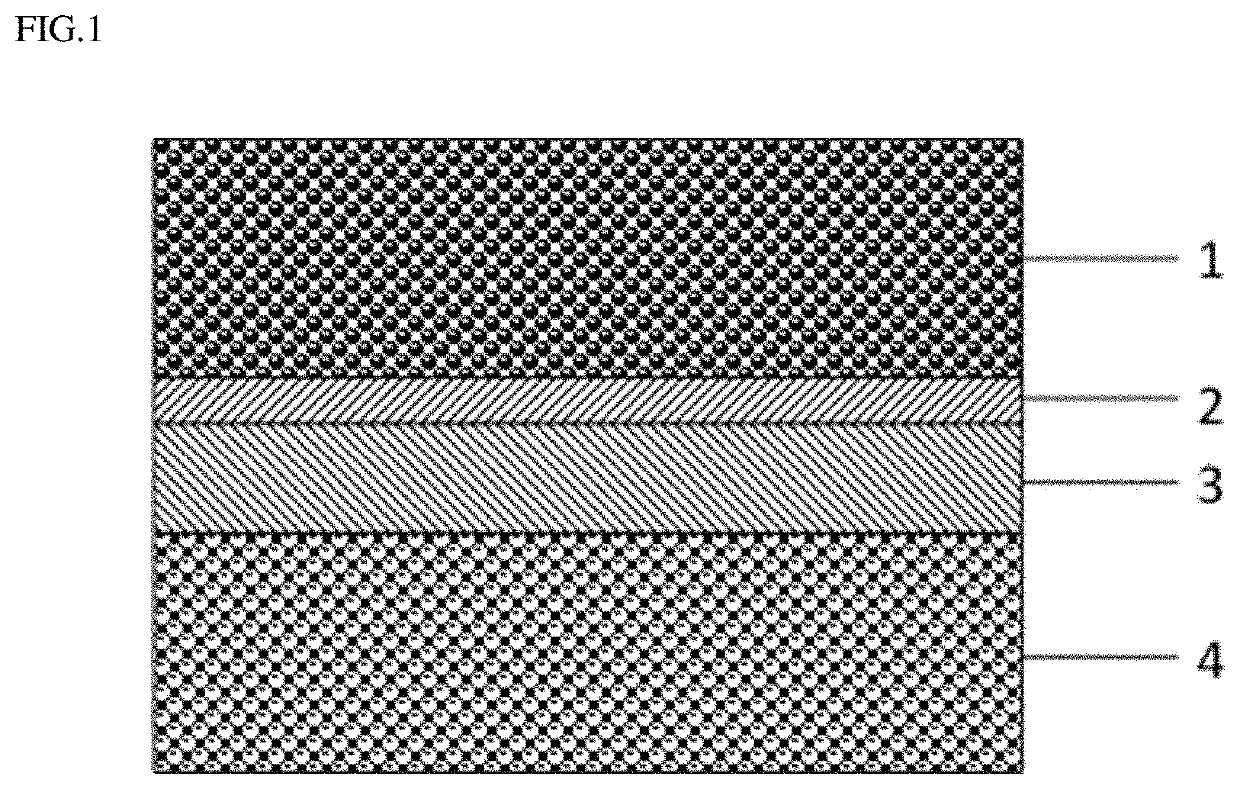

Solid oxide fuel cell structure and preparation method thereof

InactiveCN102347495AImprove adsorption capacityImproves the performance of dissociated oxygenCell electrodesSolid electrolyte fuel cellsSurface exchange coefficientFuel cells

The invention belongs to the field of solid oxide fuel cells, in particular relates to a solid oxide fuel cell structure and a preparation method thereof. The cell structure comprises a cell cathode layer, an electrolyte layer and a cell anode layer in sequence from top to bottom, wherein the cell cathode layer is divided into a PrBaCo2O5 layer and an LSM (La0.8S0.2MnO3) layer from top to bottom; the electrolyte layer is YSZ (Yttria Stabilized Zirconia); the cell anode layer is Ni-YSZ; and the thickness of the PrBaCo2O5 layer is 2-4 microns. Because PrBaCo2O5 has higher catalytic performance, oxygen diffusion coefficients, surface exchange coefficients and oxygen ion migration capability, the oxygen adsorbing capability and oxygen dissociating capability of a cathode can be improved by adopting a PrBaCo2O5-LSM / YSZ / Ni-YSZ structure and material system; and the solid oxide fuel cell structure has the characteristic of improving the cathode performance of the solid oxide fuel cells.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

