Preparation method of active porous graphene

A technology of porous graphene and graphene, which is applied in the field of preparation of active porous graphene, can solve the problems of low activity, poor electrical conductivity of graphene, and limited commercial application, and achieve high specific surface area, increased activity, and high magnification Effect of charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

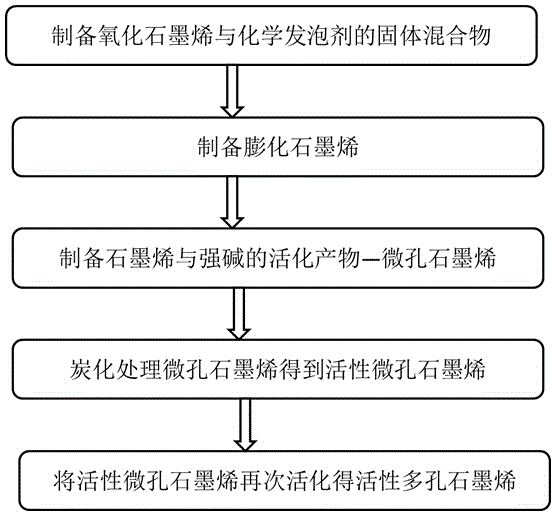

[0026] Such as figure 1 The preparation method of the shown active porous graphene is characterized in that: first, a solid mixture of graphene oxide and a chemical blowing agent is prepared. After that, the expanded graphene is prepared; next, the activated product of graphene and strong base is prepared. Subsequently, the active microporous graphene is prepared; finally, the finished product is obtained through the second pore forming.

[0027] As far as a preferred embodiment of the present invention is concerned, the process involved in preparing the solid mixture of graphene oxide and chemical foaming agent is: adding graphite oxide to a mixed solution of water and ethanol at pH=9 to 10, the The volume ratio of the mixed solution of water and ethanol is 2:1. Afterwards, stirring by magnetic force for 1 to 10 hours, and then ultrasonically dispersing for 0.5 to 2 hours to form a graphene oxide colloidal dispersion. During this period, the concentration of graphene oxide...

Embodiment 1

[0032] Add 0.1g of graphite oxide to 200mL of water and ethanol mixed solution (the volume ratio of water and ethanol is 2:1), and stir magnetically for 2 hours. Thereafter, ultrasonic dispersion was performed for 0.5 hours to form a graphene oxide colloidal dispersion. Then, 0.4 g of ammonium bicarbonate was added, stirred for 2 hours, excess ammonium bicarbonate was removed by filtration, and a solid mixture of graphene oxide and ammonium bicarbonate was obtained after drying. Subsequently, the solid mixture was placed in a tube furnace for puffing reduction in a reducing atmosphere of hydrogen and nitrogen.

[0033] Specifically, during the expansion and reduction period, gradually increase from room temperature to 500°C, control the heating rate to 8°C / min, and hold at 200°C for 15 minutes, and then hold at 500°C for 1.5 hours to obtain expanded graphene .

[0034] Subsequently, the expanded graphene was mixed with sodium hydroxide, and heated at 450° C. for 1 hour to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com