Silicon tungsten, phosphorus heteropoly tungstic acid load type catalyzer used for esterification reaction, manufacturing method and application thereof

A supported catalyst, phosphotungstic heteropolyacid technology, applied in physical/chemical process catalysts, molecular sieve catalysts, preparation of organic compounds, etc., can solve problems such as unsatisfactory ester yield and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 10%SiW 12 Preparation of / beta zeolite catalyst

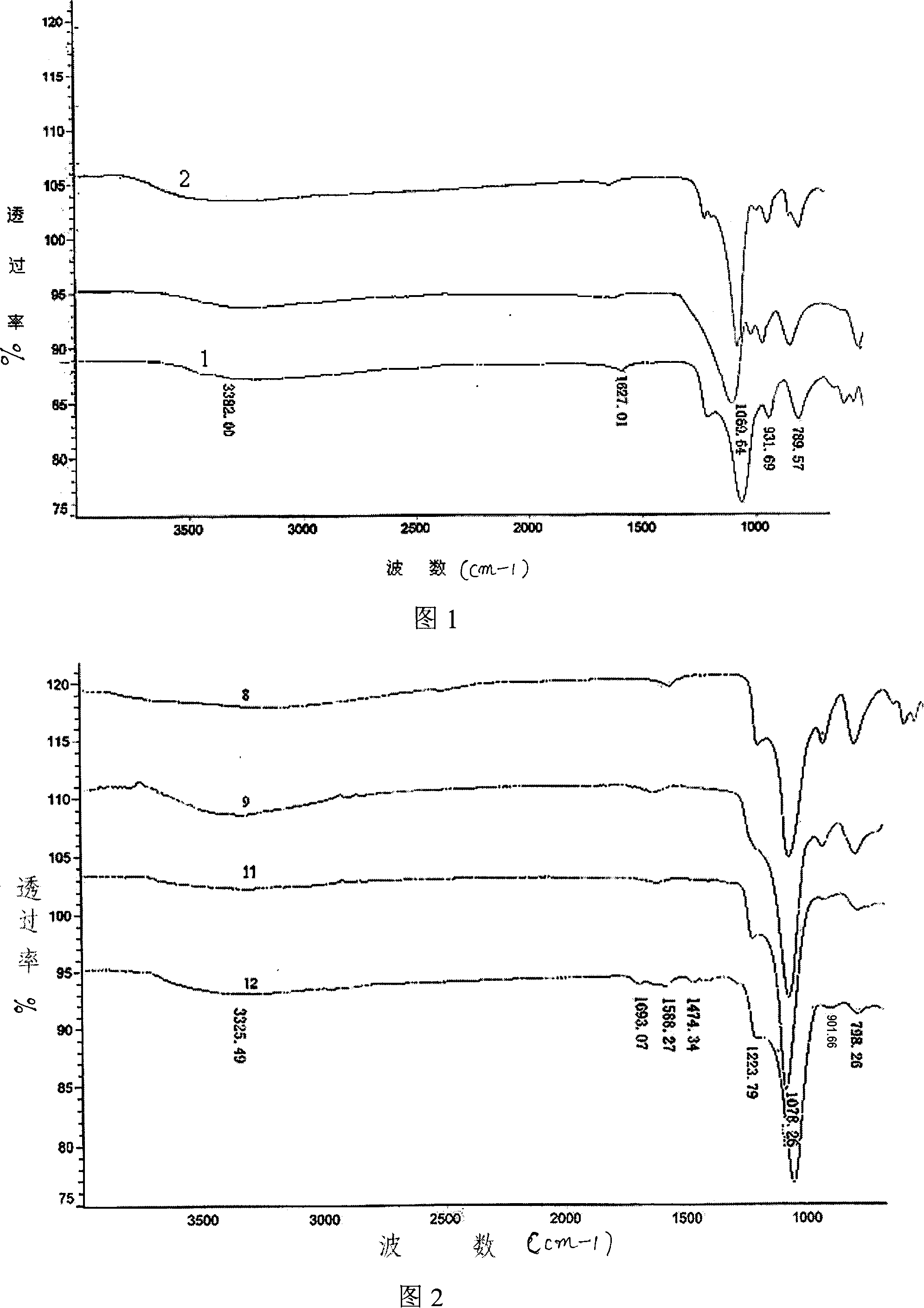

[0023] Weigh silicotungstic acid H with Keggin structure 3 SiW 12 o 40 xH2O 2g, dissolved in deionized water, weighed 18g of Hβ zeolite roasted at 400°C for 2 hours, (wherein Na 2 O≤0.2wt.%, total acid≥4.0×10 20 Sites / g, specific surface 607m 2 / g, the crystal grain is about 0.2μm), mixed with silicotungstic acid solution, the impregnation medium is deionized water, and the liquid-solid ratio (ratio of impregnation solvent volume to carrier mass) is 2.5ml / g. Shake and impregnate continuously in a constant temperature oscillator under normal temperature and pressure, carry out temperature program drying after 24 hours, rise to 120°C in 10 hours, continue drying at 120°C for 2 hours, and roast at 200°C for 2 hours to obtain 10% SiW 12 / beta zeolite catalyst. The obtained catalyst was characterized by IR and XRD, and the curve 9 in Fig. 2 is the IR spectrum of the catalyst. Since Keggin-type heteropolyacids have cha...

