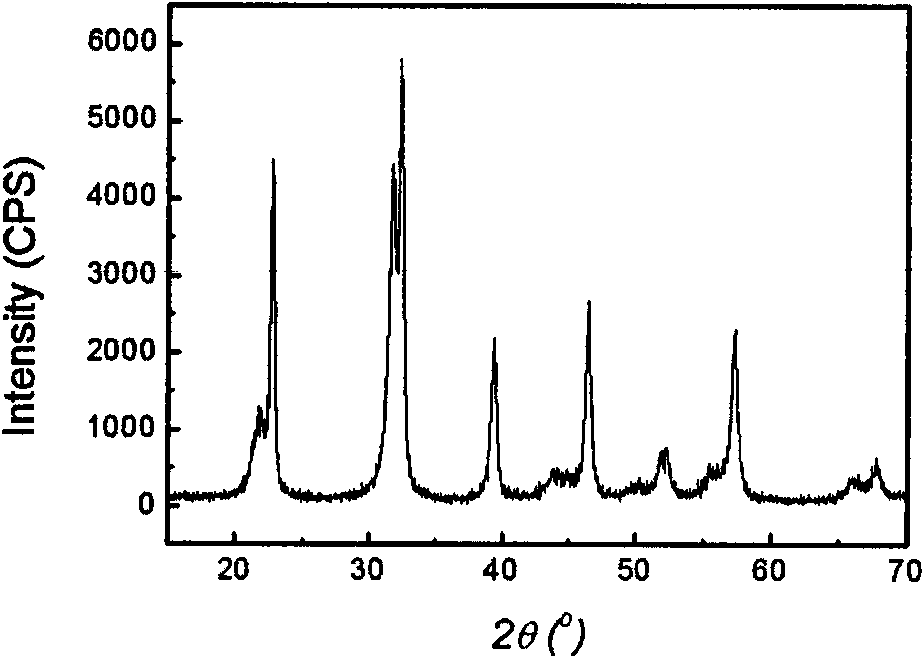

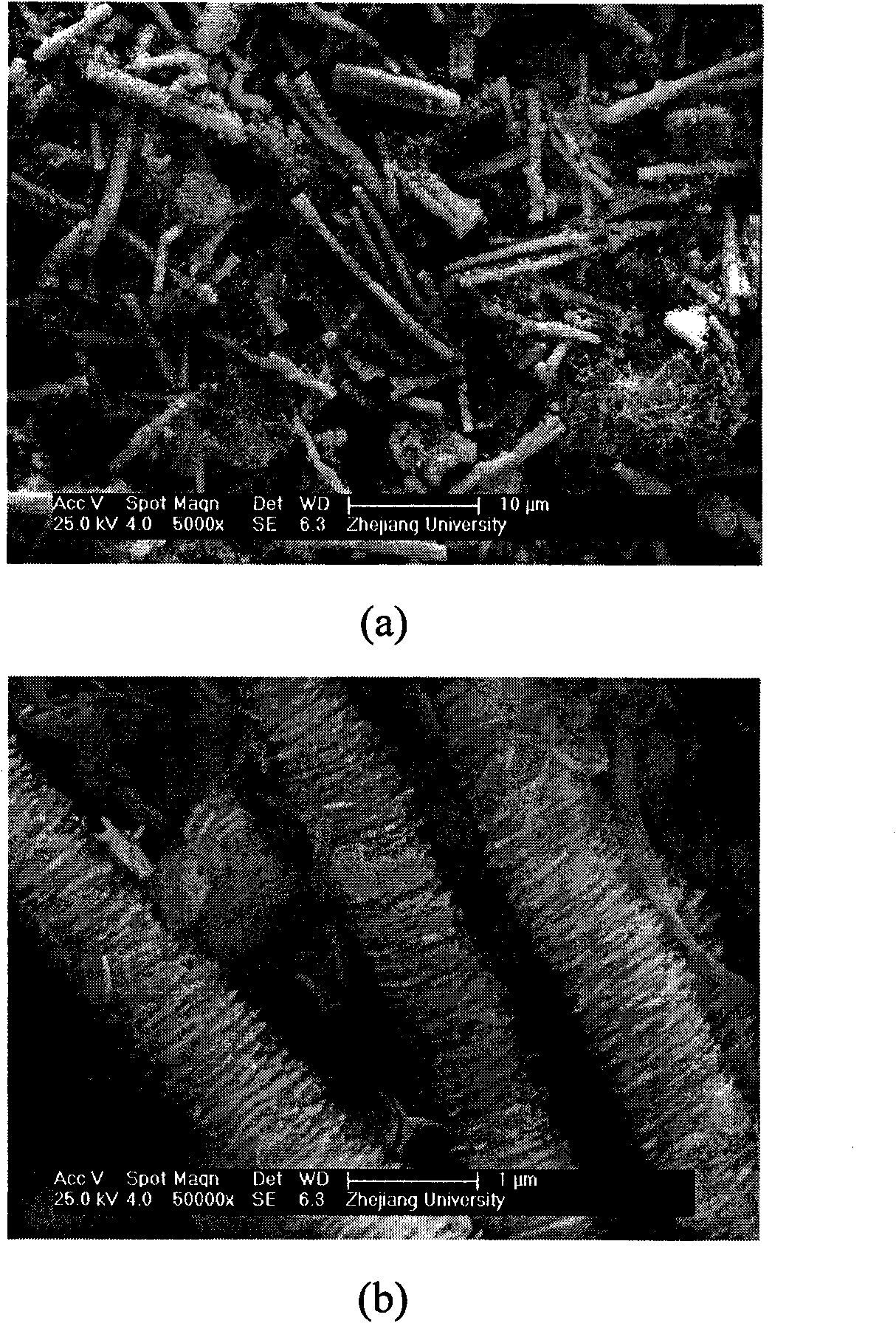

Method for preparing lead titanate nano column automatically assembled by perovskite structure nano pieces

A perovskite structure, lead titanate technology, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., to achieve the effects of easy control, simple process and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] 1) According to the chemical formula PbTiO of the lead titanate nanorod to be synthesized 3 Measure and weigh tetrabutyl titanate and lead nitrate, dissolve them in absolute ethanol and deionized water respectively, prepare the absolute ethanol solution of tetrabutyl titanate and the aqueous solution of lead nitrate, and adjust the Ti in the solution 4+ ions and Pb 2+ The ion concentration is 0.1mol / L.

[0024] 2) In the state of stirring, the ammonia solution with a concentration of 0.1mol / L is added dropwise to the ethanol solution of tetrabutyl titanate prepared in step 1), so that the tetrabutyl titanate is hydrolyzed, and titanium ions are precipitated to obtain A suspension containing titanium oxyhydroxide precipitates; the volume ratio of the ammonia solution used to the ethanol solution of tetrabutyl titanate is 0.5;

[0025] 3) In the state of stirring, continue to add ammonia solution to the suspension containing titanium oxyhydroxide precipitate prepared in...

example 2

[0030] 1) According to the chemical formula PbTiO of the lead titanate nanorod to be synthesized 3 Measure and weigh tetrabutyl titanate and lead nitrate, dissolve them in absolute ethanol and deionized water respectively, prepare the absolute ethanol solution of tetrabutyl titanate and the aqueous solution of lead nitrate, and adjust the Ti in the solution 4+ ions and Pb 2+ The ion concentration is 0.3mol / L.