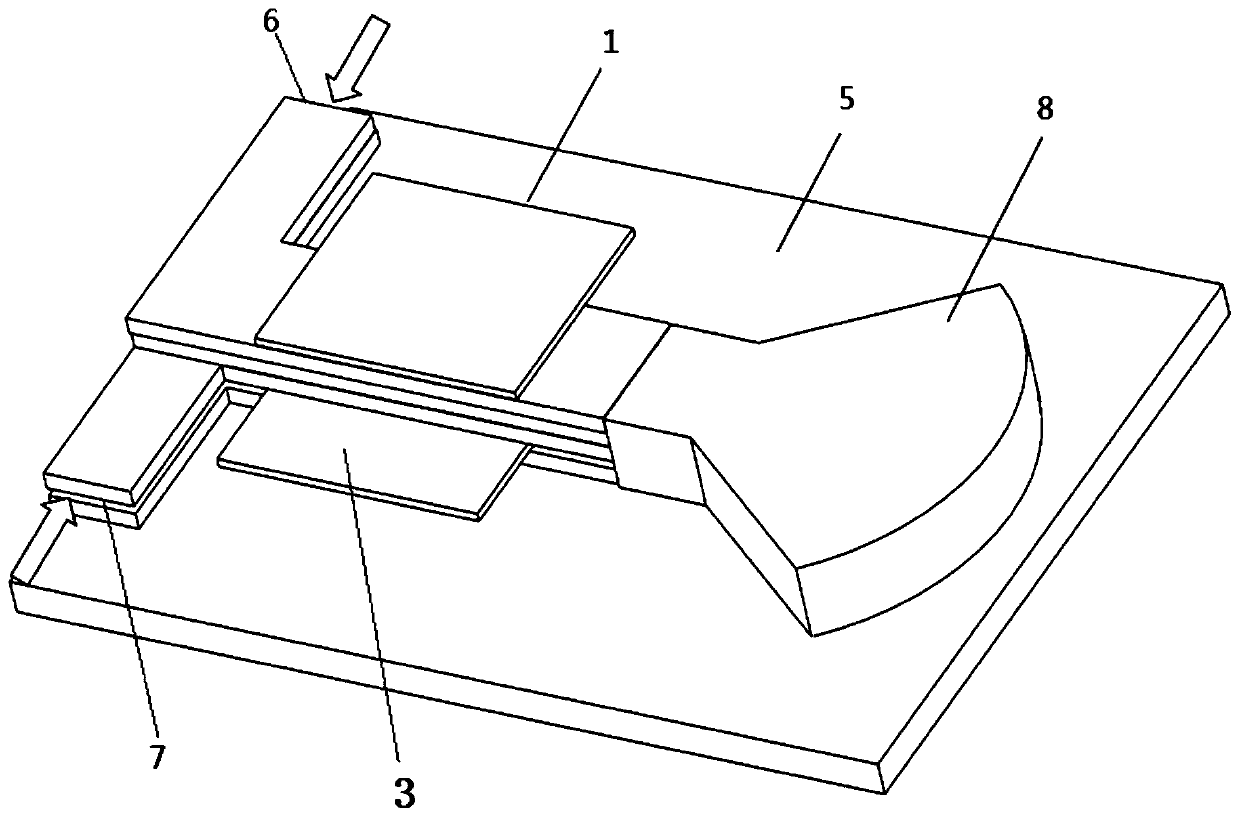

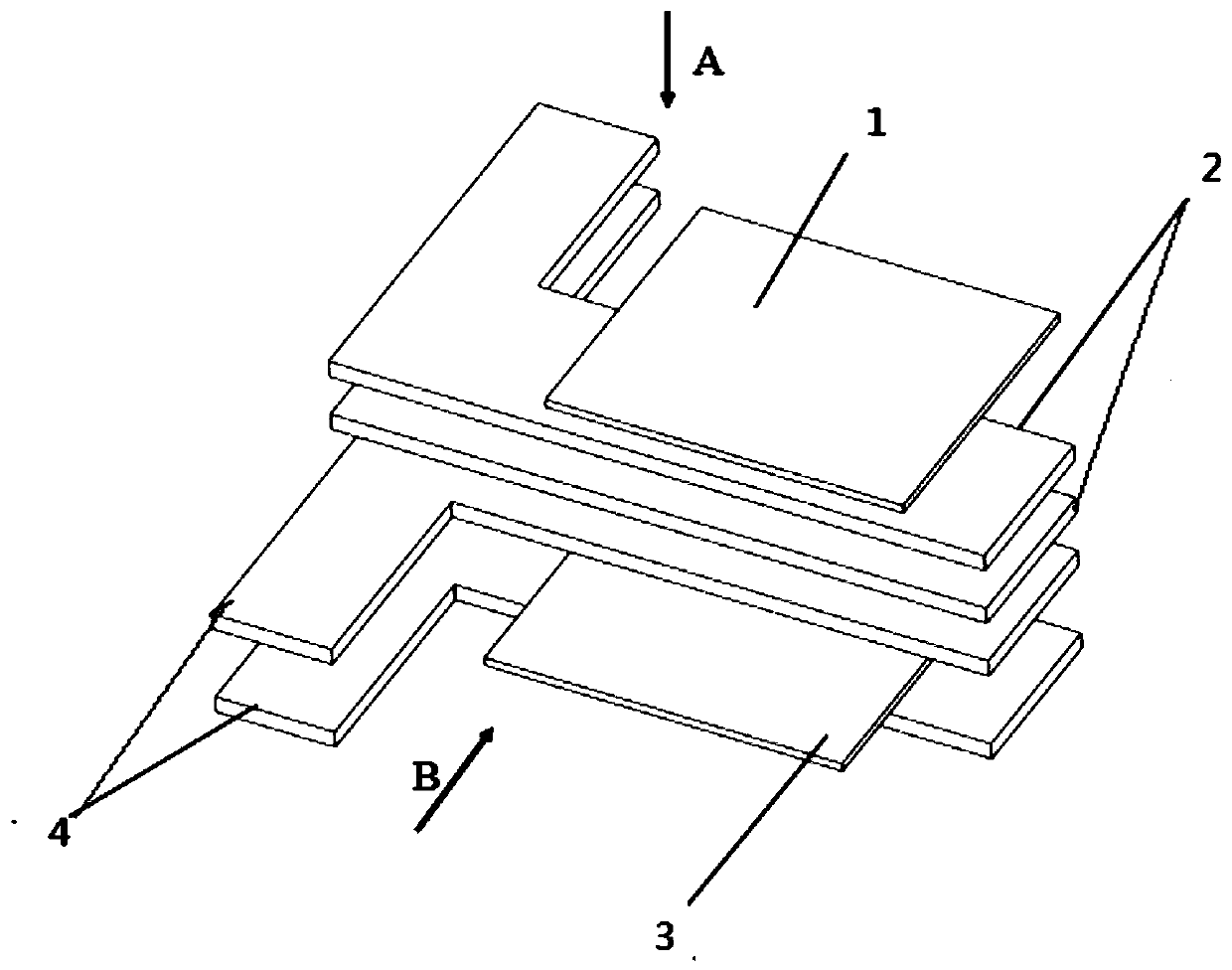

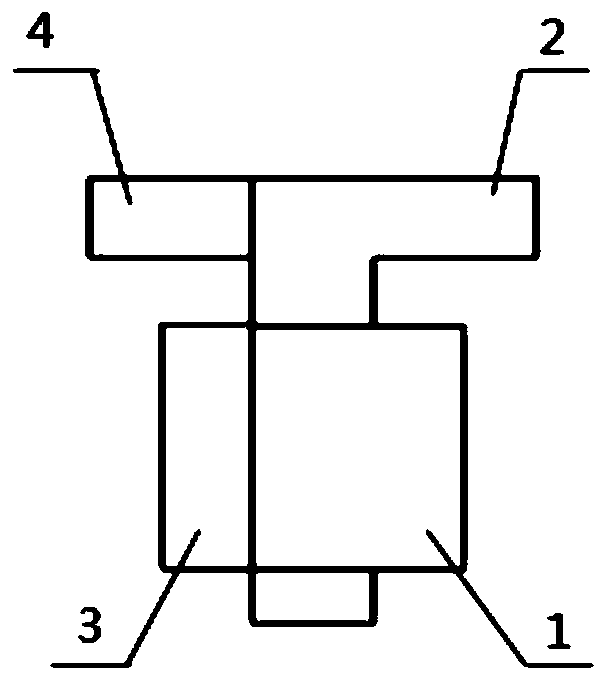

Stacked passive paper-based microfluidic fuel cell with opposite arrangement of cathode and anode

ActiveCN110534751AEnhanced cathode oxygen transportImprove cathode performanceCell electrodesFuel cellsBreathingEngineering

The invention discloses a stacked passive paper-based microfluidic fuel cell with opposite arrangement of cathode and anode. The stacked passive paper-based microfluidic fuel cell comprises an air self-breathing cathode, an electrolyte flow channel, a fuel flow channel, an anode and a bottom plate. The stacked passive paper-based microfluidic fuel cell is characterized in the electrolyte flow channel and the fuel flow channel are formed by stacking double-layer or multi-layer paper bases, and a certain gap is left among the paper bases