Method for producing cathode active material and method for manufacturing nonaqueous electrolyte cell

A cathode active material, non-aqueous electrolyte technology, applied in non-aqueous electrolyte batteries, electrode manufacturing, final product manufacturing, etc., can solve problems such as battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

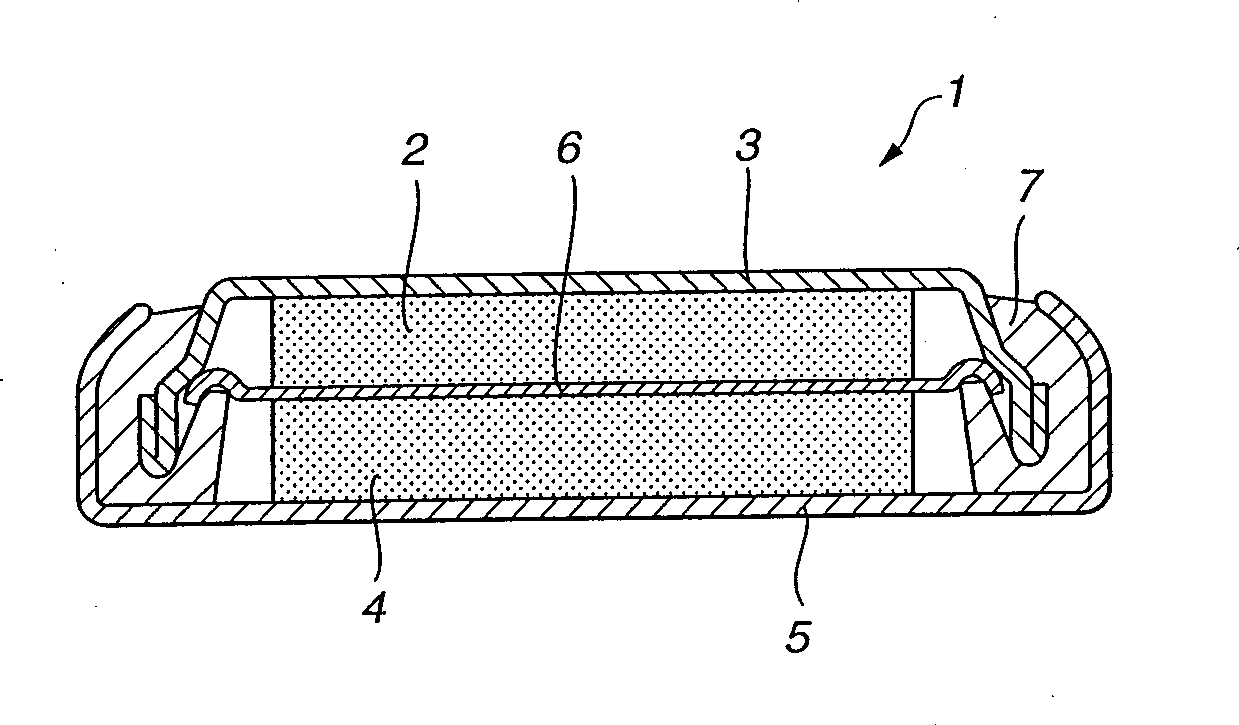

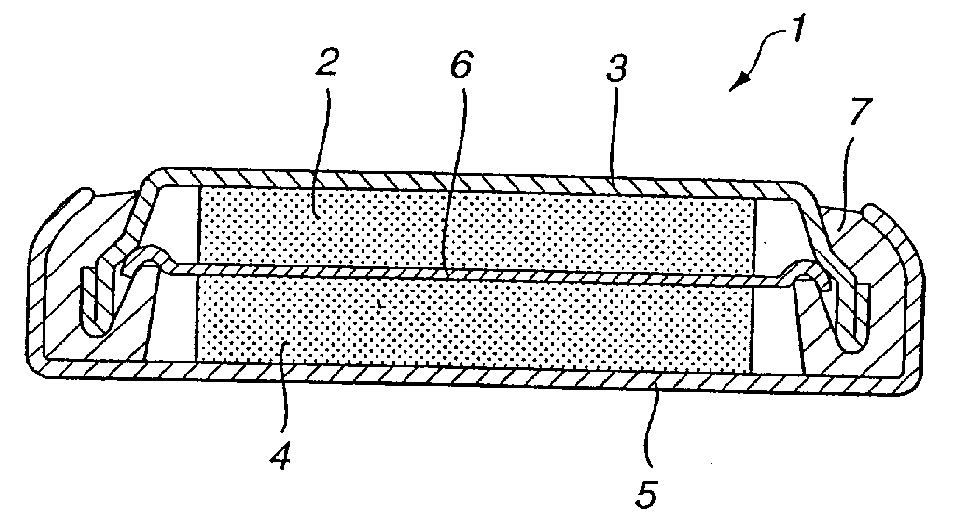

Image

Examples

Embodiment 1

[0054] Initially, the synthesis replaced LiMn with Cr 2 O 4 The spinel-type lithium manganese oxide substituted with Cr obtained from part of Mn is used as the cathode active material.

[0055] Use an agate mortar to put commercially available manganese dioxide (MnO 2 ) Powder, lithium carbonate (Li 2 CO 3 ) Powder and chromium oxide (Cr 2 O 3 ) The powders are mixed together, and Li, Cr and Mn are mixed in a mixing ratio of 1:0.2:1.8.

[0056] The resulting mixed powder was sintered in an electric furnace under atmospheric pressure to synthesize Cr-substituted spinel lithium manganese oxide. The sintering temperature at this time was set to 800°C. When analyzing the sample obtained by sintering the mixed powder by X-ray diffraction, the spectrum accurately corresponds to the LiMn described in ISDD card 35-782 2 O 4 The data.

[0057] Then, Cr-substituted spinel-type lithium manganese oxide is used as the cathode active material, graphite is used as the conductive material, and po...

Embodiment 2- Embodiment 4, comparative example 1 and comparative example 3

[0061] The coin-shaped battery was manufactured in the same manner as in Example 1, but the sintering temperature of the sintered mixed powder was set to the temperature shown in Table 1 below. Example 5-Example 8, Comparative Example 3 and Comparative Example 4

Embodiment 5- Embodiment 8

[0061] The coin-shaped battery was manufactured in the same manner as in Example 1, but the sintering temperature of the sintered mixed powder was set to the temperature shown in Table 1 below. Example 5-Example 8, Comparative Example 3 and Comparative Example 4

[0062] Initially, LiMn was replaced by Co in the synthesis 2 O4 Co-substituted spinel-type lithium manganese oxide obtained from part of Mn is used as a cathode active material.

[0063] Use an agate mortar to put commercially available manganese dioxide (MnO 2 ) Powder, lithium carbonate (Li 2 CO 3 ) Powder and cobalt oxide (Co 3 O 4 ) The powders are mixed together, and Li, Co and Mn are mixed in a mixing ratio of 1:0.2:1.8.

[0064] The resulting mixed powder was sintered in an electric furnace under atmospheric pressure, thereby synthesizing Co-substituted spinel-type lithium manganese oxide. The sintering temperature at this time was set to the temperature shown in Table 1 below.

[0065] A coin-shaped battery was m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com