Iron-carbon micro-electrolysis filler as well as preparation method and application thereof

A technology of iron-carbon micro-electrolysis and iron powder, which is applied in chemical instruments and methods, electrochemical and biological combination treatment, water pollutants, etc., can solve the problems that the effluent cannot meet the discharge standard, the effect of pollutants is poor, passivation, etc., and achieve Effect of improving electrochemical activity, long hydraulic retention time, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

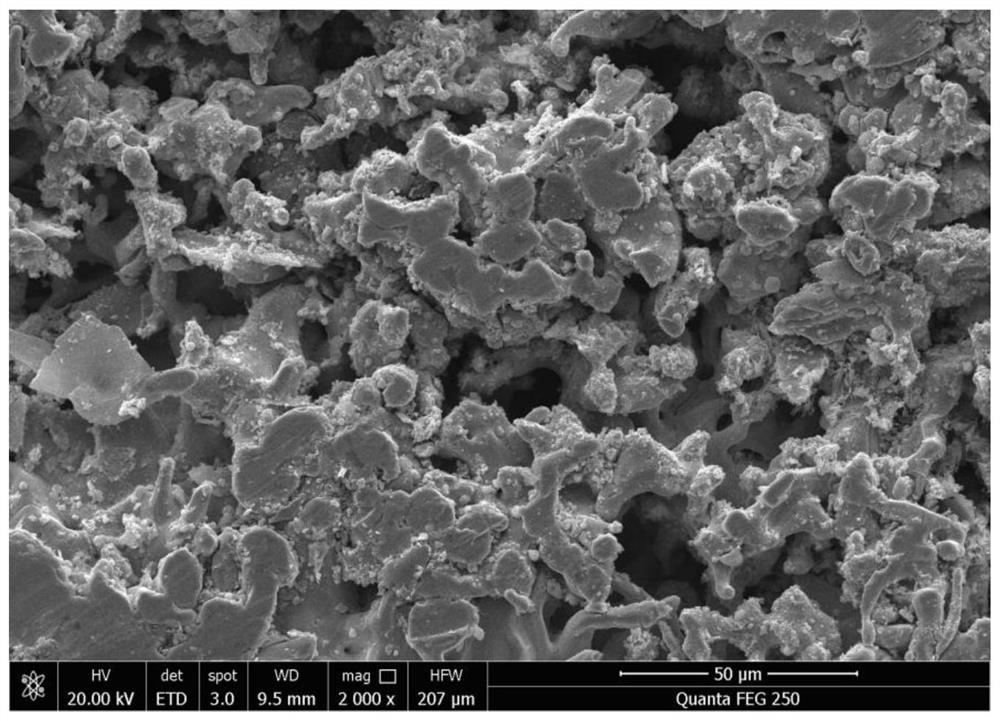

[0023] Embodiment 1. Preparation of iron-carbon micro-electrolytic filler:

[0024] (1) Preparation of raw materials:

[0025] Pass the iron powder, activated carbon powder, bentonite and manganese oxide through a 200-mesh sieve, and then dry them in an oven for half an hour.

[0026] (2) Stirring:

[0027] The powder is mixed according to the mass percentage of iron powder: activated carbon powder: bentonite: manganese oxide = 60:15:17:8, and stirred by a mixer for more than 1 hour to stir evenly.

[0028] (3) Add water to granulate:

[0029] Add ammonium bicarbonate solution with a mass percentage of 0.5%% to the mixed powder and stir evenly, add water at 10% of the mass of the mixed powder to make spherical particles of 10-20mm, then place them in an oven and dry at 100°C Dry more than 2h.

[0030] (4) Calcination:

[0031] Place the dried filler in a muffle furnace and calcinate it at 600°C for 0.5 hour in an air atmosphere to obtain an iron-carbon micro-electrolytic ...

Embodiment 2

[0033] Embodiment 2. Preparation of iron-carbon micro-electrolytic filler:

[0034] (1) Preparation of raw materials:

[0035] Pass iron powder, activated carbon powder, bentonite and manganese oxide through a 200-mesh sieve, and then put them in an oven to dry for half an hour.

[0036] (2) Stirring:

[0037] The powder is mixed according to the mass percentage of iron powder: activated carbon powder: bentonite: manganese oxide = 41:37:27:5, and stirred by a mixer for more than 1 hour to stir evenly.

[0038] (3) Add water to granulate:

[0039] Add 2% sodium bicarbonate solution to the mixed powder and stir evenly, add water 10% of the mixed powder mass to make 10~20mm spherical particles, then place them in an oven and dry at 105°C More than 2 hours.

[0040] (4) Calcination:

[0041] Place the dried filler in a muffle furnace and calcinate it at 500°C for 3 hours in an air atmosphere to obtain an iron-carbon micro-electrolytic filler.

Embodiment 3

[0042] Embodiment 3. Preparation of iron-carbon micro-electrolytic filler:

[0043] (1) Preparation of raw materials:

[0044] Pass iron powder, activated carbon powder, bentonite and manganese oxide through a 200-mesh sieve, and then put them in an oven to dry for half an hour.

[0045] (2) Stirring:

[0046] The powder is mixed according to the mass percentage of iron powder: activated carbon powder: bentonite: manganese oxide = 48:16:32:4, and stirred by a mixer for more than 1 hour to stir evenly.

[0047] (3) Add water to granulate:

[0048] Add 1% by mass sodium bicarbonate solution to the mixed powder and stir evenly, add 10% of the mass of the mixed powder with water to make 10-20mm spherical particles, then place them in an oven and dry at 105°C More than 2 hours.

[0049] (4) Calcination:

[0050] Place the dried filler in a muffle furnace and calcinate it at 500°C for 3 hours in an air atmosphere to obtain an iron-carbon micro-electrolytic filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com