as a flow channel for electrolyte or fuel. The electrolyteflow channel is located above the fuel flow channel. The air self-breathing cathode and the anode are arranged opposite in a vertical direction, and the air self-breathing cathode is arranged above and in contact with the electrolyte flow channel. The air self-breathing cathode is composed of a hydrophobic porous electrode, and a catalytic layer is arranged at the contact part with the electrolyte flow channel. The anode is embedded in the fuel flow channel in a horizontal direction and forms a wedge-shaped gap with the fuel flow channel. The anode is composed of a hydrophilic electrode, anda catalytic layer is arranged at the part overlapping the fuel flow channel. The stacked passive paper-based microfluidic fuel cell can be widely applied in the fields of power supply and the like.

Owner:CHONGQING UNIV

Method for producing cathode active material and method for manufacturing nonaqueous electrolyte cell

InactiveCN1350339AImprove cathode performanceImprove performanceElectrode manufacturing processesNon-aqueous electrolyte accumulatorsManganeseLithium manganese oxide

A method for producing a cathode active material which produces a spinel type lithium manganese oxide expressed by a general formula: Li1+xMn2-x-yMeyPO4, as the cathode active material, (here, x is expressed by a relation of 0<=x<=0.15 and y is expressed by a relation of 0 C01D 15 / 02 H01M 4 / 04 1 19 31 2001 / 10 / 23 1350339 2002 / 5 / 22 1189959 2005 / 2 / 16 2005 / 2 / 16 2005 / 2 / 16 Sony Corp. Japan Sakai Hideki Fukuba Shigeshi Takahashi Kimio wang jie 11038 The Patent Agency of the Chinese Council for the Promotion of International Trade (CCPIT) No.1 Waidajie, Fuxingmen, Beijing 100086 Japan 2000 / 10 / 23 323214 / 2000

