Chromium-free antitarnish adhesion promoting treatment composition

a technology of adhesion-promoting treatment and composition, which is applied in the direction of metal adhesion improvement, transportation and packaging, and other domestic articles, can solve the problems of increasing scrutiny of cr (vi) and failures in produced devices, and achieve the effect of enhancing adhesion of a polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

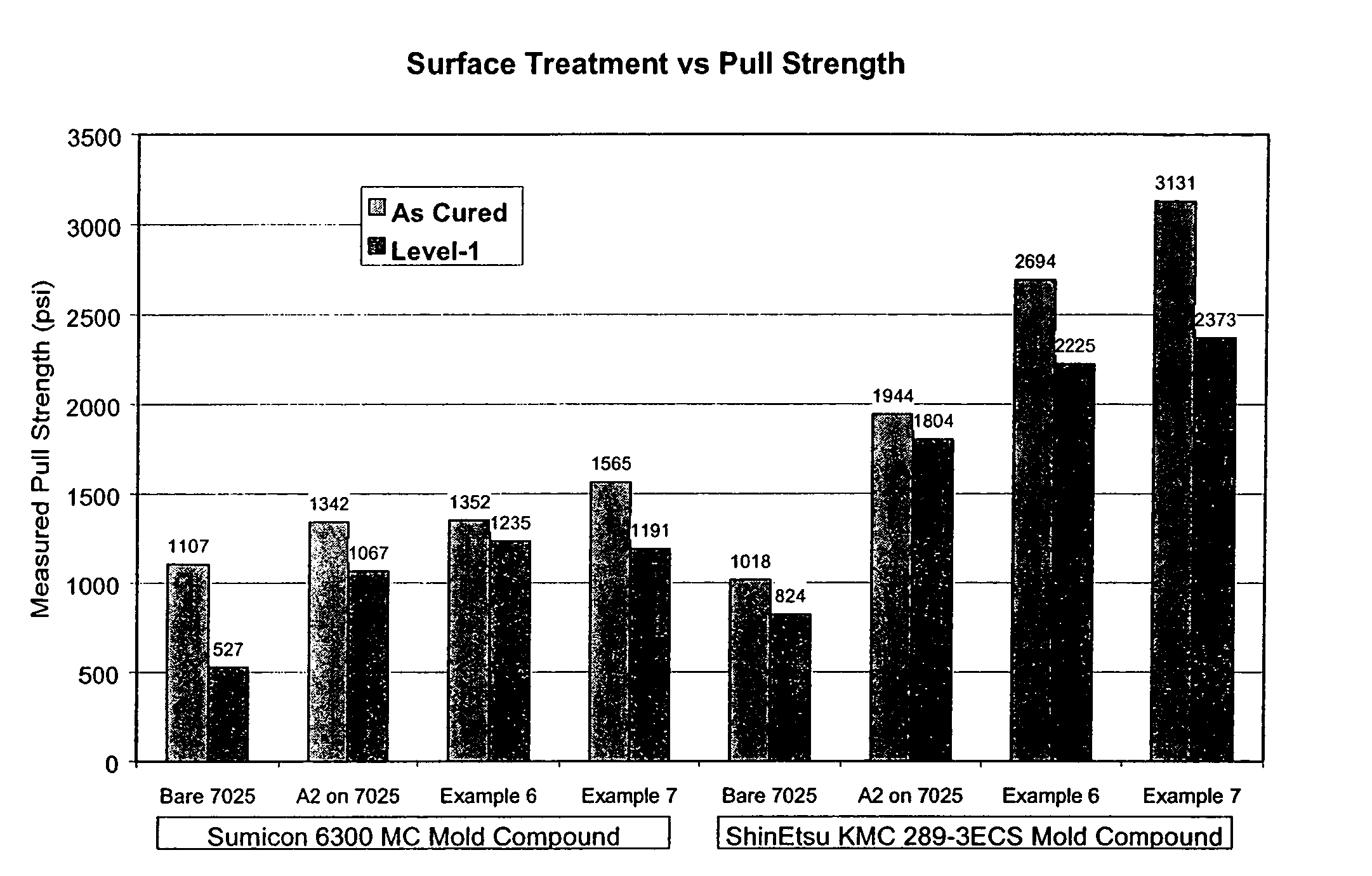

[0043] A C110 copper foil (>99.9% Cu and 4.7H2O, 10 g / L (NH4)2SO4 and 25 ppm W (tungsten, as tungstosilicic acid). A plating current of 10 amperes per square foot (ASF) was applied to an area of 0.035 ft2 for 2, 5 and 10 second intervals. The sample was then rinsed and dried. FIGS. 1(a), 1(b), and 1(c) show scanning electron micrographs (SEMs) of the treated surfaces at the three time intervals. In each case, the nodular morphology is visible.

[0044] The copper foil sample was subjected to a tape test using a Scotch 600 tape. The tape was first pressed onto the plated surface and then pulled away from the surface. The glue was visibly left behind on the plated sample, indicating that a nodular structure was deposited onto the copper foil.

[0045] The sample was further subjected to a 250° C. bake for 30 minutes. The sample showed no oxidation after the bake, while an untreated portion was heavily oxidized. This result indicated that the deposited coating provided a good tarnish resis...

example 2

[0046] A C110 copper foil sample having pure copper dendrites on one side and bare on the other was dipped in 5 wt % H2SO4 for 30 seconds to remove any existing surface oxides. The sample was placed in a fixture that exposes only one surface to an aqueous plating composition containing 10 g / l ZnSO4.7H2O, 20 g / l (NH4)2SO4 and 25 ppm W, and a plating current of 10 ASF was applied to an area of 0.104 ft2 for 5 sec. The sample was then rinsed and dried. The procedure was repeated on a second sample exposing the opposite surface to the same solution and plating current. The samples were further subjected to a 95° C. / 55% RH test for 60-min to simulate a long-term storage in a hot and humid condition. The sample was subsequently baked for 30 min at 190° C. and showed no oxidation. The untreated portion was heavily oxidized. This indicated that the coating provided a good tarnish resistance.

example 3

[0047] A C110 copper foil was electrocleaned in a commercial alkaline cleaner to remove the residual lubricant, contaminants, and oxides from the surface. A plating current of 5 ASF was applied to an area of 0.035 ft2 for 5 sec in a solution containing 5 g / l ZnSO4.7H2O, 3 g / l NiSO4.6H2O, 50 ml KMnO4 N / I 0 and 2.5 ml / l MITIQUE (inorganic acid composition that contains 1-3% ammonium molybdate; Hubbard Hall, Waterbury, Conn.). The sample was then rinsed and dried, and subjected to a tape test using a Scotch 600 tape. The tape was first pressed onto the plated surface and then pulled away from the surface. The glue was visibly left behind on the plated sample. This result indicates that a nodular structure was deposited.

[0048] The sample was further subjected to a 250° C.×10-min bake test and the sample showed no oxidation after the bake. The untreated portion was heavily oxidized. This result indicated that the coating provided a good tarnish resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| RH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com