Method for preparing antibacterial active titanium oxide nanotube array composite coating material

A technology of titanium oxide nanotubes and composite coatings, applied in coatings, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of no antibacterial properties and limited applications, and achieve growth and nutrient transfer, The effect of reducing differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

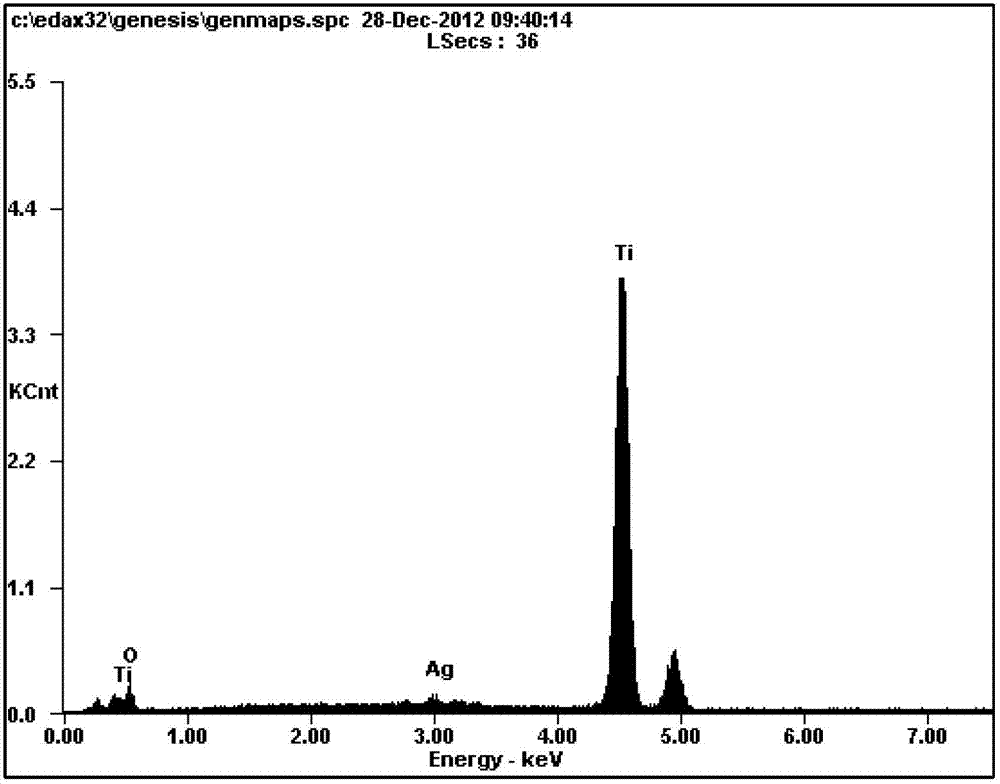

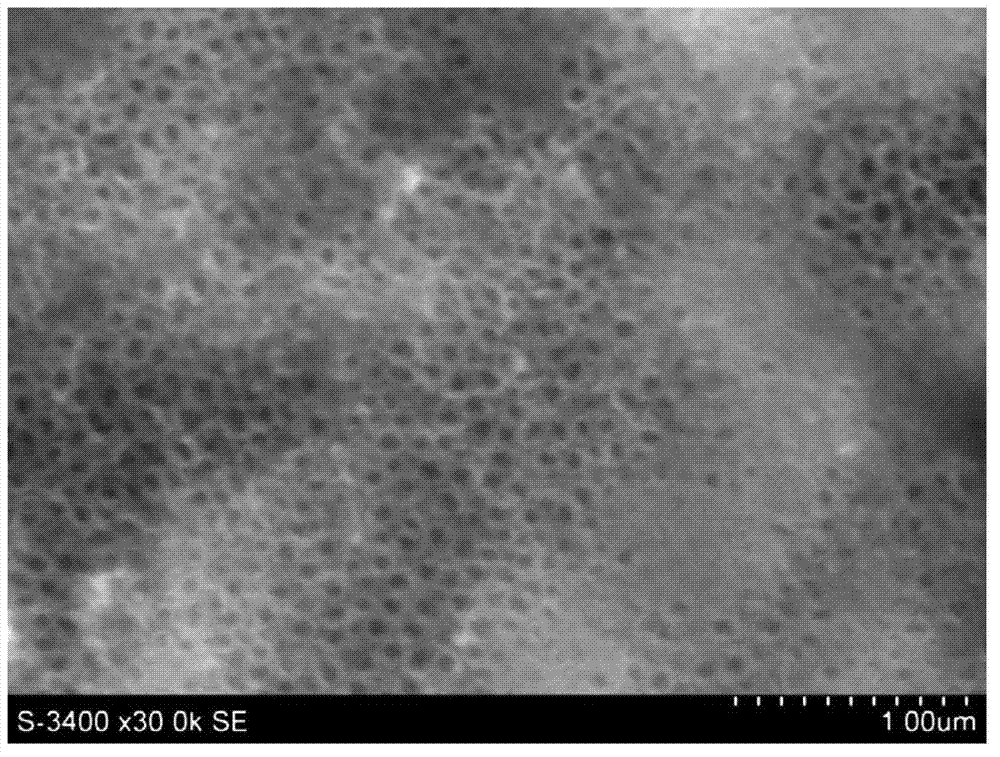

[0022] A preparation of an antibacterial and active titanium oxide nanotube array composite coating material, the specific steps are as follows:

[0023] (1) Preparation of active titanium oxide nanotube array: use pure titanium as the substrate, the surface is polished with metallographic sandpaper, cleaned, and dried as the anode, and the spectroscopically pure graphite sheet is used as the cathode, with 5g / LNa 2 HPO 4 The 0.5wt% HF solution is used as the electrolyte, which is taken out after anodizing at 20V for 20 minutes, dried and kept at 500°C for 1 hour, and cooled with the furnace;

[0024] (2), AgNO 3 Preparation of soaking solution: Weigh polyethylene glycol, potassium nitrate and silver nitrate at one time and dissolve them in distilled water to prepare a solution containing AgNO 3 0.1 mol·L -1 , containing polyethylene glycol 11.8 g L -1 , containing potassium nitrate 10g L -1 mixed solution;

[0025] (3), Soaking: Soaking with AgNO at 25°C 3 0.1 mol·L -...

Embodiment 2

[0029] A preparation of an antibacterial and active titanium oxide nanotube array composite coating material, the specific steps are as follows:

[0030] (1) Preparation of active titanium oxide nanotube array: use titanium alloy Ti6Al4V as the substrate, the surface is polished, cleaned and dried by metallographic sandpaper as the anode, and the spectroscopically pure graphite sheet is used as the cathode, with a concentration of 10g / LNa 2 HPO 4 The 0.5wt% HF solution is used as the electrolyte, which is taken out after anodizing at 20V for 40min, dried and kept at 500°C for 2 hours, and cooled with the furnace.

[0031] (2), AgNO 3 Preparation of soaking solution: Weigh polyethylene glycol, potassium nitrate and silver nitrate at one time and dissolve them in distilled water to prepare a solution containing AgNO30.1 mol L -1 , containing polyethylene glycol 5.9 g L -1 , containing potassium nitrate 5g·L -1 mixed solution;

[0032] (3), Soaking: Soaking AgNO at 20°C 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com