Owner:SONY CORP

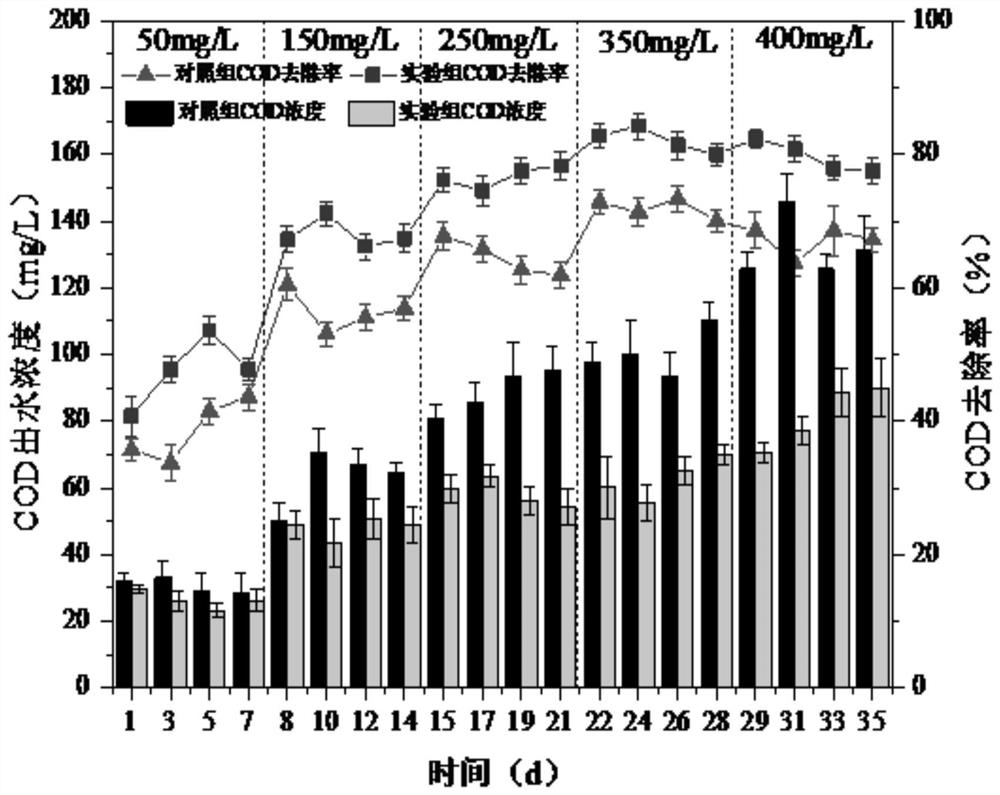

Iron-carbon micro-electrolysis filler as well as preparation method and application thereof

InactiveCN112551679ALarge specific surface areaImprove surface activityTreatment by combined electrochemical biological processesWater contaminantsElectrolysisNew energy

The invention provides an iron-carbon micro-electrolysis filler as well as a preparation method and application thereof, and belongs to the technical field of new energy and environmental engineering.The method comprises the following steps: firstly, preparing an iron-carbon micro-electrolysis filler, and then constructing a CW-MFC system by taking the iron-carbon micro-electrolysis filler as a matrix of a coupling system. The system has the dual functions of sewage treatment and biological power generation, chemical energy is recycled in the form of electric energy while sewage is treated, and the win-win situation of environment-friendly ecological improvement and energy conservation is achieved.

Owner:GUOHE ENVIRONMENTAL RES INST (NANJING) CO LTD

Metal oxide and synthesis of lithium ion battery

ActiveUS10944106B2Improve material stabilityImprove cathode performanceSecondary cellsPositive electrodesElectrical batteryHigh voltage

The present application relates to a metal oxide and synthesis of a lithium ion battery. Specifically, the present application selects a cobalt oxide compound, which uses Co3O4 as a main body, as a precursor of lithium cobalt oxide, and anion doping is performed in particles of Co3O4 to obtain a doped precursor for lithium cobalt oxide. The general formula of the precursor can be expressed as Co3(O1-yMy)4, where about 0<y<about 0.2, and wherein the anion M comprises at least one of F, P, S, Cl, N, As, Se, Br, Te, I or At. The lithium ion battery with a cathode made of lithium cobalt oxide material prepared by using the precursor presents good cycle stability in a high voltage charge-discharge environment.

