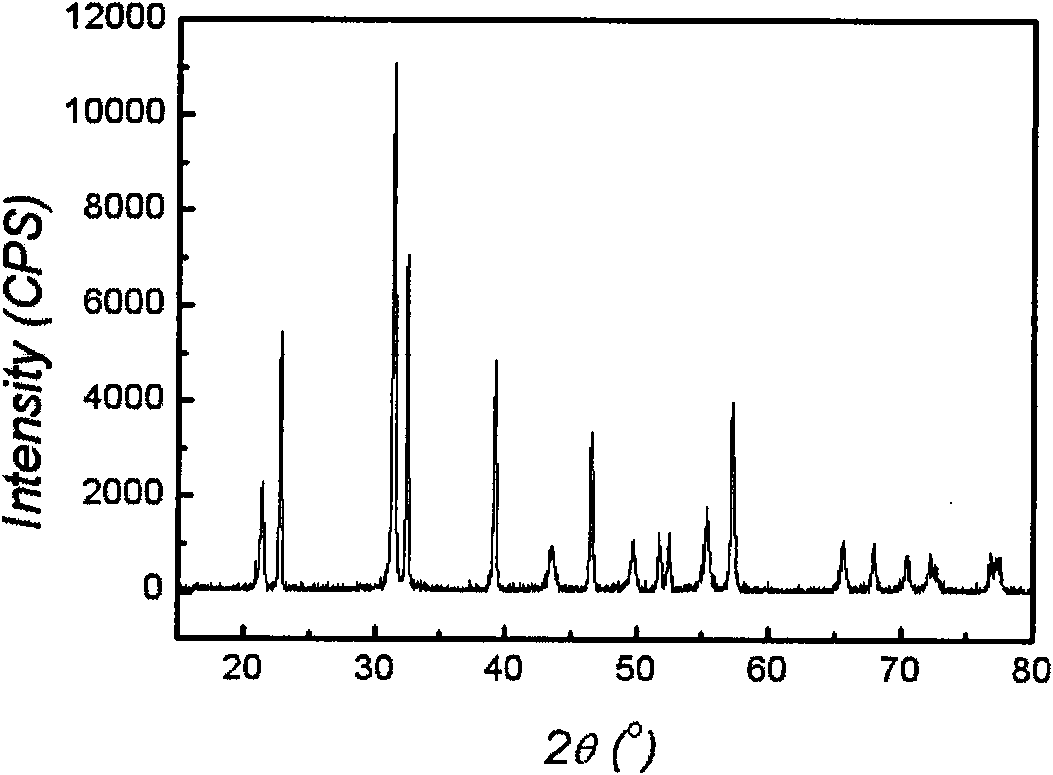

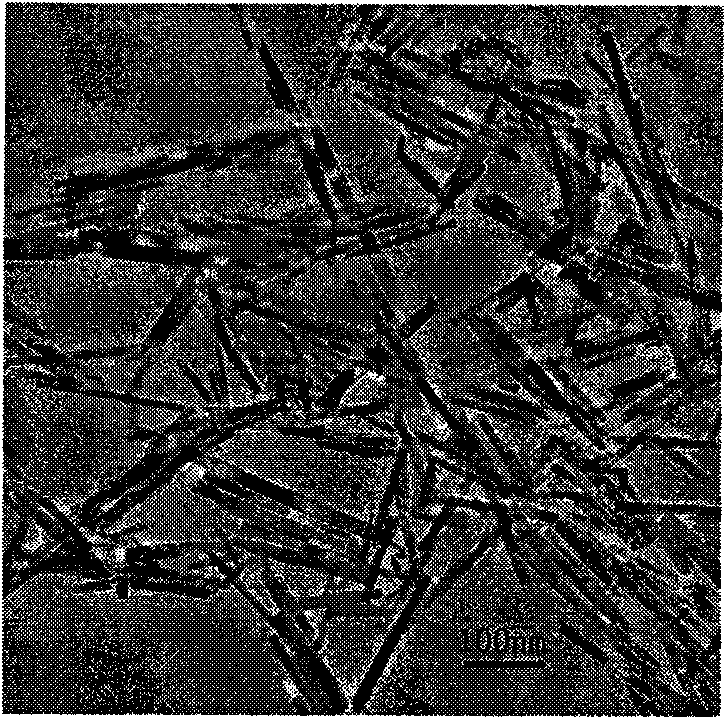

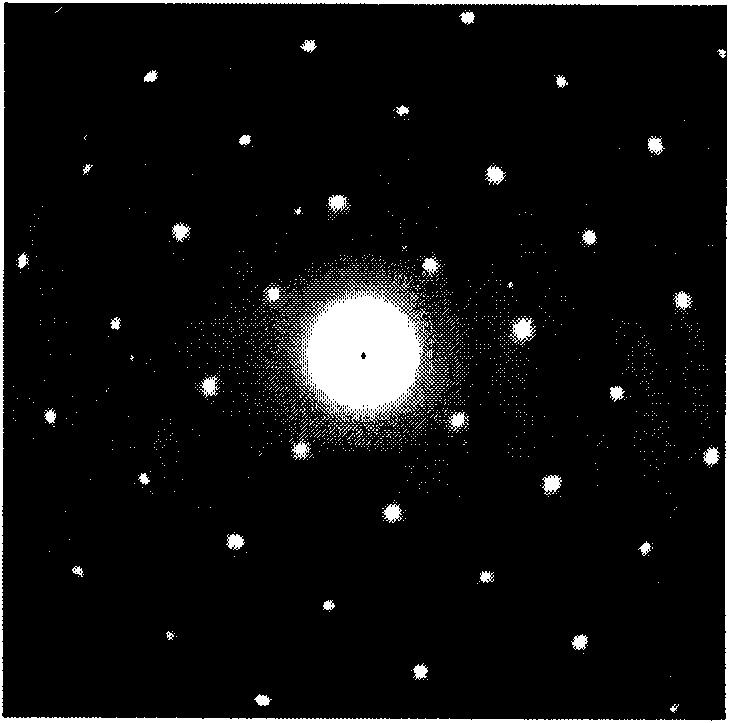

Method for preparing perovskite structure lead titanate monocrystal nano rod

A technology of perovskite structure and single crystal nanometer, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of difficult one-dimensional nanostructure preparation, small structural anisotropy, and difficult orientation growth and other issues, to achieve the effect of easy large-scale production, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] 1) According to the chemical formula PbTiO of the lead titanate single crystal nanorods to be synthesized 3 Measure and weigh titanium sulfate and lead nitrate and dissolve them in deionized water to prepare Ti 4+ Titanium sulfate aqueous solution and Pb with an ion concentration of 0.3 mol / L 2+ An aqueous solution of lead nitrate with an ion concentration of 0.1 mol / L.

[0022] 2) Take the amount of titanium sulfate and lead nitrate in the titanium sulfate aqueous solution and lead nitrate aqueous solution prepared in step 1) as the base, and measure the chemical reaction of titanium sulfate, lead nitrate and potassium hydroxide to form titanium hydroxide and lead hydroxide, Weigh potassium hydroxide and dissolve it in deionized water to prepare a potassium hydroxide aqueous solution with a concentration of 0.2 mol / L.

[0023] 3) While stirring, first add the titanium sulfate aqueous solution and the lead nitrate aqueous solution prepared in step 1) dropwise to the potassium...

example 2

[0026] 1) According to the chemical formula PbTiO of the lead titanate single crystal nanorods to be synthesized 3 Measure and weigh titanium sulfate and lead nitrate and dissolve them in deionized water to prepare Ti 4+ Titanium sulfate aqueous solution and Pb with an ion concentration of 0.1 mol / L 2+ Lead nitrate aqueous solution with an ion concentration of 0.3 mol / L.

