Method for preparing high-performance fuel cell nanocomposite cathode material

A fuel cell, nanocomposite technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of reduced electrochemical performance, lack of ionic conductivity, etc., to improve cathode performance, raw materials Simple and easy to obtain, increase the effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation of material

[0025] (1) According to the molar ratio of citric acid to EDTA of 1.5:1, Er(NO 3 ) 3 ·6H 2 O, Bi(NO 3 ) 3 ·5H 2 The molar ratio of O and EDTA is 0.4:1.6:1.5, the ratio of 28% ammoniacal liquor volume and the molar number of EDTA 6ml:0.01mol, be dissolved in deionized water and keep stirring to obtain solution after making it fully dissolved;

[0026] (2) Stir the solution obtained in step (1) continuously at 375°C to completely evaporate the water, and then calcinate at 600°C for 3 hours to obtain the prepared ESB powder;

[0027] (3) According to the molar ratio of citric acid to EDTA of 1.5:1, La(NO 3 ) 3 ·6H 2 O and Sr(NO 3 ) 2 with Mn(NO 3 ) 2 The molar ratio to EDTA is 0.8:0.2:1:2, the ratio of the volume of 28% ammonia water to the molar number of EDTA is 6ml:0.01mol, dissolved in deionized water and stirred continuously to fully dissolve to obtain solution A, the pH value is 5.5;

[0028] (4) Stir the solu...

Embodiment 2

[0033] Embodiment 2: the preparation of material

[0034] (1) According to the molar ratio of citric acid to EDTA of 1.5:1, Er(NO 3 ) 3 ·6H 2 O, Bi(NO 3 ) 3 ·5H 2 The molar ratio of O and EDTA is 0.4:1.6:1.5, the ratio of 28% ammoniacal liquor volume and the molar number of EDTA 6ml:0.01mol, be dissolved in deionized water and keep stirring to obtain solution after making it fully dissolved;

[0035] (2) Stir the solution obtained in step (1) continuously at 375°C to completely evaporate the water, and then calcinate at 600°C for 3 hours to obtain the prepared ESB powder;

[0036] (3) Add citric acid, La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Mn(NO 3 ) 2 Dissolve in deionized water and stir continuously to make it fully dissolved to obtain a solution, wherein the molar ratio of metal ions to citric acid is 1:1.5, and the pH value is 3;

[0037] (4) Stir the solution A obtained in step (3) continuously at 200°C to evaporate part of the water to obtain colloid B;

[0038]...

Embodiment 3

[0040] Embodiment 3: the preparation of material

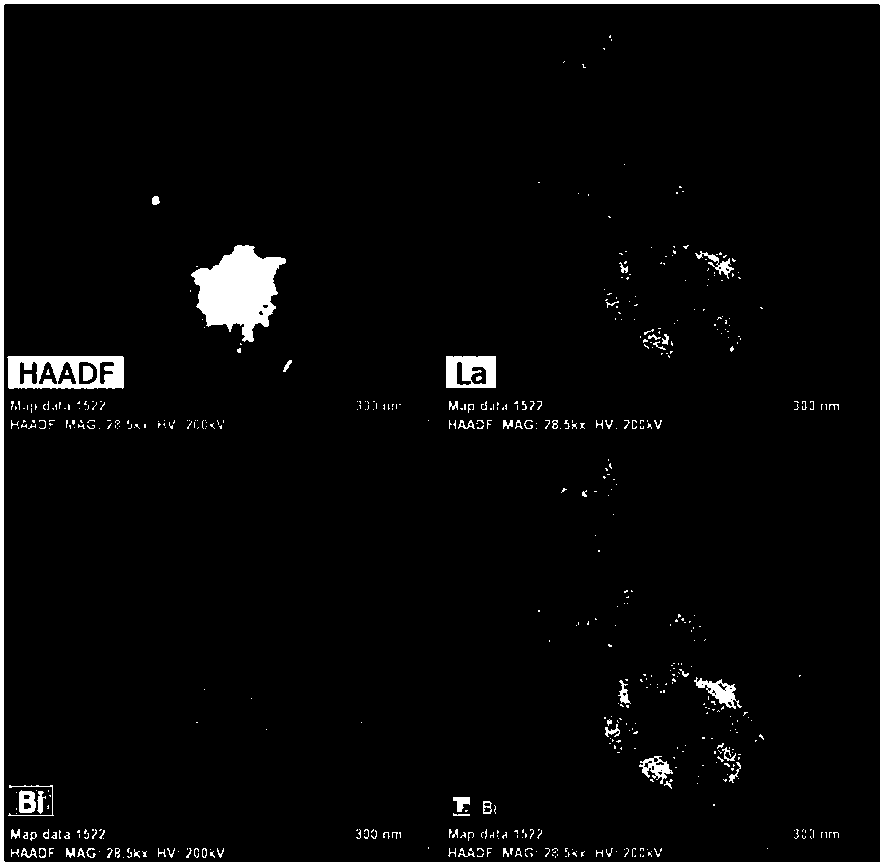

[0041] (1) According to the molar ratio of citric acid to EDTA of 1.5:1, Er(NO 3 ) 3 ·6H 2 O, Bi(NO 3 ) 3 ·5H 2 The molar ratio of O to EDTA is 0.396:1.584:2, the ratio of the volume of 28% ammonia water to the moles of EDTA is 6ml:0.01mol, dissolved in deionized water and continuously stirred to make it fully dissolved to obtain a solution, the pH value is 5.5;

[0042] (2) HfO 2 The powder is added to the solution obtained in step (1), HfO 2 The molar ratio of EDTA to EDTA is 0.01:2, and it is continuously stirred at 375°C to evaporate all the water, and then calcined at 600°C for 3 hours to obtain the prepared (Er 0.4 Bi 1.6 ) 0.99 f 0.01 o 3 Powder.

[0043] (3) According to the molar ratio of citric acid to EDTA of 1.5:1, La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Mn(NO 3 ) 2 The molar ratio to EDTA is 0.8:0.2:1:2, the ratio of the volume of 28% ammonia water to the molar number of EDTA is 6ml:0.01mol, dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com