Pdx@Pt/C core-shell structure cathode catalyst for fuel cell and preparation method of Pdx@Pt/C core-shell structure cathode catalyst

A fuel cell cathode, core-shell structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of difficult to achieve large-scale preparation, small amount of preparation, inability to achieve coating, etc., to improve uniformity and Utilization rate, area activity improvement, and area activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Its preparation method comprises steps:

[0029] 1) Add palladium precursor and conductive carrier to N,N-dimethylformamide or ethanol, after ultrasonic mixing, add borane N,N-diethylaniline or sodium borohydride, react at room temperature for 0.5- After 1.5 hours, after centrifugal washing and vacuum drying, a carbon-supported Pd catalyst, i.e. Pd / C, was obtained;

[0030] 2) Ultrasonic disperse the Pd / C prepared in the previous step in a formic acid solution with a concentration of 1-5ml formic acid / 20ml water, and add a platinum compound according to the atomic ratio of Pt to Pd at 1:1, 1:2 or 1:3 aqueous solution, react at room temperature for 2 to 6 hours, centrifuge and wash, and vacuum dry to obtain Pd x Pt / C core-shell catalyst.

Embodiment 1

[0032] 1) Pd x Preparation of Pt / C core-shell catalyst

[0033] Add palladium precursor and conductive carrier to N,N-dimethylformamide, add borane N,N-diethylaniline after ultrasonic mixing, react at room temperature for 1 hour, centrifuge and vacuum dry to obtain Carbon-supported Pd catalyst, that is, Pd / C; ultrasonically disperse the Pd / C prepared in the previous step in a very low concentration formic acid solution (1-5ml formic acid / 20ml water), and the atomic ratio of Pt and Pd is 1:1 , 1:2, 1:3 by adding an aqueous solution of potassium chloroplatinite, reacting at room temperature for 3 hours, washing by centrifugation, and drying in vacuum to obtain PdPt / C, Pd 1.4 Pt / C, Pd 2 Pt / C catalyst. Among them, PdPt / C, Pd 1.4 Pt / C, Pd 2 The Pt content of Pt / C core-shell nanocatalysts is about 35.8wt%, 25.9wt%, 19.5wt% of the catalyst. The obtained catalyst Pd x The particle size range of Pt / C is 3~6nm.

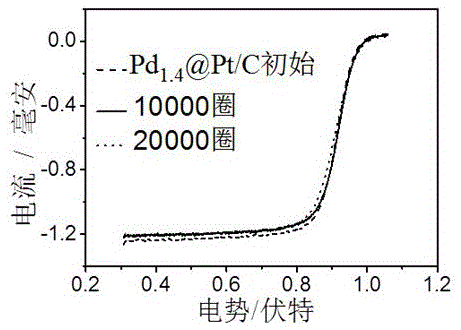

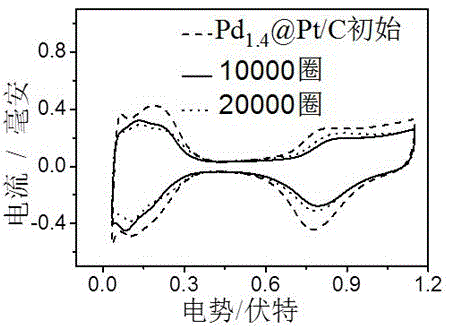

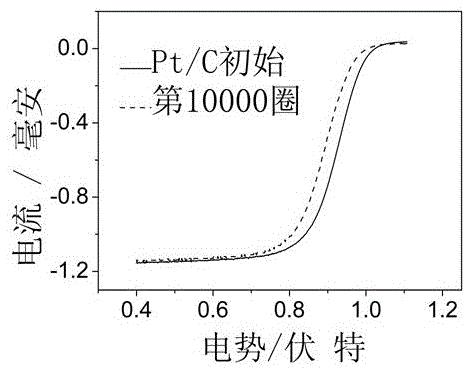

[0034] 2) Test Pd x Cathodic performance and stability of Pt / C co...

Embodiment 2

[0039] 1) Preparation of Pd-Pt / C non-core-shell catalyst

[0040] Add palladium precursor and conductive carrier to N,N-dimethylformamide, add borane N,N-diethylaniline after ultrasonic mixing, react at room temperature for 1 hour, centrifuge and vacuum dry to obtain Carbon-supported Pd catalyst, that is, Pd / C; ultrasonically disperse the Pd / C prepared in the previous step in a moderate concentration of formic acid solution (8-15ml formic acid / 20ml water), add potassium chloroplatinite solution, and react at room temperature for 3 Hours, centrifuged and washed, vacuum-dried to obtain the Pd-Pt / C catalyst. Among them, the Pt content of the Pd-Pt / C nanocatalyst is about 26wt% of the catalyst.

[0041] 2) Test the cathode performance of Pd-Pt / C non-core-shell catalyst

[0042] The electrode with Pd-Pt / C catalyst on the surface was inserted into the electrolyte as the working electrode. The electrochemical properties of the catalysts Pd-Pt / C and Pt / C were tested respectively us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com