[0027] 2) Take the amount of titanium sulfate and lead nitrate in the titanium sulfate aqueous solution and lead nitrate aqueous solution prepared in step 1) as the base, and measure the chemical reaction of titanium sulfate, lead nitrate and potassium hydroxide to form titanium hydroxide and lead hydroxide, Weigh potassium hydroxide and dissolve it in deionized water to prepare a potassium hydroxide aqueous solution with a concentration of 0.6 mol / L.

[0028] 3) While stirring, first add the titanium sulfate aqueous solution and the lead nitrate aqueous solution prepared in step 1) dropwise to the potassium hydro...

example 3

[0031] 1) According to the chemical formula PbTiO of the lead titanate single crystal nanorods to be synthesized 3 Measure and weigh titanium sulfate and lead nitrate and dissolve them in deionized water to prepare Ti 4+ Titanium sulfate aqueous solution and Pb with an ion concentration of 0.2mol / L 2+ Lead nitrate aqueous solution with ion concentration of 0.2mol / L.

[0032] 2) Take the amount of titanium sulfate and lead nitrate in the titanium sulfate aqueous solution and lead nitrate aqueous solution prepared in step 1) as the base, and measure the chemical reaction of titanium sulfate, lead nitrate and potassium hydroxide to form titanium hydroxide and lead hydroxide, Weigh potassium hydroxide and dissolve it in deionized water to prepare an aqueous potassium hydroxide solution with a concentration of 0.4 mol / L.

[0033] 3) While stirring, first add the titanium sulfate aqueous solution and the lead nitrate aqueous solution prepared in step 1) dropwise to the potassium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com