Embodiment 2

[0025] 20%SiW 12 Preparation of / beta zeolite catalyst

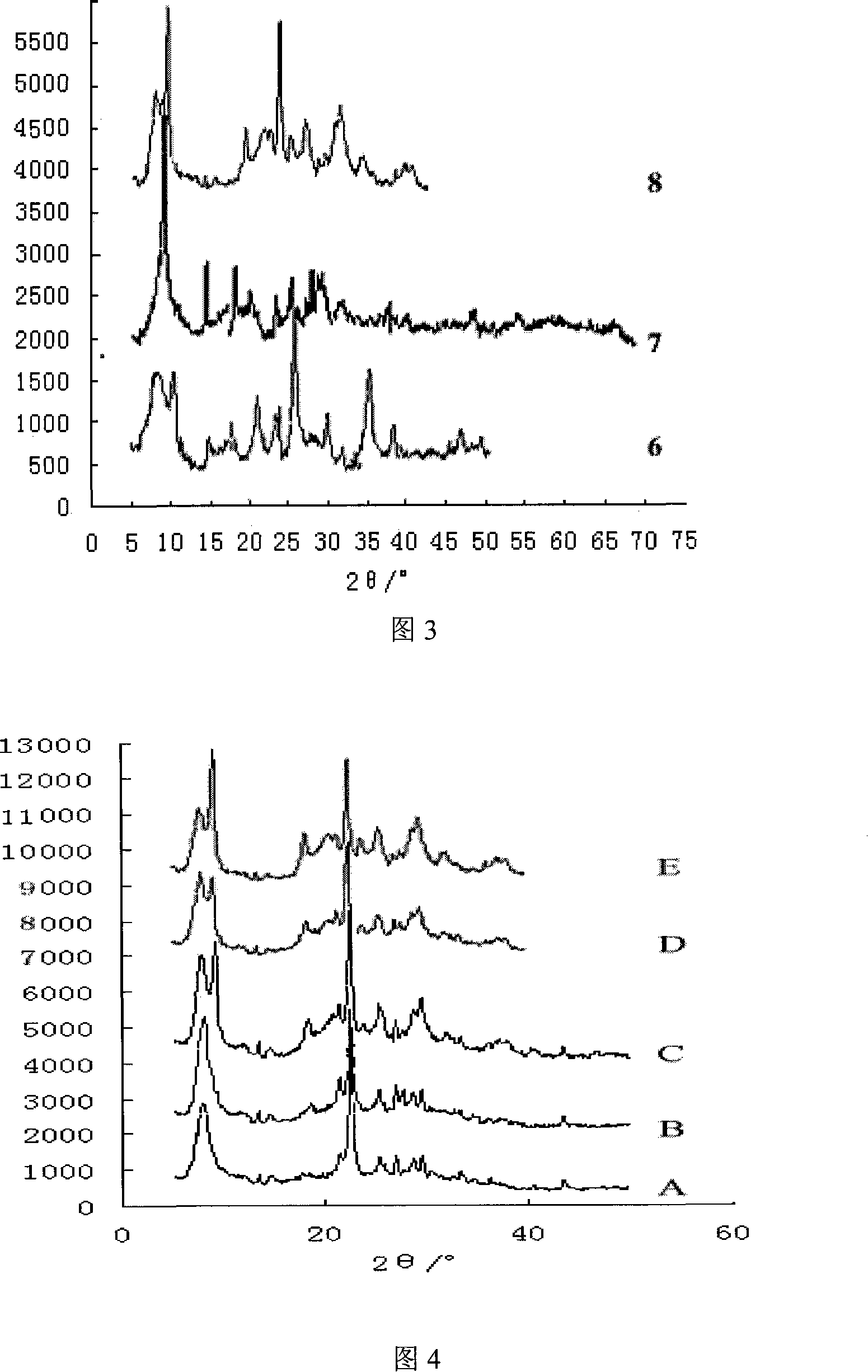

[0026] The amount of silicotungstic acid is 2g, the amount of Hβ zeolite is 8g, and the rest of the processing conditions and proportions are the same as in Example 1, that is, 20% SiW 12 / beta zeolite catalyst. Curve B in Figure 4 is the XRD pattern of the catalyst. In the figure, it can be observed that the XRD of the carrier Hβ zeolite has characteristic diffraction peaks at 2θ of 7.8°, 13.6°, 21.41°, 22.43°, 26.92°, and 29.60°. Dispersed on the surface of silica gel, so Keggin-type heteropolyacid characteristic diffraction peaks cannot be observed.

Embodiment 3

[0028] 30%SiW 12 Preparation of / beta zeolite catalyst

[0029] The amount of silicotungstic acid is 3g, the amount of Hβ zeolite is 7g, and the remaining processing conditions and proportions are the same as in Example 1, that is, 30% SiW 12 / beta zeolite catalyst. Curve C in Figure 4 is the XRD pattern of the catalyst. In addition to the characteristic diffraction peaks at 2θ of 7.8°, 13.6°, 21.41°, 22.43°, 26.92°, and 29.60° in the XRD of the carrier Hβ zeolite, due to the increase in loading, the Keggin structure heteropolyacid Characteristic peaks began to appear, and four characteristic peaks at 2θ of 8.28°, 8.90°, 10.27° and 28.9° were observed. Thanks to SiW 12 The interaction with the carrier makes the diffraction peaks of the carrier between 2θ=10-60° become diffuse or disappear. For example, the XRD diffraction peak at 7.8° appears branched, which is obviously the heteropoly acid at 8.28°. XRD diffraction peaks. These spectra show that SiW 12 It is highly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com