Preparation method of LiFePO4/GO/Mx+/C composite

A composite material and material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem that lithium iron phosphate cannot improve electronic conductivity and ion diffusion rate, cannot solve the physical and chemical properties of nano-scale particles, and pollutes the environment. Employee health and other problems, to achieve the effect of high rate charge and discharge performance, low production material cost, and high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

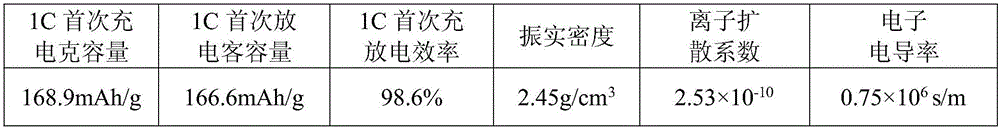

Embodiment 1

[0029] (1) Preparation of GO / Mg 2+ Material

[0030] Accurately weigh 6.0kg of water-based single-layer graphene emulsion with a particle size of 120-160nm 5%wt, 58.4g of magnesium hydroxide, and emulsify in the emulsification equipment for 1h. During the process, the temperature of the material is controlled at 50°C. Dry at a constant temperature of 330°C in a spray drying equipment protected by an inert gas.

[0031] (2) Preparation of LiFePO 4 / GO / Mg 2+ Material

[0032] After accurately weighing 5.9kg of lithium carbonate, 8.0kg of ferrous oxalate, 3.7kg of phosphoric acid, and 32.0kg of deionized water, mix with GO / Mg in step (1). 2+ The materials are added to a ball mill with 50.0kgΦ=30mm zirconia balls in a certain order and circulated for 6 hours. During the circular grinding process, the temperature of the materials in the ball mill is controlled at 30°C; after the materials are evenly mixed, they are transferred to a high-purity nitrogen-protected spray In the d...

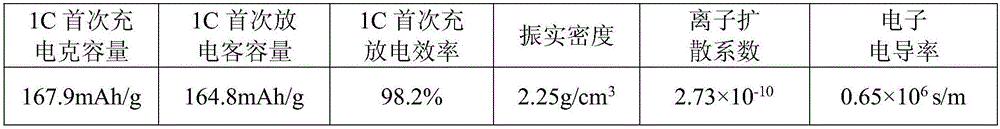

Embodiment 2

[0038] (1) Preparation of GO / Mn 4+ Material

[0039] Accurately weigh 6.0kg of water-based single-layer graphene emulsion with a particle size of 150-180nm 5%wt, 110.0g of manganese dioxide, and emulsify in the emulsification equipment for 1.5h. During the process, the temperature of the material is controlled at 45°C. Place in a spray drying equipment protected by an inert gas, and dry at a constant temperature of 320°C.

[0040] (2) Preparation of LiFePO 4 / GO / Mn 4+ Material

[0041] After accurately weighing 6.4kg of lithium carbonate, 8.0kg of ferrous oxalate, 3.7kg of phosphoric acid, and 40.0kg of deionized water, mix with GO / Mn in step (1). 4+ The materials are added to a ball mill with 75.0kgΦ=25mm zirconia balls in a certain order and circulated for 7 hours. During the circular grinding process, the temperature of the materials in the ball mill is controlled at 35°C; after the materials are evenly mixed, they are transferred to argon-protected spray drying. In th...

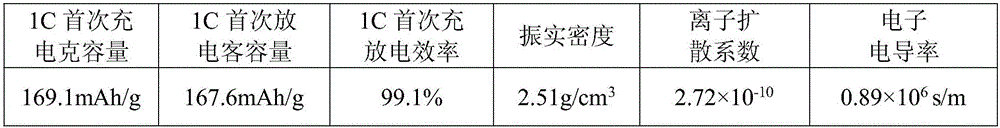

Embodiment 3

[0047] (1) Preparation of GO / Al 3+ Material

[0048] Accurately weigh 6.0kg of water-based graphene emulsion with a particle size of 120-160nm 5%wt, 203.0g of aluminum hydroxide, and emulsify in the emulsification equipment for 1h. During the process, the temperature of the material is controlled at 55°C. In the spray drying equipment protected by inert gas, it is dried at a constant temperature of 360°C.

[0049] (2) Preparation of LiFePO 4 / GO / Al 3+ Material

[0050] After accurately weighing 6.4kg of lithium carbonate, 8.0kg of ferrous oxalate, 3.7kg of phosphoric acid, and 32.0kg of deionized water, mix with GO / Al in step (1) 3+ The materials are added to a ball mill with 118.0kgΦ=35mm zirconia balls in a certain order and circulated for grinding for 6 hours. The temperature of the materials in the ball mill is controlled at 30°C during the circulation grinding process; after the materials are evenly mixed, they are transferred to a high-purity nitrogen-protected spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com