Owner:NINGDE AMPEREX TECH

Foamed nickel and iron carbon combination type biological filler and preparation method thereof

ActiveCN109748380ALarge biomassImprove conductivityTreatment by combined electrochemical biological processesTreatment with microorganism supports/carriersPolyesterPersistent organic pollutant

The invention discloses a foamed nickel and iron carbon combination type biological filler and a preparation method thereof. The foamed nickel and iron carbon combination type biological filler comprises foamed nickle; the foamed nickle is internally coated with iron carbon particles; the foamed nickle adopts an ultrathin netting type sheet structure; and the matrix of the iron carbon particles adopts cylindrical particles, the outer surfaces of the cylindrical particles are distributed with acicular ferrite. According to the preparation method of the foamed nickel and iron carbon combinationtype biological filler, the iron carbon particles are completely coated with the sheet-shaped foamed nickle, and the shape is spherical, and the foamed nickle is supported on the surfaces of the ironcarbon particles through an acicular ferrite net; wherein the foamed nickle is prepared by adopting an electrodeposition technology; the foamed nickle adopts polyester-type polyurethane polyfoam withholes formed by mechanical blasting; and the polyfoam is composed of a dodecahedral structural element with a pentagonal window. By adopting the preparation method provided by the invention, the energy consumption of a purification system of waste water and waste gas is greatly reduced, no secondary pollution is involved during the process treatment, and the efficiency in purifying persistent organic pollutants is fully improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Solid oxide fuel cell structure and preparation method thereof

InactiveCN102347495BImprove adsorption capacityImprove cathode performanceCell electrodesSolid electrolyte fuel cellsSurface exchange coefficientFuel cells

The invention belongs to the field of solid oxide fuel cells, in particular relates to a solid oxide fuel cell structure and a preparation method thereof. The cell structure comprises a cell cathode layer, an electrolyte layer and a cell anode layer in sequence from top to bottom, wherein the cell cathode layer is divided into a PrBaCo2O5 layer and an LSM (La0.8S0.2MnO3) layer from top to bottom; the electrolyte layer is YSZ (Yttria Stabilized Zirconia); the cell anode layer is Ni-YSZ; and the thickness of the PrBaCo2O5 layer is 2-4 microns. Because PrBaCo2O5 has higher catalytic performance, oxygen diffusion coefficients, surface exchange coefficients and oxygen ion migration capability, the oxygen adsorbing capability and oxygen dissociating capability of a cathode can be improved by adopting a PrBaCo2O5-LSM / YSZ / Ni-YSZ structure and material system; and the solid oxide fuel cell structure has the characteristic of improving the cathode performance of the solid oxide fuel cells.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

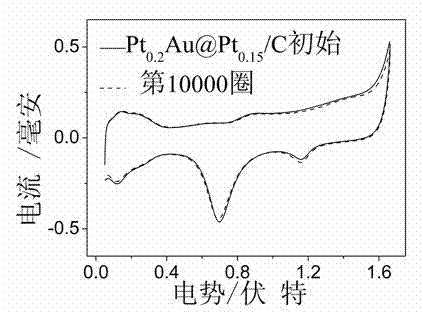

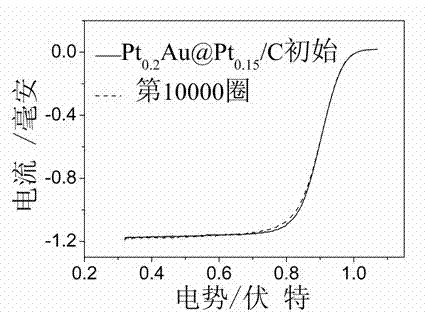

Pt-Au@Pt core-shell structure fuel cell cathode catalyst and preparation method thereof

InactiveCN103084175BSolve resource problemsAbundant resourcesCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFuel cellsCore shell

The invention discloses a Pt-Au@Pt core-shell structure fuel cell cathode catalyst and a preparation method thereof. The Pt-Au@Pt core-shell structure fuel cell cathode catalyst consists of a conductive carrier and Pt-Au@Pt core-shell structure nanoparticles. The preparation method comprises the following steps of: reducing a gold compound by using sodium borohydride to obtain Au nanoparticles, and loading the Au particles on the surface of a carbon carrier to obtain Au / C; and putting Au / C in a platinum compound water solution to obtain loaded-type Pt / Au alloy nanoparticles after Pt is subjected to spontaneous reductive deposition on the Au surface, depositing a Cu atom monolayer on the surface of the Pt-Au alloy nanoparticles by using an underpotential deposition method and then displacing the Cu atom monolayer with Pt to obtain the Pt-Au@Pt core-shell structure fuel cell cathode catalyst. The catalyst prepared by using the preparation method disclosed by the invention is high in catalytic activity and stability and low in cost relative to a pure Pt catalyst; and the preparation method is simple and convenient, mild in condition and easy to operate and can be used for solving the problem that a core-shell structure catalyst prepared by using a conventional chemical reduction method is high in Pt agglomeration degree on the surface and a catalyst prepared by using a single underpotential deposition method is low in Pt coverage degree on the surface.

