Composite oxide carbon carrier-loaded nano Pt catalyst and preparation method and application thereof

A composite oxide, carbon support technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor hydrophilicity, weak metal support, poor catalytic activity and stability , to achieve the effect of good catalytic activity, improved quality activity, improved catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

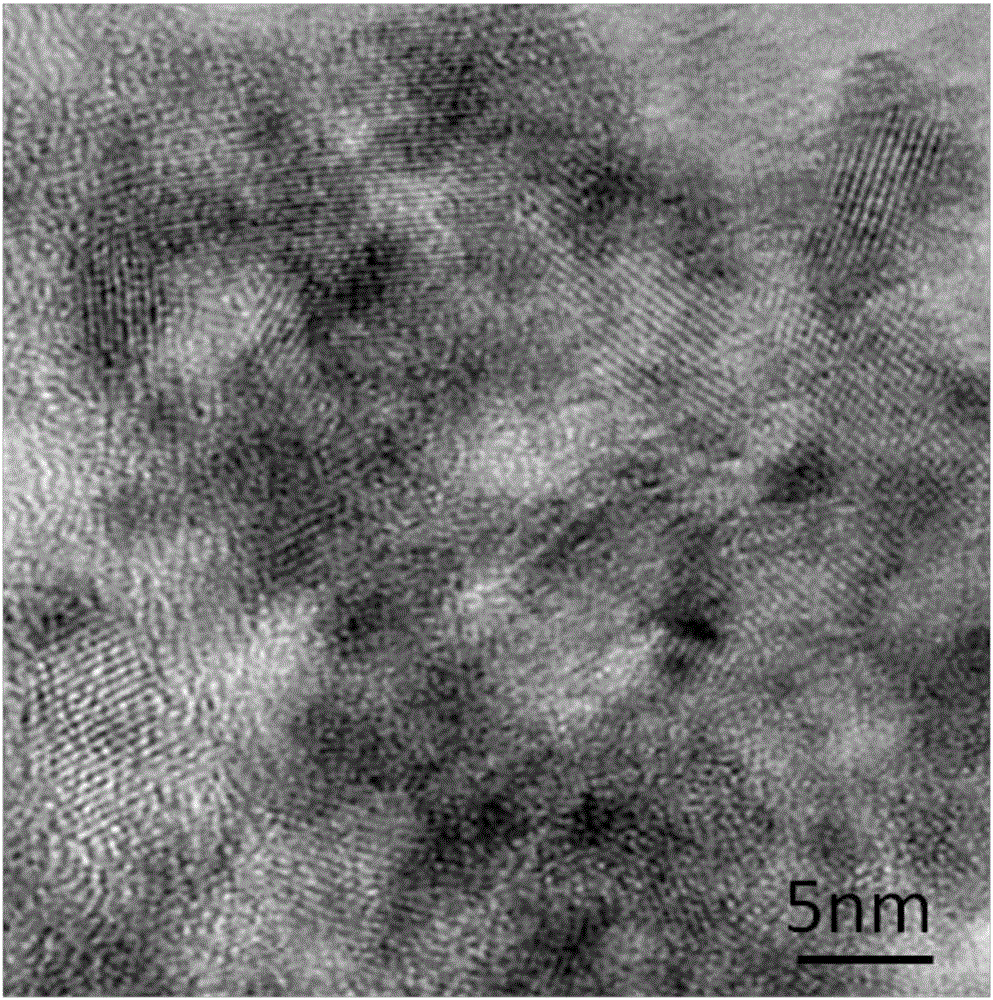

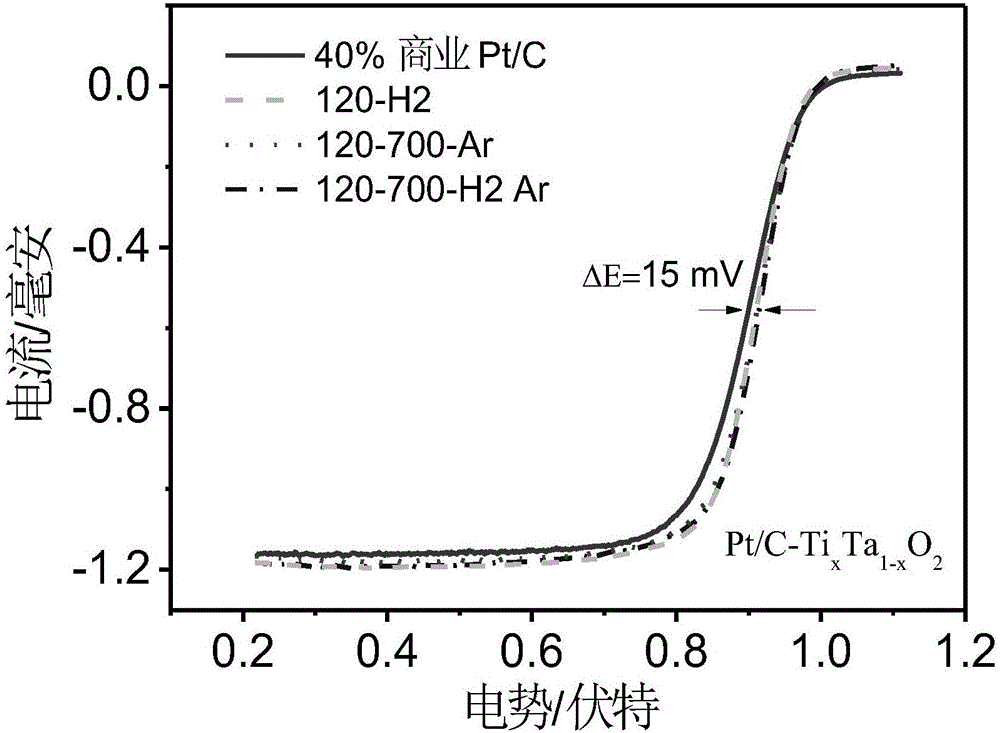

[0048] (1)Pt / C-Ti x Ta 1-x o 2 Catalyst (Pt / C-Ti x Ta 1-x o 2 -120℃-H 2 , x=0.7) Preparation:

[0049] In the method of hydrothermal synthesis, 22.95 μL TiCl 4 and 32.235 mg TaCl 5 Add water, and add 100mg of conductive carbon black EC-300 (Shanghai Hesen) as a high specific surface carbon carrier, and stir it ultrasonically for 30 minutes to make it evenly mixed; React in the furnace for 2h, then cool to room temperature, centrifuge, wash with ultrapure water for several times, dry, and then calcinate in Ar at 500°C for 3h, and finally get the composite oxide carbon support C-Ti x Ta 1-x o 2 ; The C-Ti obtained in the previous step x Ta 1-x o 2 Ultrasonic dispersion in 445μL chloroplatinic acid aqueous solution (75mg pt / mL), soaked for 3 hours to obtain H 2 PtCl 6 / C-Ti x Ta 1-x o 2 , after freeze-drying, put H in a tube furnace at 120 °C 2 Reduction for 1h to obtain the catalyst Pt / C-Ti x Ta 1-x o 2 -120℃-H 2 , the resulting catalyst Pt / C-Ti x Ta 1...

