High temperature and high salinity resistant plugging control system and plugging control method by using same

A high-temperature-resistant, systematic technology, applied in chemical instruments and methods, earth drilling, and drilling compositions, etc., can solve problems such as unsatisfactory long-term effectiveness, poor plugging strength, and particle softening, and achieve long-term validity , high compressive strength and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: The plugging control system forms titanium salt whiskers to realize the method of plugging control

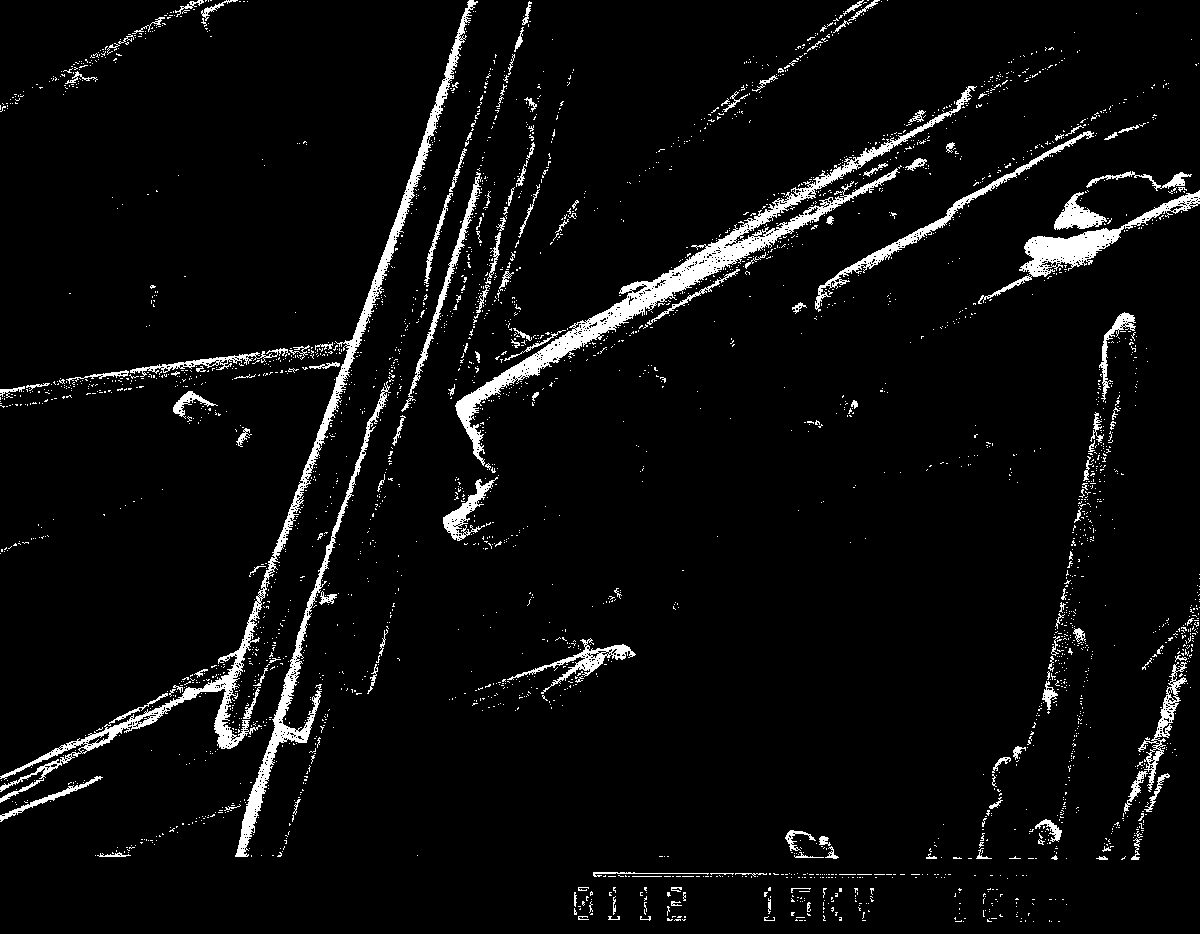

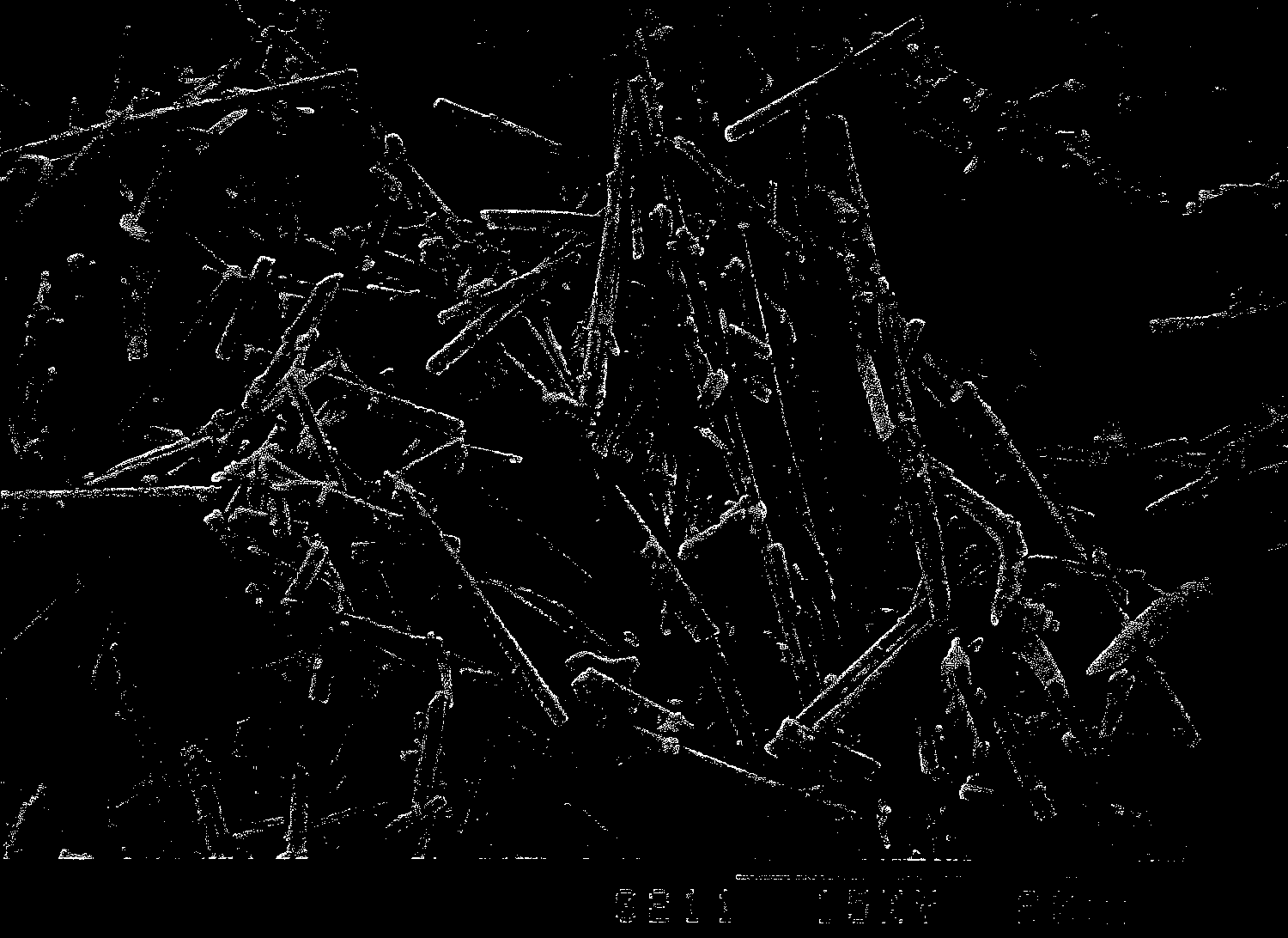

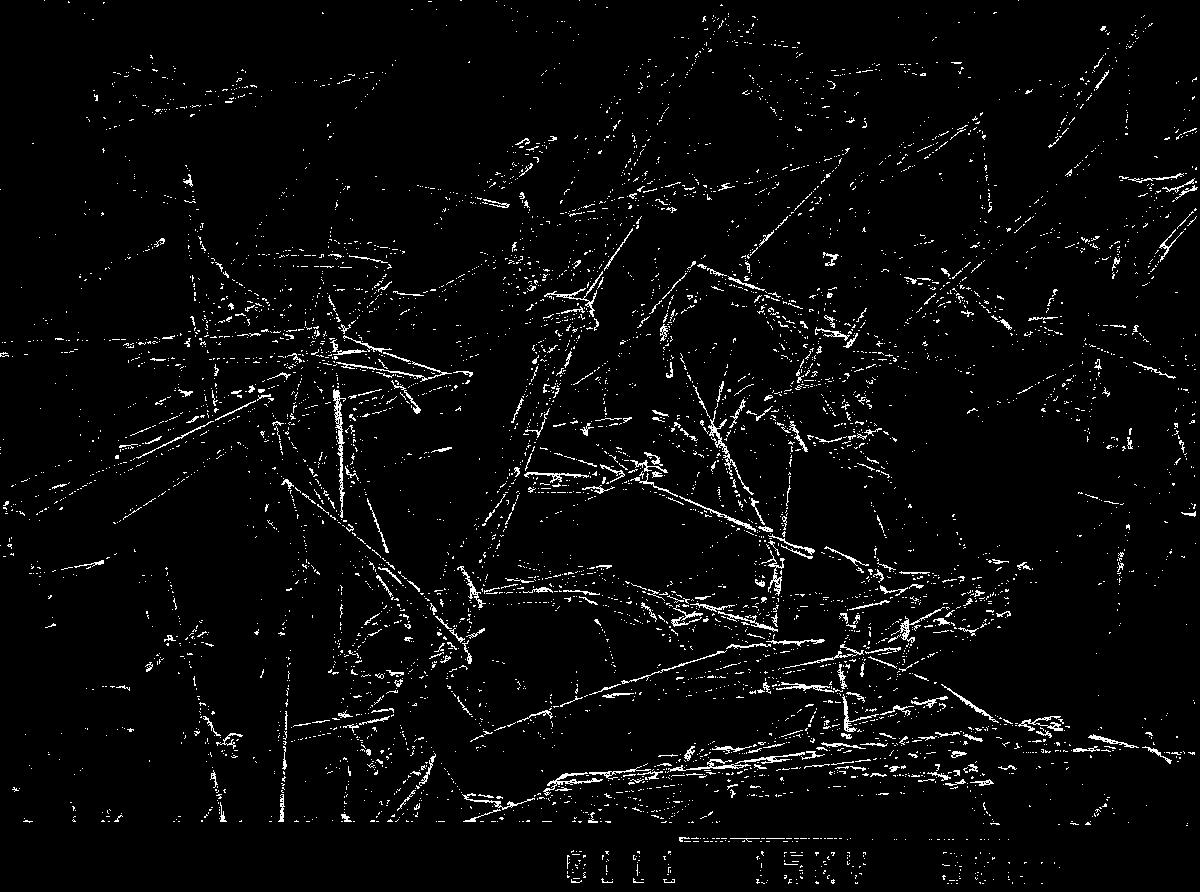

[0034] This plugging adjustment system is composed of A and B solutions. A solution is potassium chloride and titanium trichloride, and B solution is sodium sulfide. The B and A solutions are alternately injected into the natural rock core at a pressure of 0.1MPa to 200MPa and a temperature of 30°C to 600°C. Titanium salt whiskers can be obtained at ℃: 2TiCl 3 +3K 2 CO 3 = Ti 2 CO 3 +6KCl. Formation water is sodium bicarbonate water type, so there is a large amount of HCO3 in the water - , S in solution B 2- The ions react with it to form CO 3 2- Provide CO to the system 3 2- . The purpose of KCl is to adjust the salinity of the solution and avoid dissolving underground rocks after being injected into the ground, such as Figure 1-Figure 3 shown. figure 1 The microscopic picture of the whiskers is given, and it can be seen that the microscopic cry...

Embodiment 2

[0036] Plugging adjustment effect experiments under high temperature conditions and different permeability

[0037] 1. Experimental materials

[0038] Plugging adjustment system: composed of A and B solutions, A solution is potassium chloride and titanium trichloride, B solution is sodium sulfide;

[0039] Rock cores: artificial rock cores 1, 2, 3, and 4. The physical parameters of each artificial rock core are shown in Table 1;

[0040] Table 1 Core physical parameters

[0041]

[0042] Fork 12 simulates formation water: as shown in Table 2.

[0043] Table 2 Ion concentration of simulated formation water in Cha12

[0044]

[0045] 2. Experimental method

[0046] (1) Put the artificial cores 1, 2, 3, and 4 into the core holder respectively, open the thermostat, set the temperature to 90°C, and proceed to step (2) after the temperature is stable;

[0047] (2) Set confining pressure 1MPa-20MPa, injection rate 0.025m / d-10m / d (meter / day), open the intermediate container...

Embodiment 3

[0063] Example 3: Comparative example of the plugging control system of Example 2 and the scheduling effect of the polymer gel

[0064] 1. Experimental materials and methods

[0065] Polymer gel system solution (the polymer is polyacrylamide, the concentration is 1200mg / L; the crosslinking agent is chromium ion crosslinking agent, the concentration is 60mg / L; that is, the polycross ratio is 20:1), the diameter is 2.5 inches Rock core, the physical properties of the rock core are shown in Table 5, and the formation water uses Cha 12 formation water (same as Example 2). The experimental temperature is 90°C. The injection volume is 0.5PV.

[0066] Table 5 Core physical properties

[0067]

[0068] The polymer gel system is injected into the core, and when a certain amount of the polymer gel system solution is injected, the system is sealed and kept at a constant temperature until the system is completely gelled. Follow-up water flooding was carried out, and the pressure ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com