Owner:WUHAN UNIV

Dual conductor surface modified SOFC cathode particles and methods of making same

ActiveUS10741850B2Promote migrationImprove performance and long-term reliabilityCell electrodesChemical vapor deposition coatingFuel cellsElectrical conductor

A novel method to produce ALD films disposed on powders is disclosed. Examples include the formation of a cobalt doped zirconia (CDZ), hafnia, and cobalt doped hafnia (CDH) films on lanthanum strontium cobalt iron oxide (LSCF) powder for solid oxide fuel cell cathodes. The coated powders are sintered into porous cathodes that have utility for preventing the migration of cations in the powder to the surface of the sintered cathode and / or other performance enhancing attributes.

Owner:UNIVERSITY OF SOUTH CAROLINA +1

Intermediate temperature solid oxide fuel battery composite cathode and preparation method thereof

InactiveCN101944617BIncreased mixed conductivityIncrease active areaCell electrodesDielectricComposite cathode

The invention discloses an intermediate temperature solid oxide fuel battery composite cathode and a preparation method thereof, and belongs to the field of chemical power solid oxide fuel battery materials. The invention solves the problem that the conventional cathode materials are not suitable for working under the condition of intermediate temperature. The composite cathode material is composed of Ca2Fe1.4Co0.6O5 and a solid dielectric which is Ce0.8Gd0.2O1.95 or Ce0.8Sm0.2O1.95. The method comprises the following steps of: 1, mixing the Ca2Fe1.4Co0.6O5 and the solid dielectric, adding terpilenol and uniformly mixing the three materials to obtain a mixed material; 2, coating the mixed material on the surface of the dielectric, and placing the dielectric in an oven for drying; and 3, sintering the dielectric to obtain the intermediate temperature solid oxide fuel battery composite cathode material on the surface of the dielectric. The cathode has the advantages of high electro-catalytic activity and low polarization resistance in the temperature range of 500 to 700 DEG C.

Owner:HEILONGJIANG UNIV

A kind of preparation method of composite cathode material for fuel cell

ActiveCN111146456BIncrease the reaction areaImprove cathode performanceMaterial nanotechnologyCell electrodesComposite cathodeFuel cells

The invention discloses a method for preparing a composite cathode material for a fuel cell, and belongs to the technical field of fuel cell electrode material preparation. It is through Gd z Ce 1‑z o 2 (z is 0~1) Composite enhanced La x Sr 1‑x co y Fe 1‑y o 3‑δ (x is 0~1, y is 0~1) performance. The cathode particle obtained by the invention has a greater improvement on the original structure and can exhibit significantly high catalytic activity. The preparation material of the invention is simple and easy to obtain, the process is stable, and the requirements of industrial production can be met.

Owner:FUZHOU UNIV

Cathode material with oxygen vacancy and manufacturing process thereof

ActiveUS20150021517A1Improve cathode performanceIncrease capacityPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphateLithium metal

Owner:ADVANCED LITHIUM ELECTROCHEMISTRY CO LTD

Lithium battery cathode

ActiveUS20180248184A1Fast productionIncrease speedElectrode thermal treatmentPositive electrodesEngineeringLithium-ion battery

A novel lithium battery cathode, a lithium ion battery using the same and processes and preparation thereof are disclosed. The battery cathode is formed by force spinning. Fiber spinning allows for the formation of core-shell materials using material chemistries that would be incompatible with prior spinning techniques. A fiber spinning apparatus for forming a coated fiber and a method of forming a coated fiber are also disclosed.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com