[0031] 2) In the state of stirring, the ammonia solution with a concentration of 0.6mol / L is added dropwise to the ethanol solution of tetrabutyl titanate prepared in step 1), so that the tetrabutyl titanate is hydrolyzed, and titanium ions are precipitated to obtain The suspension of the oxyhydroxide precipitation of titanium; The volume ratio of the ammonia solution used and the ethanol solution of tetrabutyl titanate is 1.0;

[0032]3) In the state of stirring, continue to add ammonia solution to the suspension containing titanium oxyhydroxide precipitate prepared ...

example 3

[0037] 1) According to the chemical formula PbTiO of the lead titanate nanorod to be synthesized 3 Measure and weigh tetrabutyl titanate and lead nitrate, dissolve them in absolute ethanol and deionized water respectively, prepare the absolute ethanol solution of tetrabutyl titanate and the aqueous solution of lead nitrate, and adjust the Ti in the solution 4+ ions and Pb 2+ The ion concentration is 0.25mol / L.

[0038] 2) In the state of stirring, the ammonia solution with a concentration of 0.4mol / L is added dropwise to the ethanol solution of tetrabutyl titanate prepared in step 1), so that the tetrabutyl titanate is hydrolyzed, and titanium ions are precipitated to obtain The suspension of the oxyhydroxide precipitation of titanium; The volume ratio of the ammonia solution used and the ethanol solution of tetrabutyl titanate is 1.5;

[0039] 3) In the state of stirring, continue to add ammonia solution to the suspension containing titanium oxyhydroxide precipitate prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com