Method for preparing mesoporous crystal titanium dioxide using light-sensitive active matter as formboard

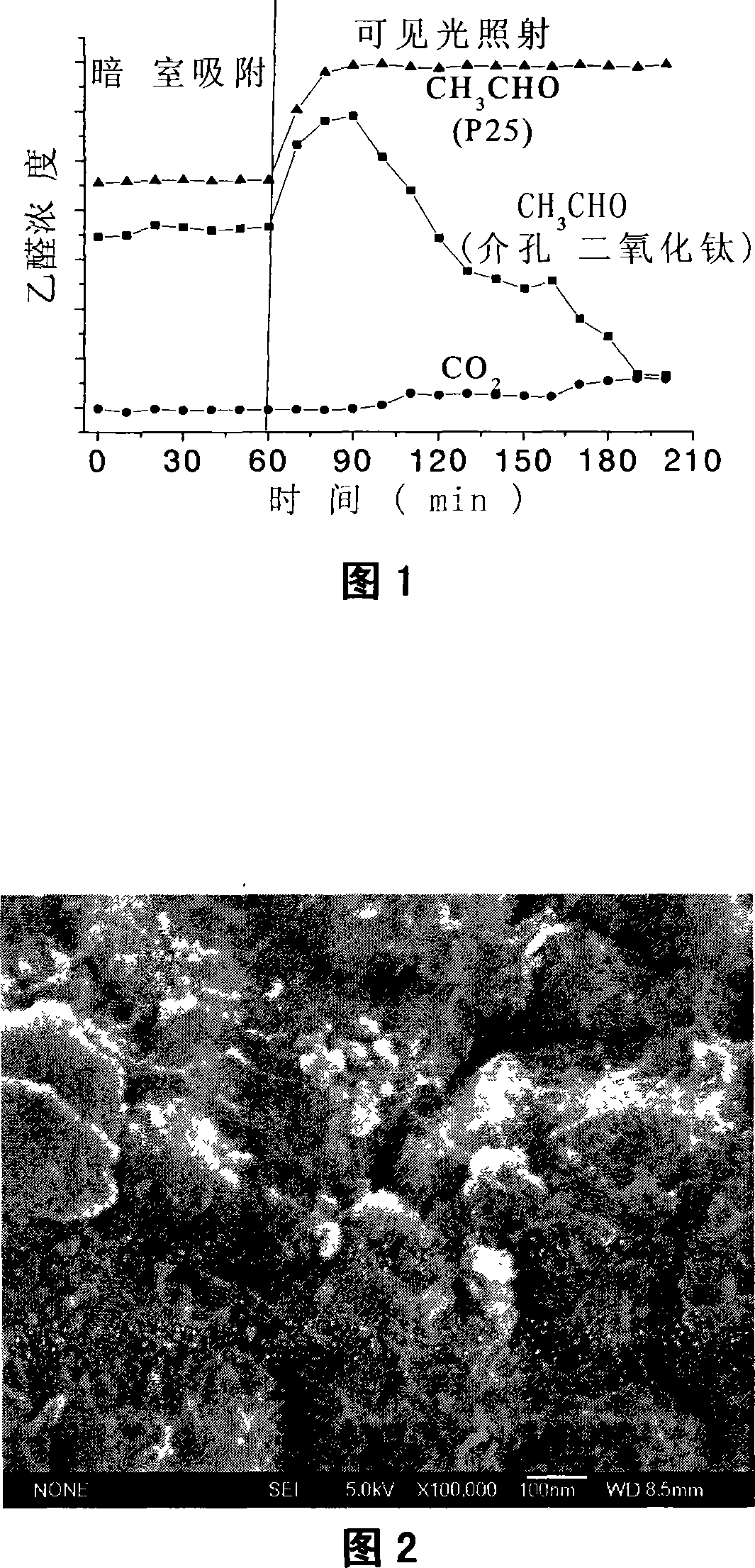

A technology of titanium dioxide and active substances, which is applied in the field of chemical engineering, can solve the problems of low solar energy utilization rate, restricting the preparation and application of carbon nanotubes, and reducing photocatalytic efficiency, etc., and achieves low production costs, increased reactivity, and facilitates diffusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Take 40 ml of ethanol in a beaker, add 5 ml of dispersant ethylene glycol, stir for 30 minutes, then add 3 g of estrocystin, and stir for 20 minutes. Add 4 grams of titanyl tetraisopropoxide after the estrocystin is completely dissolved, and add 50 ml of water dropwise after stirring for one hour. After the water addition was complete, it was stirred for 12 hours. Transfer the reactant in the beaker to a polytetrafluoroethylene crystallization bottle for crystallization for 4 days. Then the crystallized reactant is filtered, washed and dried. Finally, burn at 350°C for 2 hours to obtain light yellow mesoporous titanium dioxide powder.

Embodiment 2

[0025] Example 2: Get 50 milliliters of acetone in a beaker, add 8 milliliters of dispersant isopropanol, stir for 30 minutes, then add 2 grams of estrocystin, hypocrellin A and hypocrellin B mixture, and stir for 20 minutes minute. After the mixture is completely dissolved, add TiCl 4 5 g, and after stirring for one hour, 50 ml of water was added dropwise. After the water addition was complete, it was stirred for 12 hours. The reactant in the beaker was transferred to a polytetrafluoroethylene crystallization bottle for crystallization for 6 days. Then the crystallized reactants were filtered, washed, dried, and finally burned at 300°C for 4 hours to obtain light yellow mesoporous titanium dioxide powder.

Embodiment 3

[0026] Example 3: Take 40 milliliters of ethanol in a beaker, add 4 milliliters of dispersant ethylene glycol, stir for 30 minutes, then add 6 grams of a mixture of hypocrellin A and hypocrellin B, and stir for 20 minutes. After the mixture of hypocrellin A and hypocrellin B was completely dissolved, 3 grams of titanium oxide tetraisopropoxide was added, and after stirring for one hour, 50 ml of water was added dropwise. After the water addition was complete, it was stirred for 12 hours. Transfer the reactant in the beaker to a polytetrafluoroethylene crystallization bottle for crystallization for 3 days. Then the crystallized reactant is filtered, washed and dried. Finally, burn at 400°C for 6 hours. Obtain light yellow mesoporous titanium dioxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com