Foamed nickel and iron carbon combination type biological filler and preparation method thereof

A technology of biological filler and nickel foam, which is applied in chemical instruments and methods, biological water/sewage treatment, electrochemical and biological combination treatment, etc., to achieve the effects of good sedimentation, easy biofilm formation, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation process of nickel foam 2 is: polyurethane foam → roughening → sensitization → activation → electroless nickel plating → electroforming nickel → pyrolysis → heat treatment. Coarsening with KMnO 4 +H 2 SO 4 The process makes the porosity rate reach more than 99%; sensitization and activation adopt conventional stannous chloride and palladium chloride process, electroless nickel plating adopts alkaline low-temperature nickel plating process with sodium hypophosphite as reducing agent; electroforming nickel adopts Nickel sulfate solution, the anode uses electrolytic nickel, the foam after electroless nickel plating is fixed on the conductive frame as the cathode, the power supply uses a silicon controlled rectifier that can be controlled by constant voltage and constant current; the foam mandrel skeleton is removed by heating and decomposition, and then reduced Ni foam 2 was obtained by heat treatment under atmosphere.

[0035] The specific operation step...

Embodiment 1

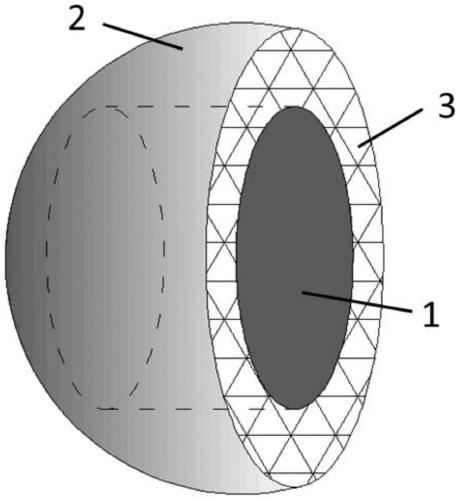

[0040] Such as figure 1 As shown, the combined biofiller of foamed nickel and iron-carbon particles of the present invention includes foamed nickel 2, and iron-carbon particles 1 coated with surface-distributed iron needle-like net 3 are fixed in the foamed nickel 2, and the foamed nickel 2 is a continuous foam For nickel, the pore diameter of the foamed nickel 2 is 0.5 mm to 1 mm, the thickness of the foamed nickel 2 is 1 mm to 2 mm, and the geometric size of the foamed nickel 2 is 15 mm×15 mm. The inner diameter of the iron-carbon particles 1 is 10mm-12mm, and the height of the iron-carbon particles 1 is 8mm-10mm. A piece of nickel foam 2 is coated with iron-like needle mesh 3 and iron-carbon particles 1 distributed on the surface, and the iron needle-like mesh 3 is used to support the nickel foam 2 . The nickel foam 2 is an ultra-thin flaky nickel foam 2, and the iron-carbon particle 1 is a cylindrical solid made by mixing iron-carbon powder.

[0041] The content of the t...

Embodiment 2

[0044] Under normal temperature conditions, the reactor will contain 100mg·Nm -3 and 120mg·Nm -3 Xylene and ethyl acetate mixed simulated waste gas 100L h -1 Pass it into the electrode biofilm reactor with the built-in biological filler, stay for 1min, and detect the purified tail gas. The result is that the removal efficiencies of xylene and ethyl acetate are 91.1% and 95.5% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com