Embodiment 2

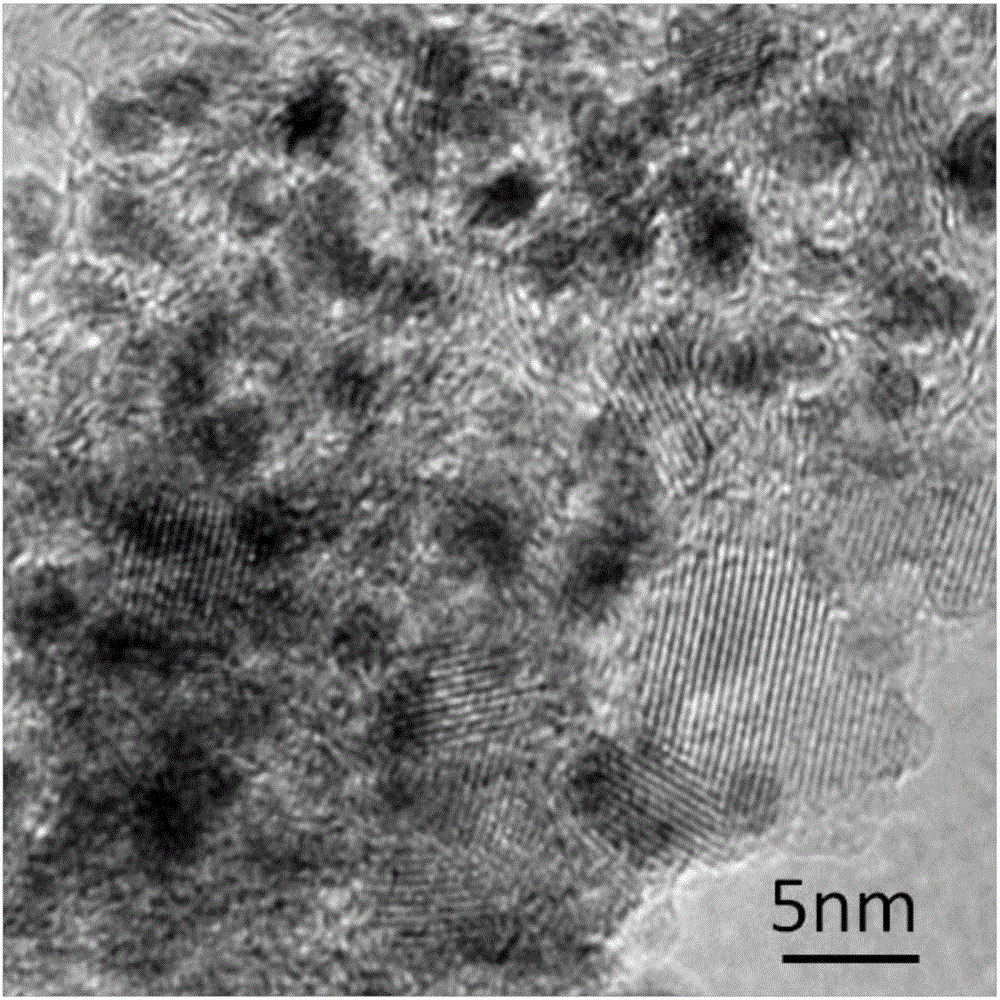

[0056] (1)Pt / C-Ti x Ta 1-x o 2 Catalyst (Pt / C-Ti x Ta 1-x o 2 -120℃-H 2 -700°C-Ar, x=0.7) Preparation:

[0057] In the method of hydrothermal synthesis, 22.95 μL TiCl 4 and 32.235 mg TaCl 5 Add water, and add 100mg of conductive carbon black EC-300 (Shanghai Hesen) as a high specific surface carbon carrier, and stir it ultrasonically for 30 minutes to make it evenly mixed; React in the furnace for 2h, then cool to room temperature, centrifuge, wash with ultrapure water for several times, dry, and then calcinate in Ar at 500°C for 3h, and finally get the composite oxide carbon support C-Ti x Ta 1-x o2 ; The composite oxide carbon carrier C-Ti prepared in the previous step x Ta 1-x o 2 Ultrasonic dispersion in 445μL chloroplatinic acid aqueous solution (75mg pt / mL), soaked for 3 hours to obtain H 2 PtCl 6 / C-Ti x Ta 1-x o 2 , which was lyophilized and passed through H in a tube furnace at 120 °C 2 Reduction 1h, followed by H 2 Replace it with Ar, and further...

Embodiment 3

[0065] (1)Pt / C-Ti x Ta 1-x o 2 Catalyst (Pt / C-Ti x Ta 1-x o 2 -120℃-H 2 -700℃-H 2 / Ar, x=0.7) preparation:

[0066] In the method of hydrothermal synthesis, 22.95 μL TiCl 4 and 32.235 mg TaCl 5 Add water, and add 100mg of conductive carbon black EC-300 (Shanghai Hesen) as a high specific surface carbon carrier, and stir it ultrasonically for 30 minutes to make it evenly mixed; React in the furnace for 2h, then cool to room temperature, centrifuge, wash with ultrapure water for several times, dry, and then calcinate in Ar at 500°C for 3h, and finally get the composite oxide carbon support C-Ti x Ta 1-x o 2 ; The composite oxide carbon carrier C-Ti prepared in the previous step x Ta 1-x o 2 Ultrasonic dispersion in 445μL chloroplatinic acid aqueous solution (75mg pt / mL), soaked for 3 hours to obtain H 2 PtCl 6 / C-Ti x Ta 1-x o 2 , after freeze-drying, H was introduced into a tube furnace at 120 °C 2 Reduction 1h, followed by H 2 Change to H 2 / Ar (v / v, 5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com